Process for synthesizing nano barium ferrite powder by microwave induction and low-temp combustion

A low-temperature combustion synthesis, barium ferrite technology, applied in the direction of inorganic material magnetism, can solve the problem of unretrieved powder, etc., achieve the effect of low equipment requirements, narrow particle size distribution, and improved magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

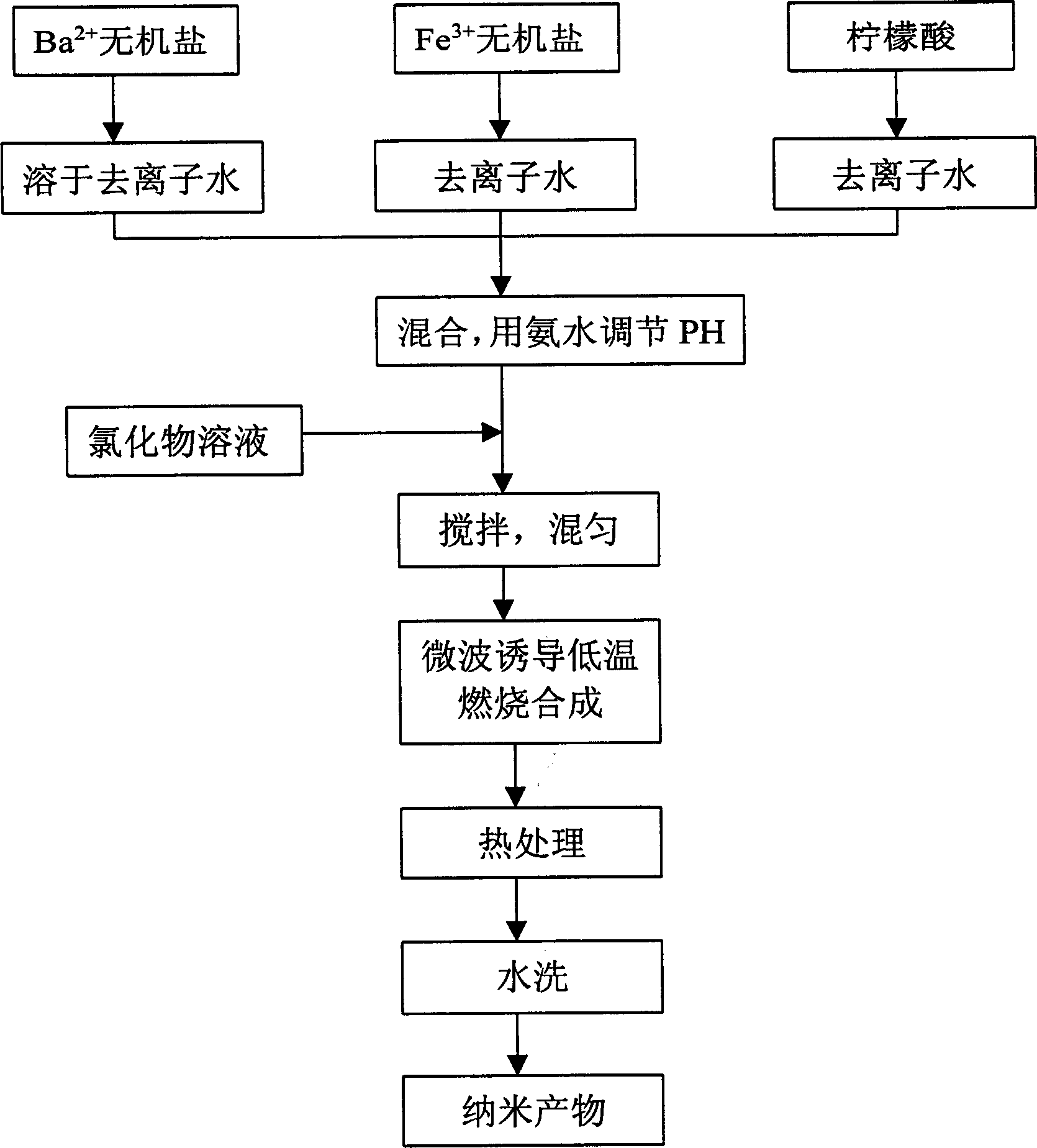

Method used

Image

Examples

Embodiment 1

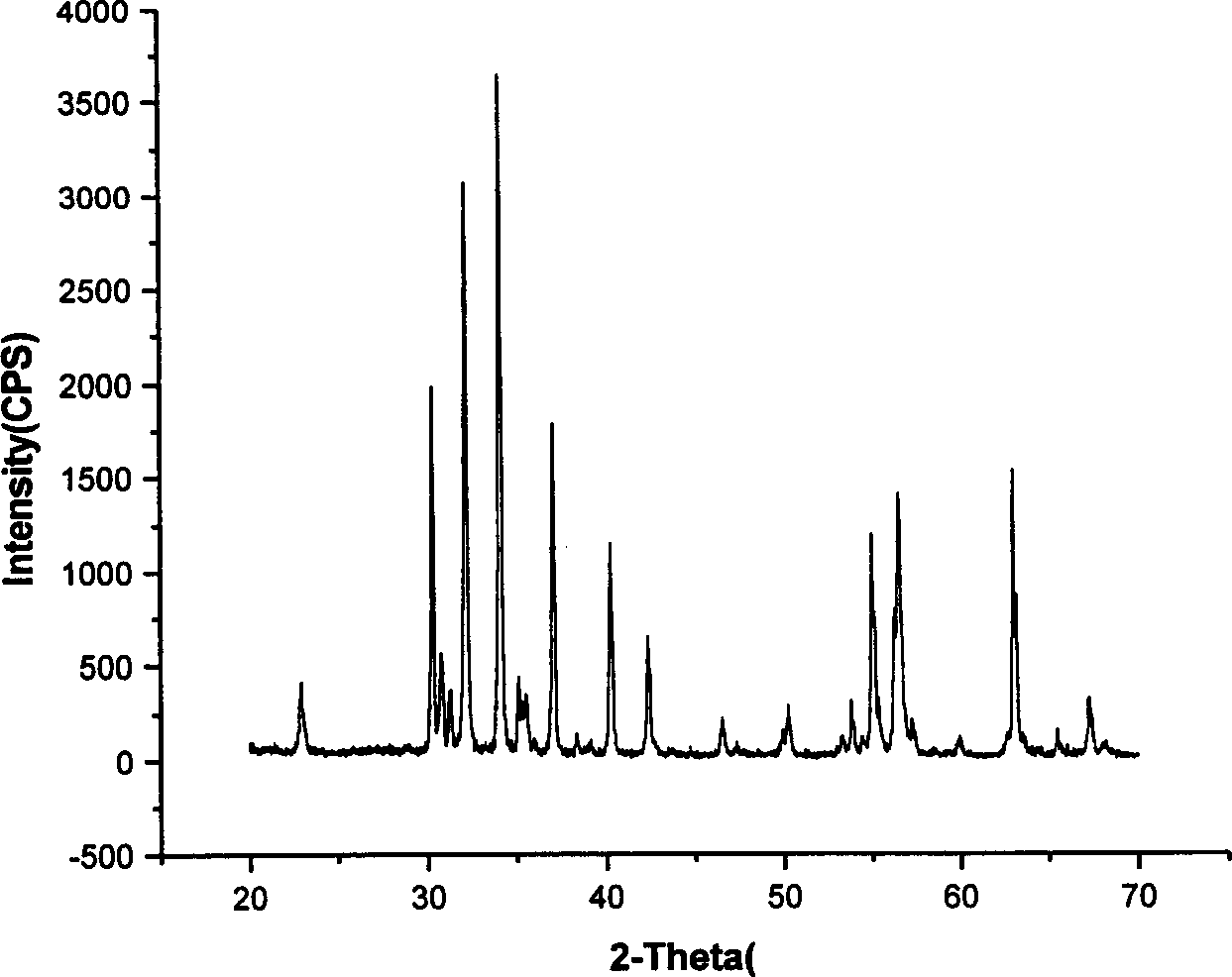

[0028] Use barium nitrate, ferric nitrate, citric acid and chloride as raw materials, according to Ba 2+ : Fe 3+ : citric acid: chloride molar ratio=1: 11.5: 30: 1 (chloride is the mixture of NaCl / KCl molar ratio=1: 1) batching, and method is as follows: respectively with nitrate, citric acid, be dissolved in deionized water , to make a solution, stir continuously after mixing, adjust the pH to 7 with ammonia water, then add chloride solution, stir well, and place it in a microwave cavity for heating. The microwave frequency is 2450MHz, and the input power is 500W. The solution first boils and bubbles, and as the water evaporates, a gel is formed. When reaching a certain temperature, the gel starts to ignite and burn, and a loose, foamy powder is obtained. The above powder was heat-treated at 700°C in air for 4 hours, washed with water to remove chlorides, and the final product was obtained. Its magnetic properties are: specific saturation magnetization σ s =55.79emu / g, i...

Embodiment 2

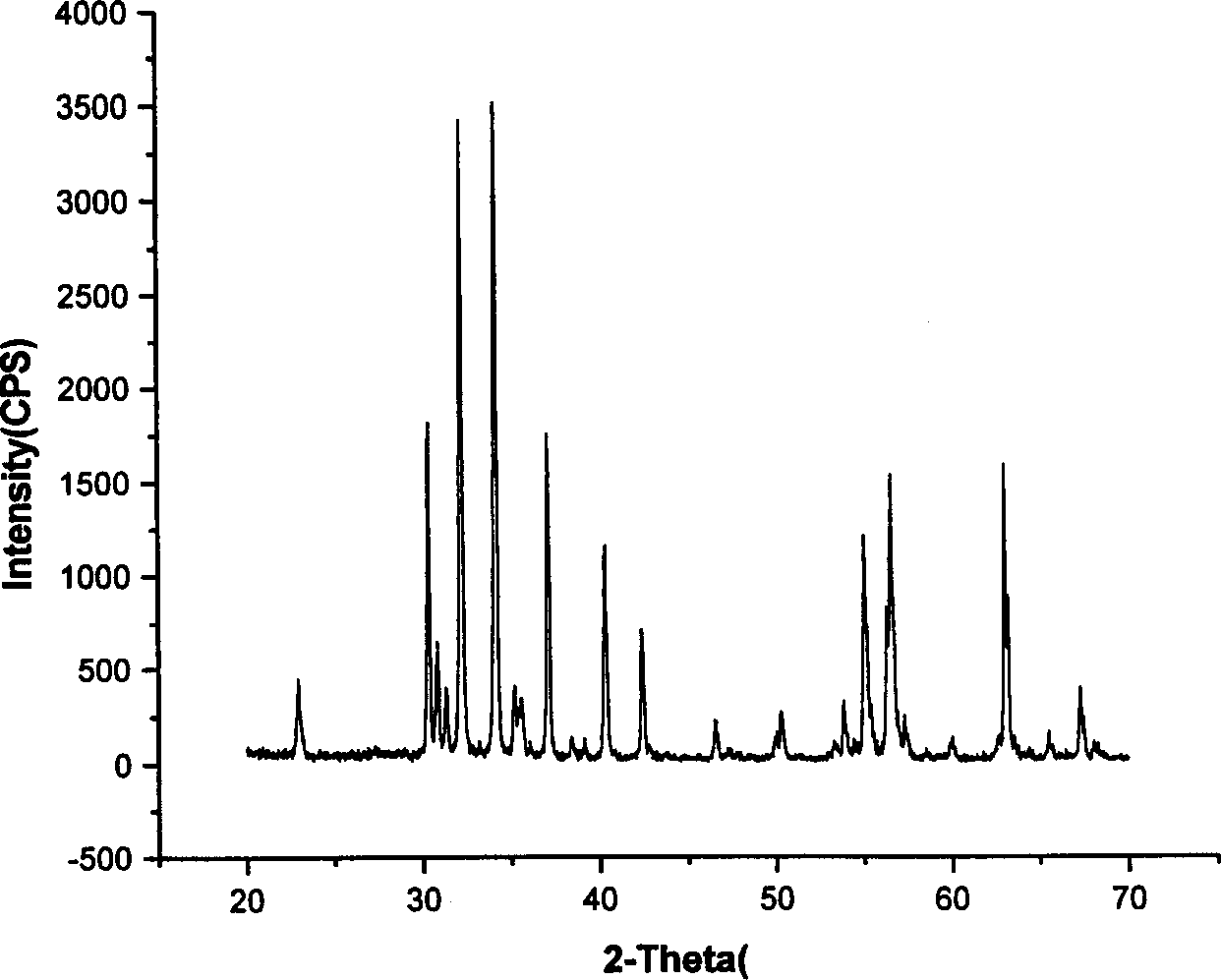

[0030]Use barium nitrate, ferric nitrate, citric acid, sodium chloride as raw materials, according to Ba 2+ : Fe 3+ : citric acid: sodium chloride = 1: 11.5: 26: 3 (molar ratio) ingredients, the method is as follows: respectively dissolve nitrate, citric acid, and deionized water to make a solution, stir continuously after mixing, and adjust with ammonia water PH is equal to 5, then add sodium chloride solution, stir well, and heat in a microwave cavity. The microwave frequency is 2450MHz, and the input power is 500W. The solution first boils and bubbles, and as the water evaporates, a gel is formed. When reaching a certain temperature, the gel starts to ignite and burn, and a loose, foamy powder is obtained. The above-mentioned powder is rapidly heated to 800°C, kept for 50 minutes, washed with water to remove chlorides, and the final product is obtained. The magnetic properties are: specific saturation magnetization σ s =66.79emu / g, intrinsic coercive force jHc=5.08KOe....

Embodiment 3

[0032] Using barium carbonate, ferric nitrate, citric acid, sodium chloride as raw materials, according to Ba 2+ : Fe 3+ : citric acid: sodium chloride = 1: 12: 15: 2 (molar ratio) batching, the method is as follows: respectively dissolve nitrate, citric acid, and deionized water to make a solution, stir constantly after mixing, adjust with ammonia water When the pH is equal to 6, add sodium chloride solution, stir well, and heat in a microwave cavity. The microwave frequency is 2450MHz, and the input power is 500W. The solution first boils and bubbles, and as the water evaporates, a gel is formed. When reaching a certain temperature, the gel starts to ignite and burn, and a loose, foamy powder is obtained. The above-mentioned powder was heat-treated at 800°C for 2 hours in the air and then washed with water to remove chlorides to obtain the final product. The magnetic properties are: specific saturation magnetization σ s =64.79emu / g, intrinsic coercivity jHc=4.587KOe. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com