Composite lining cloth and its production method

A technology of interlining and base fabric, applied in the field of composite interlining and its manufacturing, can solve the problems of limited effect and achieve the effect of three-dimensional effect, excellent elasticity and hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

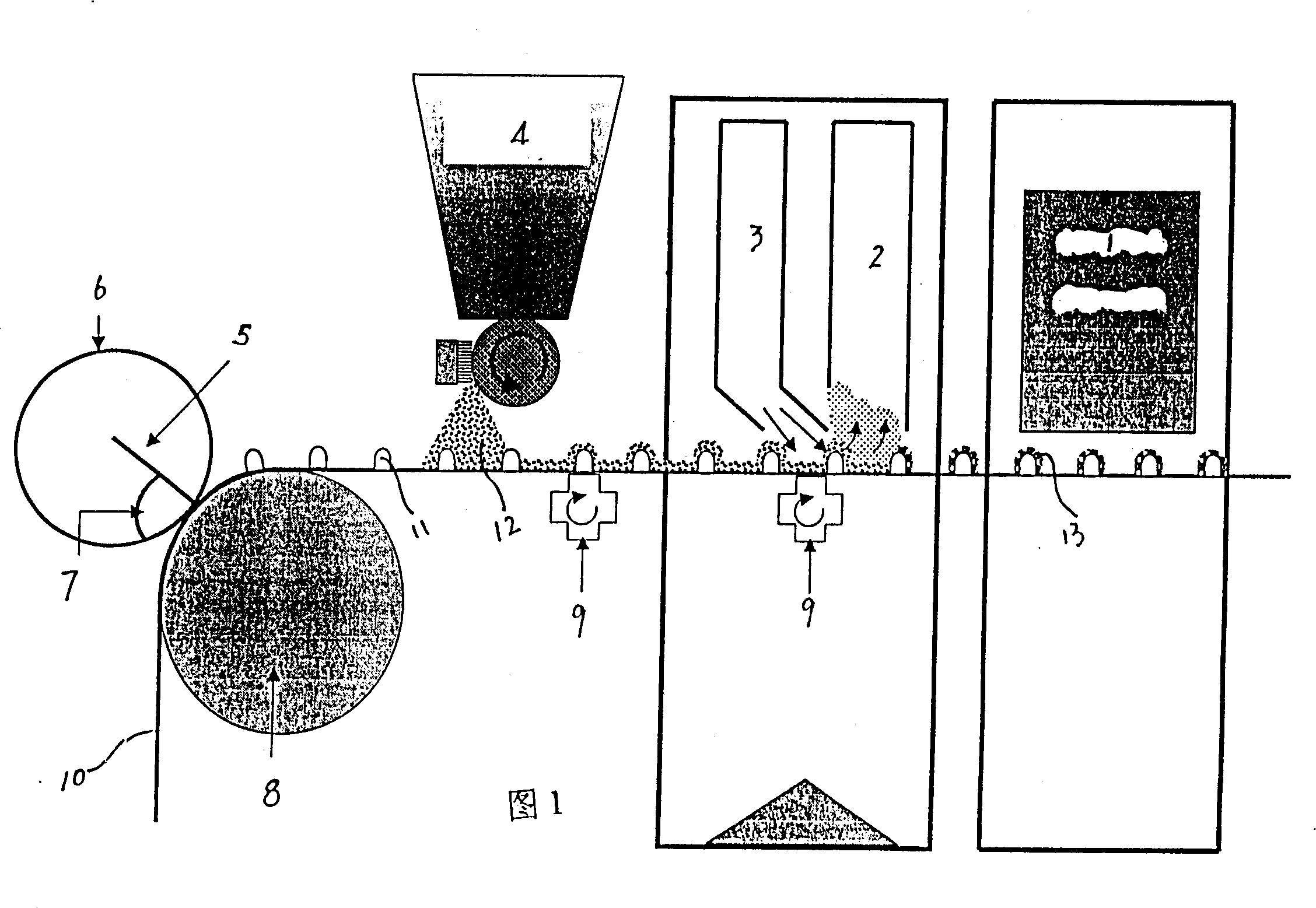

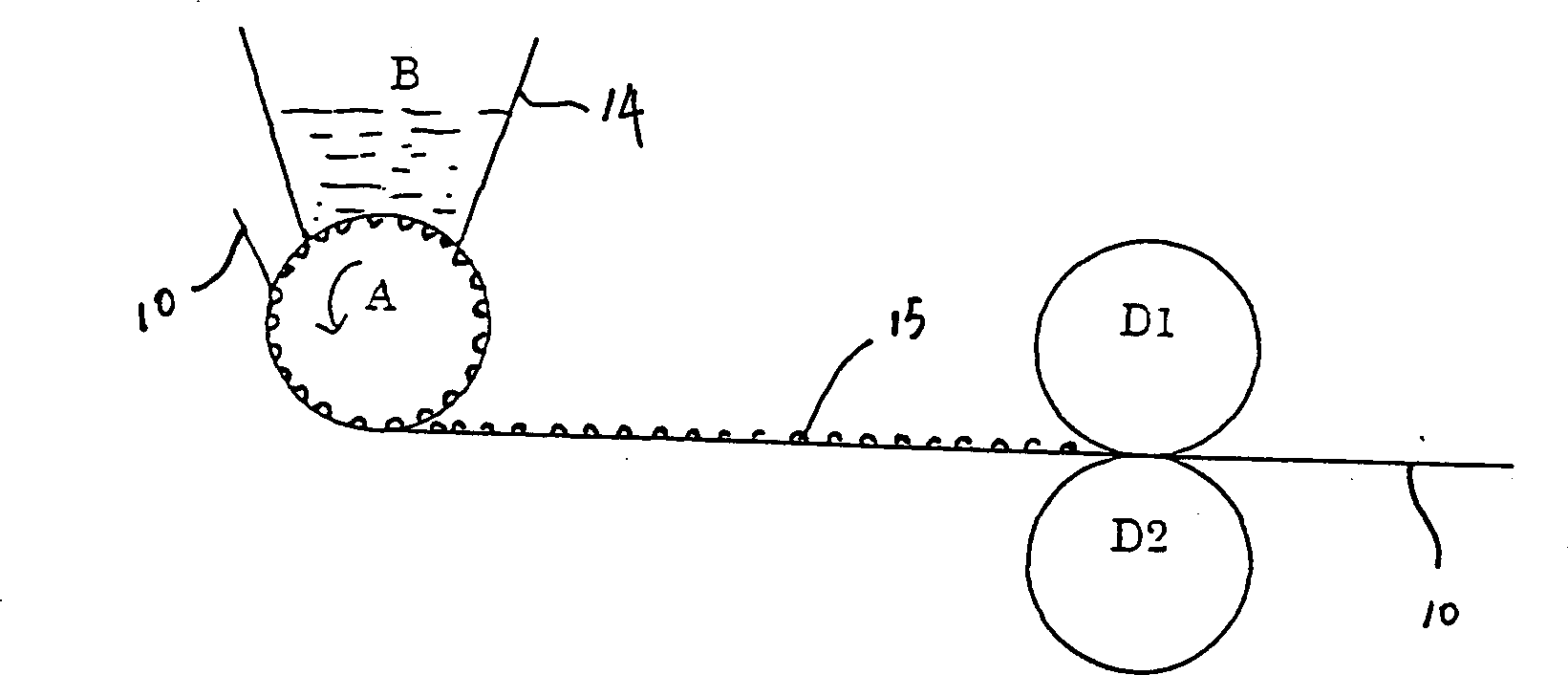

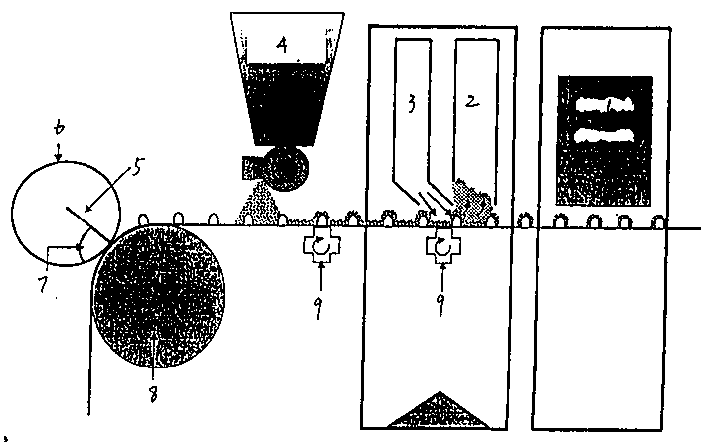

Method used

Image

Examples

Embodiment 1

[0058] The warp of the base fabric is a yarn made of polyester or nylon long fibers, and the weft is a yarn made of polyester cotton or viscose fiber, rayon, and acrylic resin, and then spun. .

[0059] Or one of the warp threads or weft threads of the base fabric is made of long fibers made of all polyester or all nylon, and the other thread is made of short fibers made of short fibers and long fibers made of long fibers. made.

Embodiment 2

[0061] 1. Raw material: T22682, specification: 50D / 48F*R20+150D, density: 71*34, width: 147 cm, composition: T / R: 57 / 47, raw material characteristics: warp thread is 50D polyester long fiber, weft thread is R20.T150D fibers are interwoven, which has the soft feel of polyester long fiber fabrics and the scratchy characteristics of blended fabrics, and also improves the air permeability of the fabrics.

[0062] 2. Scouring: Add the scouring liquid made of water and additives into the liquid tank of the scouring machine, make the base cloth soak the scouring liquid, and then enter the scouring container—the reaction tower for scouring. The temperature of the reaction tower is 80°C. The time is 60 minutes. The additives added in the refining solution are 1 g / L of sodium hydroxide, 10 g / L of hydrogen peroxide, 3 g / L of hydrogen peroxide stabilizer, 1 g / L of scouring detergent, and 1 g / L of metal ion chelating agent.

[0063] 3. Dyeing: Add water and auxiliaries to the dyeing liquo...

Embodiment 3

[0069] 1. Raw material: T22682, specification: 50D / 48F*R20+150D, density: 71*34, width: 147 cm, composition: T / R: 57 / 47, raw material characteristics: warp thread is 50D polyester long fiber, weft thread is R20.T150D fibers are interwoven, which has the soft feel of polyester long fiber fabrics and the scratchy characteristics of blended fabrics, and also improves the air permeability of the fabrics.

[0070] 2. Scouring: Add the scouring liquid made of water and additives into the liquid tank of the scouring machine, make the base cloth soak the scouring liquid, and then enter the scouring container—reaction tower for scouring. The temperature of the reaction tower is 120°C. Time 40 minutes. Addition of additives in the scouring liquid is 3 g / L of sodium hydroxide, 20 g / L of hydrogen peroxide, 8 g / L of hydrogen peroxide stabilizer, 3 g / L of scouring detergent, and 3 g / L of metal ion chelating agent.

[0071]3. Dyeing: Add water and auxiliaries to the dyeing liquor in the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com