Formation of colored stero pattern inside color-less transparent glass

A technology of transparent glass and glass, applied in the direction of imitating three-dimensional effect patterns, special patterns, patterns characterized by light projection effect, etc., can solve the problem of single pattern color and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

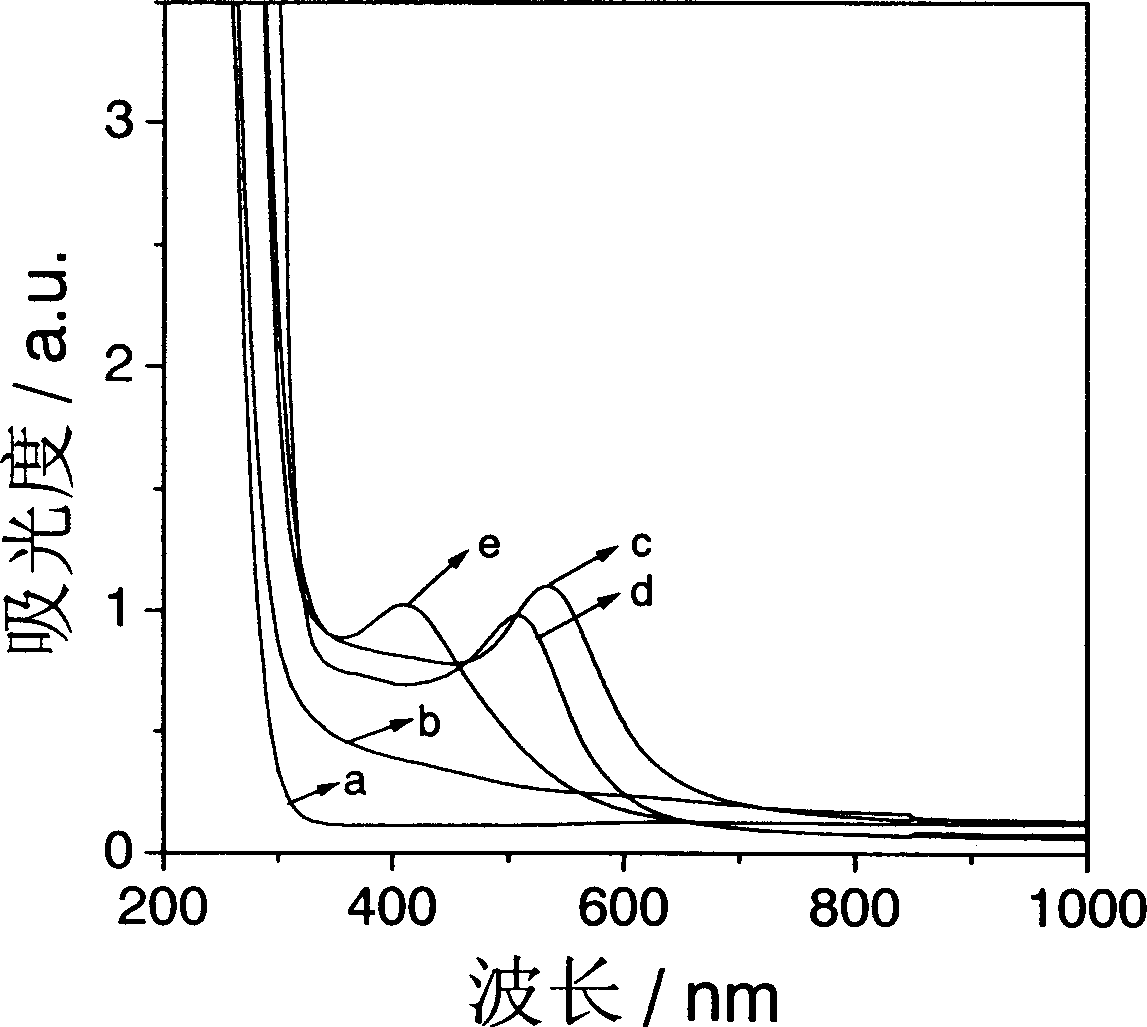

[0022] Example 1: Select the glass composition as 0.2% Au by weight % according to the above specific method 2 O, 0.5% CeO 2 , 80% SiO 2 , 9.3% CaO, 10% Na 2 O. Polished glass surface. Choose a laser beam with a laser pulse width of 100 fs and a wavelength of 800 nm, and a laser pulse frequency of 1 KHz. Use a three-dimensional mobile platform and computer software to control the laser irradiation and write two patterns, that is, first focus and irradiate the 300mW laser with a 50 times (NA=0.80) lens on the upper right corner of the glass and engrave it into the first pattern pattern. Then focus the laser with an average power of 300mW with a 10x (NA=0.30) objective lens and irradiate it onto the upper left corner of the polished glass to engrave the second pattern. In the lower left corner, use a 5x (NA=0.10) lens to focus and irradiate a 1mW laser to engrave the third pattern. All patterns are gray-black. After heat treatment at 600°C for 5 minutes, the first pat...

example 2

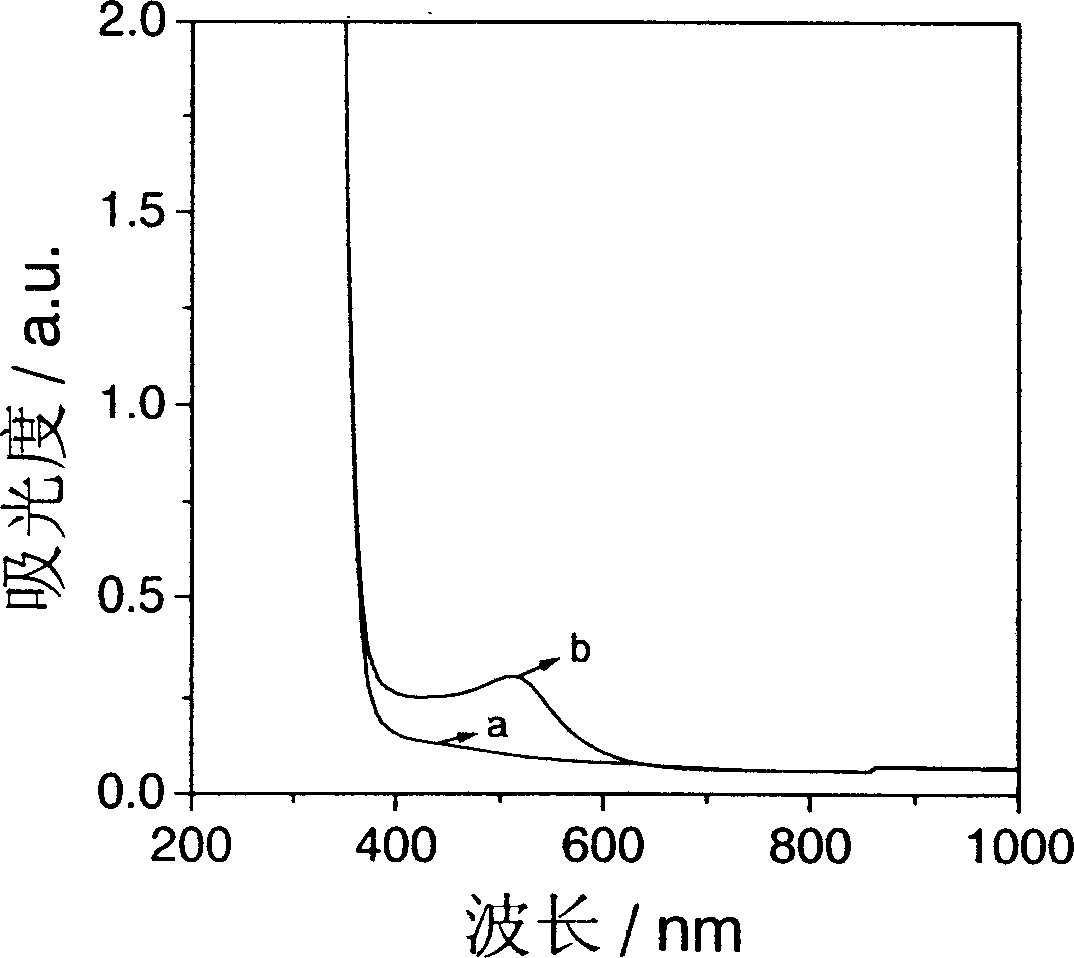

[0023] Example 2: According to the above specific method: select the glass composition, which is 0.3% Au by wt% 2 O, 0.1% Sb 2 o 3 , 55% SiO 2 , 6%Na 2 O, 8%K 2 O, 30%PbO, 0.6Al 2 o 3 . Polished glass surface. Choose to irradiate with neodymium-doped yttrium aluminum garnet (Nd:YAG) frequency-doubled laser with a wavelength of 532 nm, a pulse width of 10 nanoseconds (ns), and a repetition rate of 30 Hz. Use the three-dimensional mobile platform and computer software to control the laser beam to write the pattern. The average power of the laser is 450mw. The written pattern is colorless. After heat treatment at 350°C for 30 minutes, the pattern turns pink, and the absorption spectrum is as follows figure 2 shown. Wherein, the line a is the absorption spectrum of the area not irradiated by the nanosecond laser, and the line b is the absorption spectrum of the area irradiated by the nanosecond laser and heat-treated.

example 3

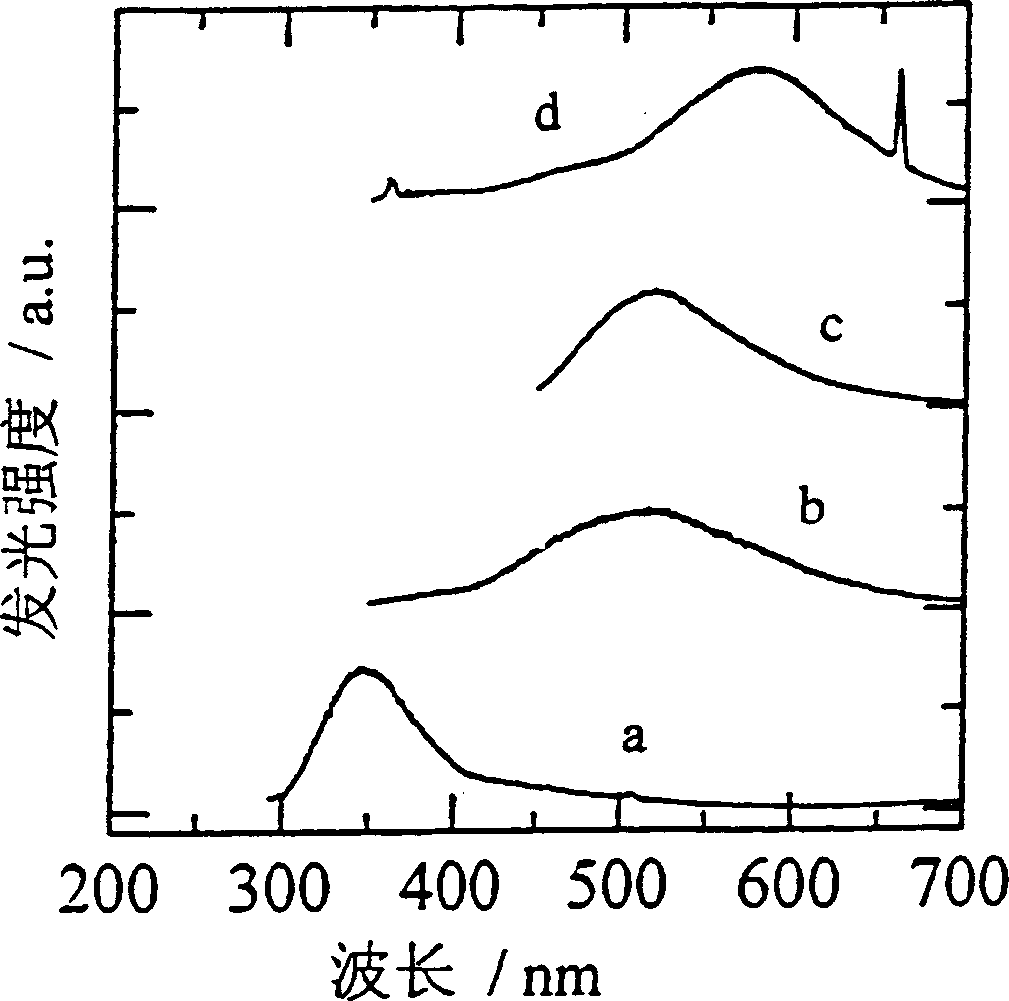

[0024] Example 3: According to the above specific method, select the glass composition, which is 2% Ag by weight 2 O, 0.1% SnO, 70% SiO 2 , 4.5% CaO, 5% BaO, 15% Na 2 O, 1.2% MgO, 1.2% ZnO, 1% Al 2 o 3Polished glass surface. Use a 20x (NA=0.46) objective lens to focus and irradiate the femtosecond laser with a wavelength of 800nm (pulse width 200fs, pulse frequency 200KHz, average power 100mW) into the glass, and engrave a butterfly pattern inside the glass. The pattern is grey. It was then heat-treated at 500°C for 10 minutes. Gray butterflies turn yellowish. Observation under the transmission electron microscope showed that nano-silver particles were precipitated. The yellowish color is due to the surface plasmon absorption of the Ag nanoparticles. Then carve the beetle pattern in another position in the sample. Under 254nm ultraviolet irradiation, the part not irradiated by the laser (such as image 3 Shown in a) observed that originating from Ag + 360nm lumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com