Non-woven fabric of down with crimped fiber and its production process

A technology of non-woven fabrics and processing methods, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of high-quality products, such as difficult, uneven product structure, poor surface flatness, etc., to improve performance and value. , static state and stable content, good windproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

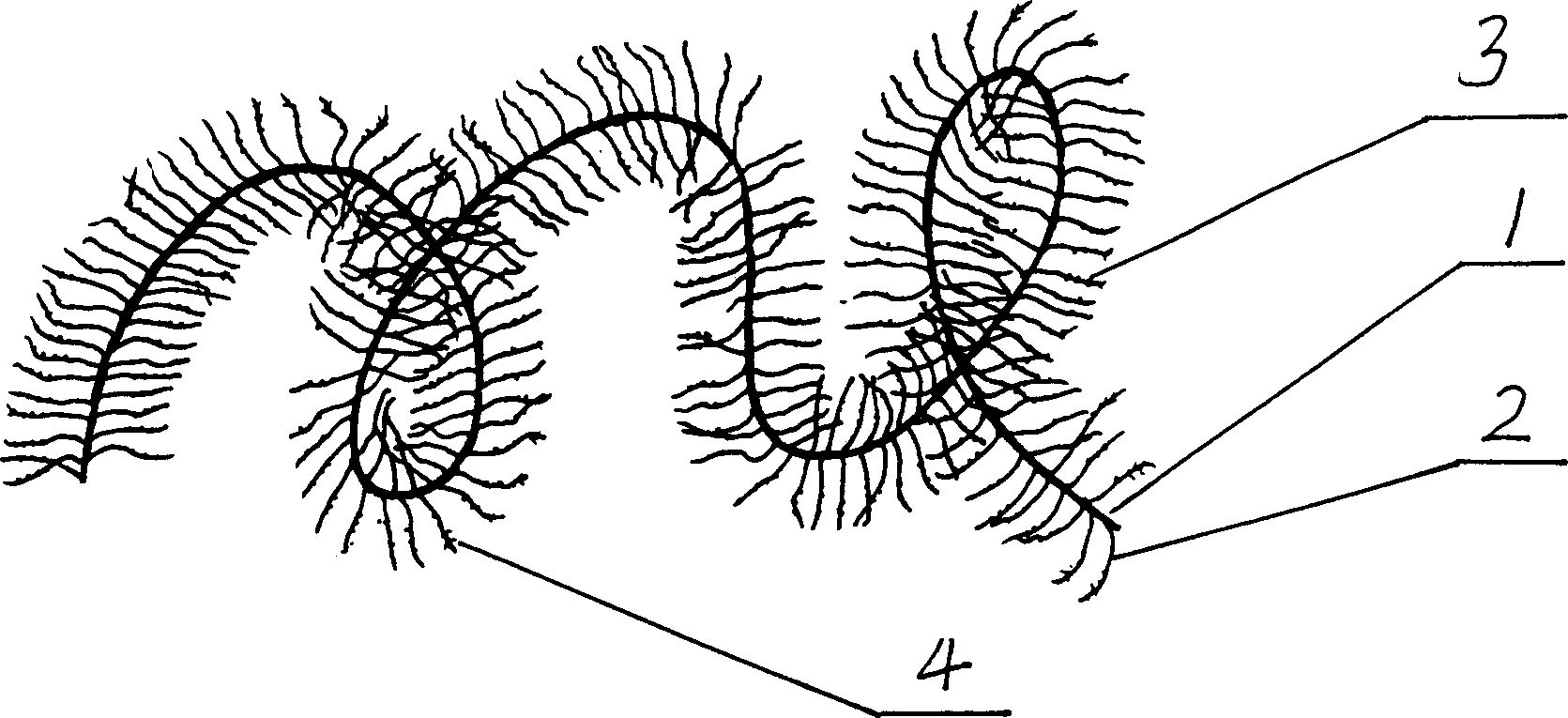

[0028] Example 2 as figure 1 .2.4.7 100% of fibrous feathers and feathers

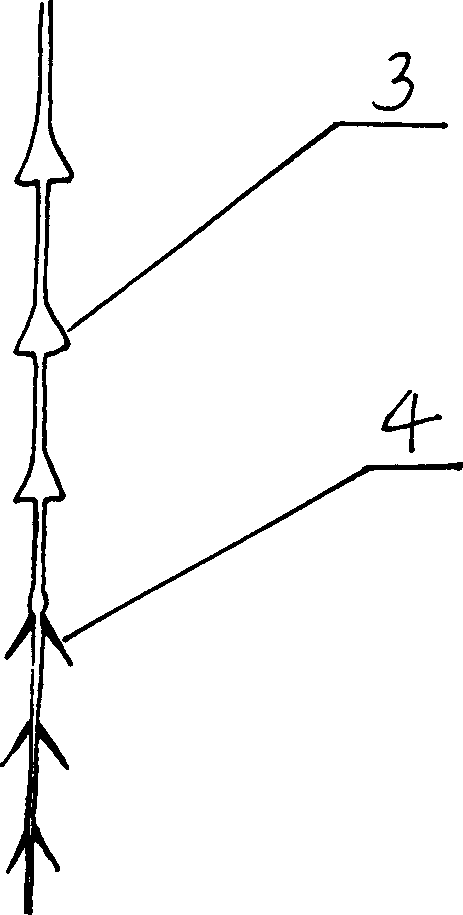

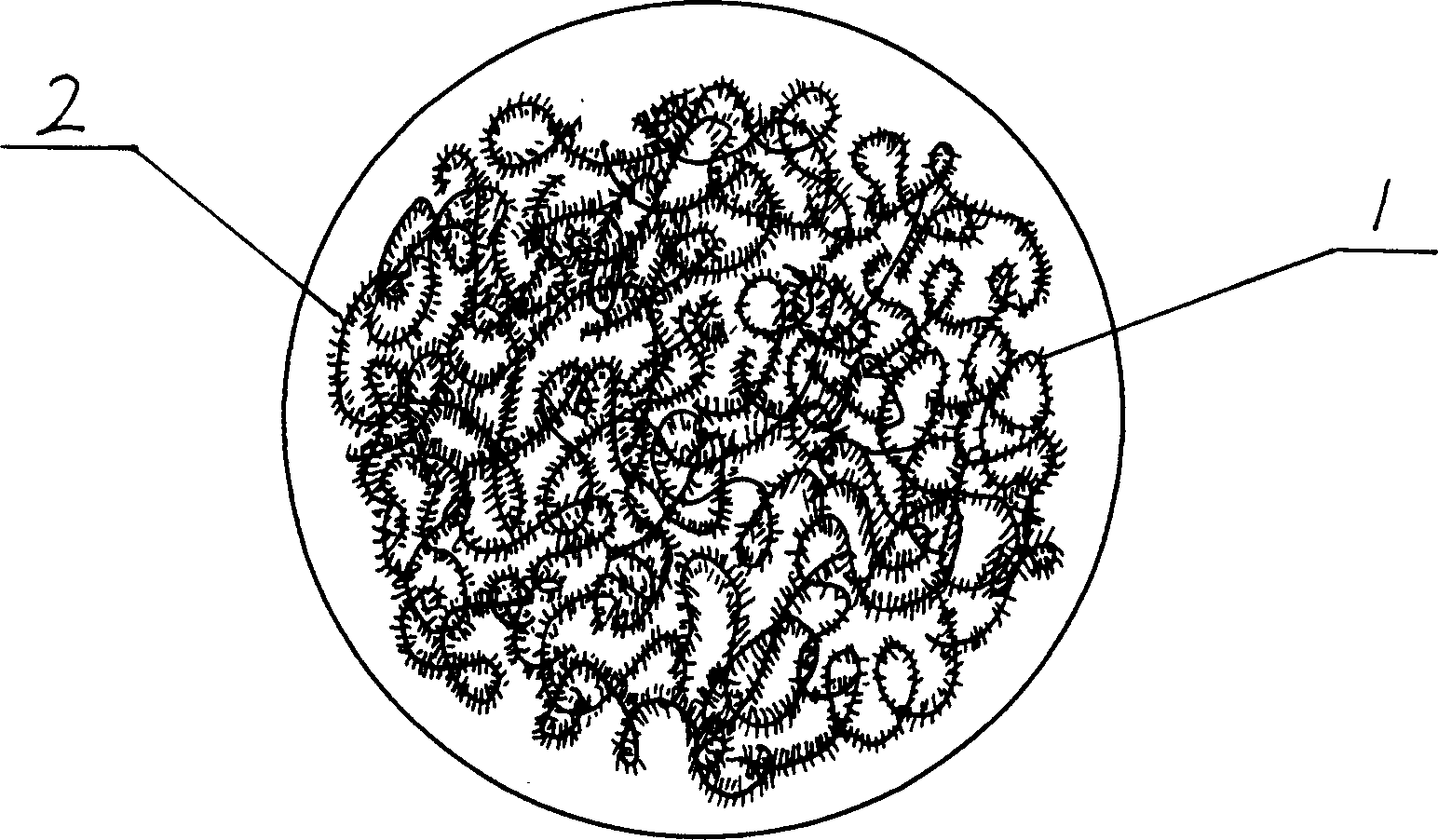

[0029] The non-woven fabric is composed of fibrous feather feather branches that are thicker and harder than down silk, and the feather silk feather branches have the advantages of higher tensile strength and longer down feather branches than the down silk feather branches. The fibrous feather feathers are composed of the curled main stem 1, the feather branch 2 on the main stem 1, the nodules 3 and / or the spines 4 on the feather branch 2. At the same time, it is a composite structure that is intertwined and bonded at the intersection 5 by the adhesive. The feather silk is chemically softened and denatured to make the thicker and harder feather silk soft and slightly curled, and then mechanically rubbed and curled to make the curl meet the required requirements, and then filled into the extrusion hot oven and sealed. The temperature of the box is adjusted to 130°C, and the time is set for 5 minutes, ...

example 3

[0030] Example 3 as figure 1 .2.6.8 80% fibrous feather and feather branches, 20% heat-melt bonded fibers

[0031]The fibrous feather feather branches are formed by the crimped main stem 1, the feather branch 2 on the main feather stem 1, the nodules 3 and / or spines 4 on the feather 2 and the heat-melt-bonded fibers 6. It is a composite structure of intertwining and intertwining and bonding together, and the intersecting points 5 of which are intertwined and cohesive are bonded together. The fibrous feather feather branches are deformed by mechanical rubbing, and then filled into the extrusion hot oven to seal, the temperature of the hot oven is adjusted to 170 ° C, and the setting time is 2 minutes, so that the feather branches form a stereotyped curl shape, and then the 80% of the feather and feather branches are mixed with 20% of the opened hot melt adhesive fibers, and the mixed material is combed, air cluttered into a network, and heated to make the hot melt adhesive fib...

example 4

[0032] Example 4 is shown in the figure: 1.2.5.8 Fibrous feather down branch 50% viscose fiber 50%

[0033] The non-woven fabric is composed of curled fibrous feather feather branches and viscose fibers, and the fibrous feather feather branches are composed of a curled feather branch main rod 1, feather branchlets 2 on the feather branch main rod 1, The nodules 3 and / or spines 4 on the feather twigs 2 and the viscose fibers 6 form a sheet-like composite structure that is evenly intertwined with each other. The fibrous feather and feather branches are softened and curled by chemical softening and denaturation treatment, and mixed with viscose fibers in the stated proportion; The existing process is shaped to form a fibrous feather down branch and viscose fiber blended non-woven fabric. The non-woven fabric has the advantages of compactness, high heat retention rate, good surface flatness, good moisture absorption, good air permeability, etc., and is suitable for making air-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com