Ceramic and its making method

A manufacturing method and ceramic technology, applied in the field of ceramics and their manufacturing, can solve the problems of damage to mechanical strength and particle characteristics and disadvantages of inorganic functional materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

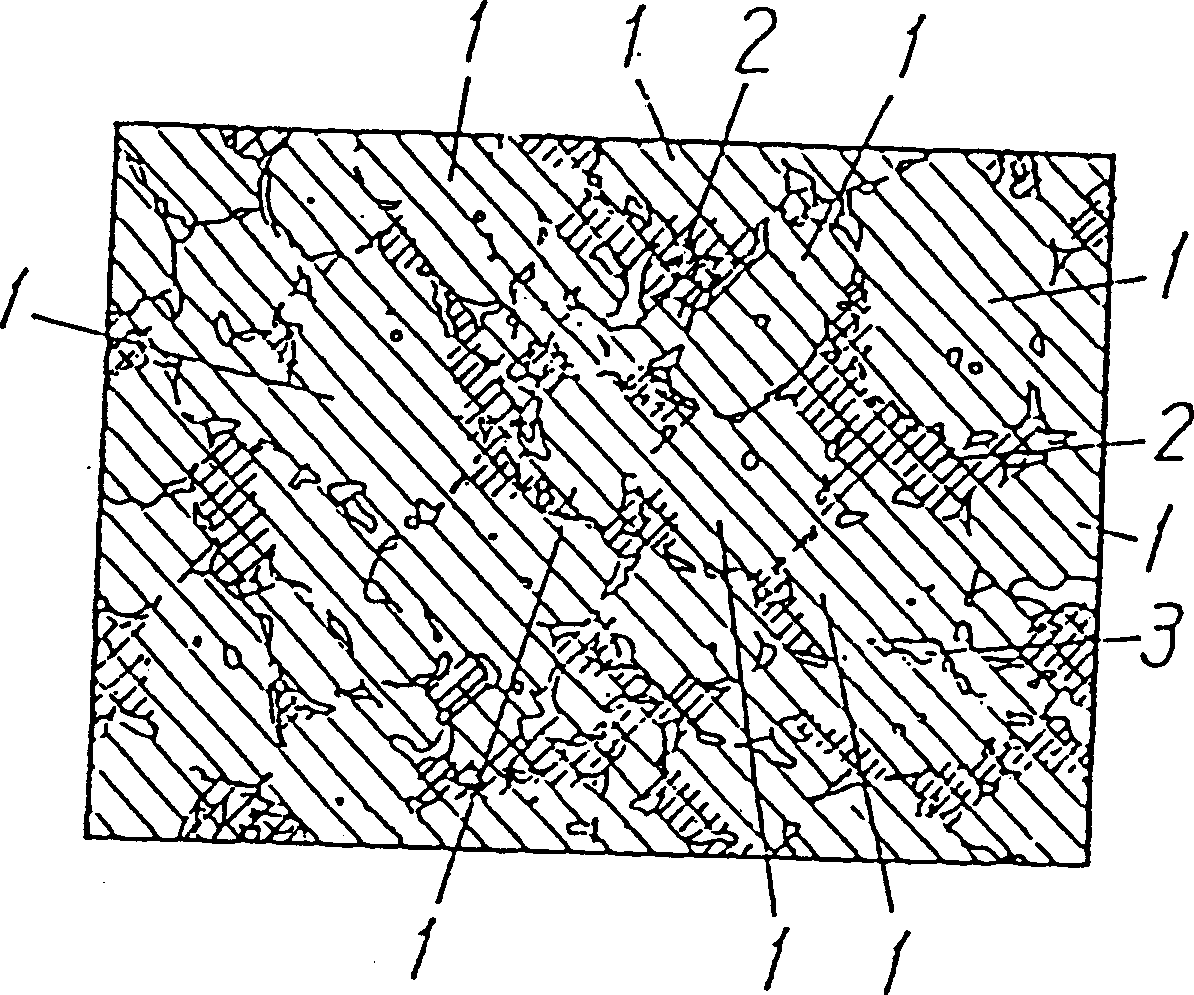

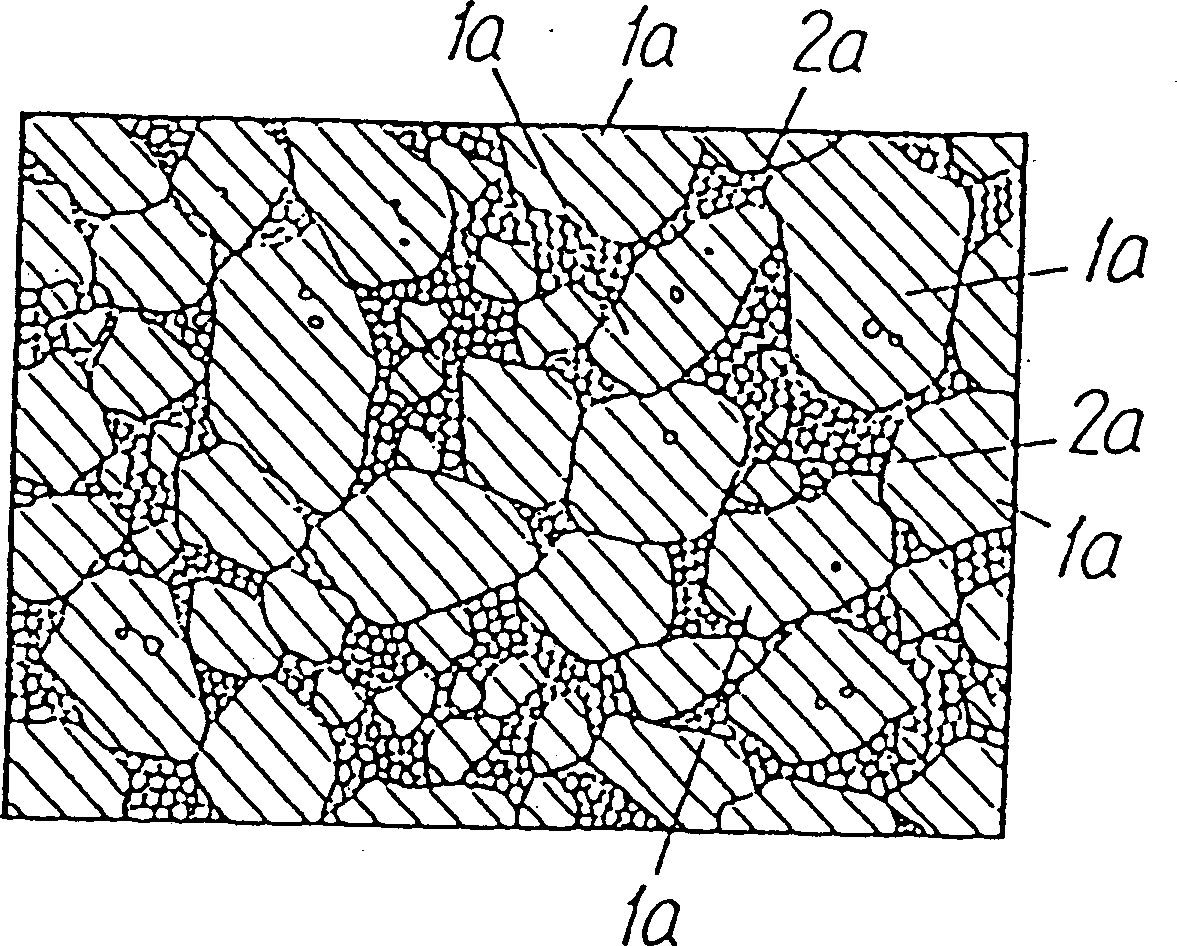

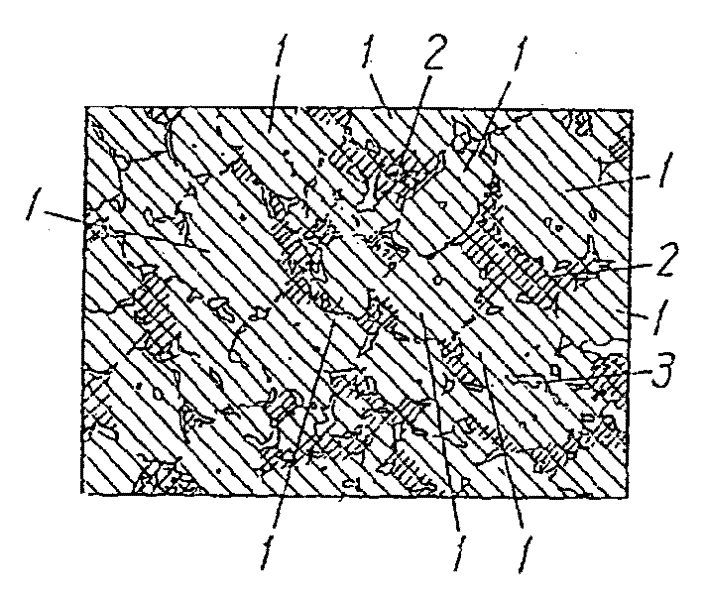

[0024] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. figure 1 Shown is an enlarged view of the internal structure of a flat-plate ceramic as an example of the present invention. The ceramic is composed of inorganic functional material particles 1 and composite oxide particles 2 located between the innumerable inorganic functional material particles 1 . like figure 2 As shown in the figure, when the inorganic functional material powder 1a is mixed with a mixture 2a of inorganic compound fine particles containing at least one metal fine particle, it is fired, as in figure 1 As shown, complex oxide particles 2 are formed between inorganic functional material particles 1 . In the figure, 3 denotes a pore.

[0025] Moreover, the manufacturing method of the ceramics of this invention has the following three processes.

[0026] To form complex oxide 2, such as figure 2 As shown in the figure, a mixture 2a of at...

Embodiment 2

[0049] Hereinafter, a second embodiment of the present invention will be described. The composition of the ceramic used in Example 2 and its manufacturing method is substantially the same as that of Example 1 and is omitted here.

[0050] to form MgAl 2 O 4 It is a spinel composite oxide in which Al particles and MgO particles are mixed in a weight ratio of 57.3:42.7, and the mixed powder is used as a mixture of inorganic compound fine particles. This mixture of inorganic compound fine particles was mixed with 30 parts by weight of alumina powder (100 parts by weight) and fired at 1600°C to obtain a ceramic (Sample 21). The properties including thermal conductivity of this sample are shown in Table 3.

[0051] Dimensional change rate (%)

Porosity (%)

Thermal conductivity (W / m·k)

Sample 21

0.0

9

18

Comparative Sample 1

0.0

16

10

[0052] Here, Comparative Sample 1 is a ceramic in which only Al particles a...

Embodiment 3

[0055] Hereinafter, a third embodiment of the present invention will be described. The composition of the ceramic used in Example 3 and its manufacturing method is substantially the same as that of Example 1, and is omitted here.

[0056] to form Si 2 Al 6 O 13 It is a mullite (mullite) composite oxide. Al particles and Si particles are mixed in a weight ratio of 74.2:25.8, and the powder obtained after mixing is used as a mixture of inorganic compound particles. This mixture of inorganic compound fine particles was mixed with 30 parts by weight of alumina powder (per 100 parts by weight), and fired at 1600°C to obtain a ceramic (sample 22). Its properties including permittivity and thermal conductivity and thermal conductivity are shown in Table 4.

[0057] Dimensional change rate

(%)

Porosity (%)

Dielectric coefficient

(W / m·K)

Sample 22

-0.1

8

7.5

15

Comparative Sample 1

0.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com