Preparation method of collagen/chitosan porous scaffold for tissue engineering

A tissue engineering and porous scaffold technology is applied in the field of preparation of collagen/chitosan porous scaffolds for tissue engineering. and degradability, promoting in vitro construction or in vivo regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The effect of chitosan content on the microstructure of bovine tendon collagen / chitosan porous scaffold

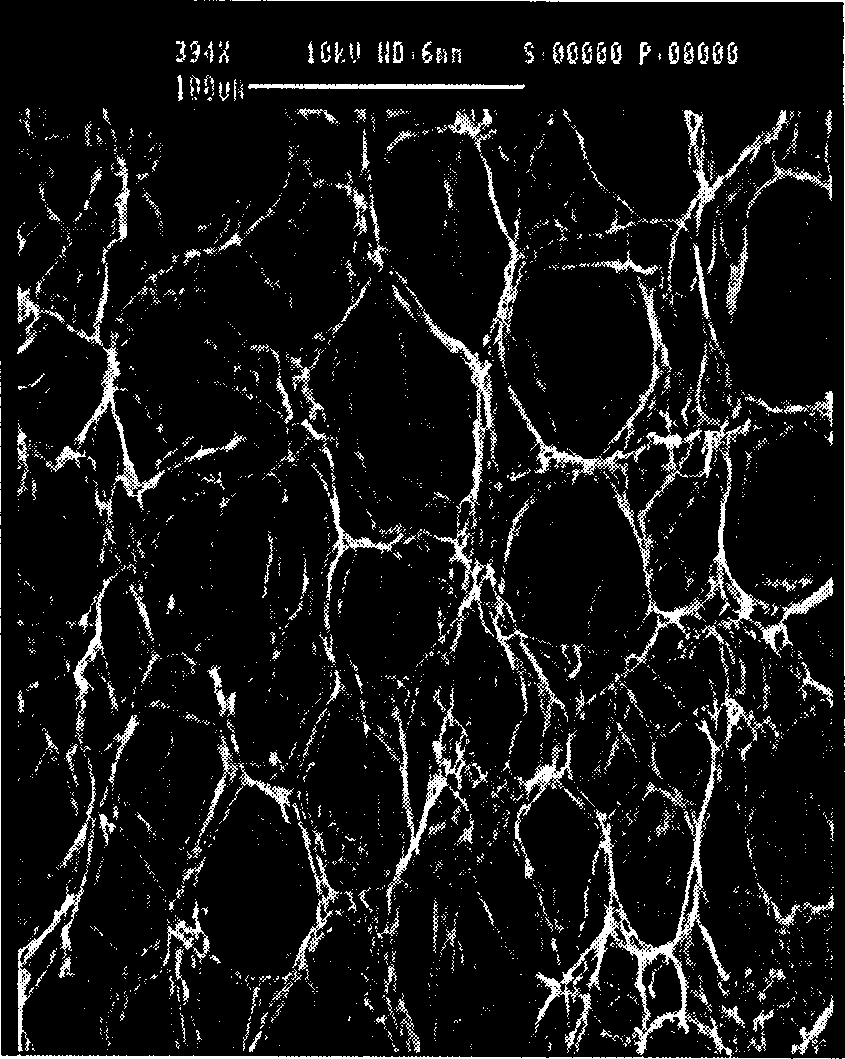

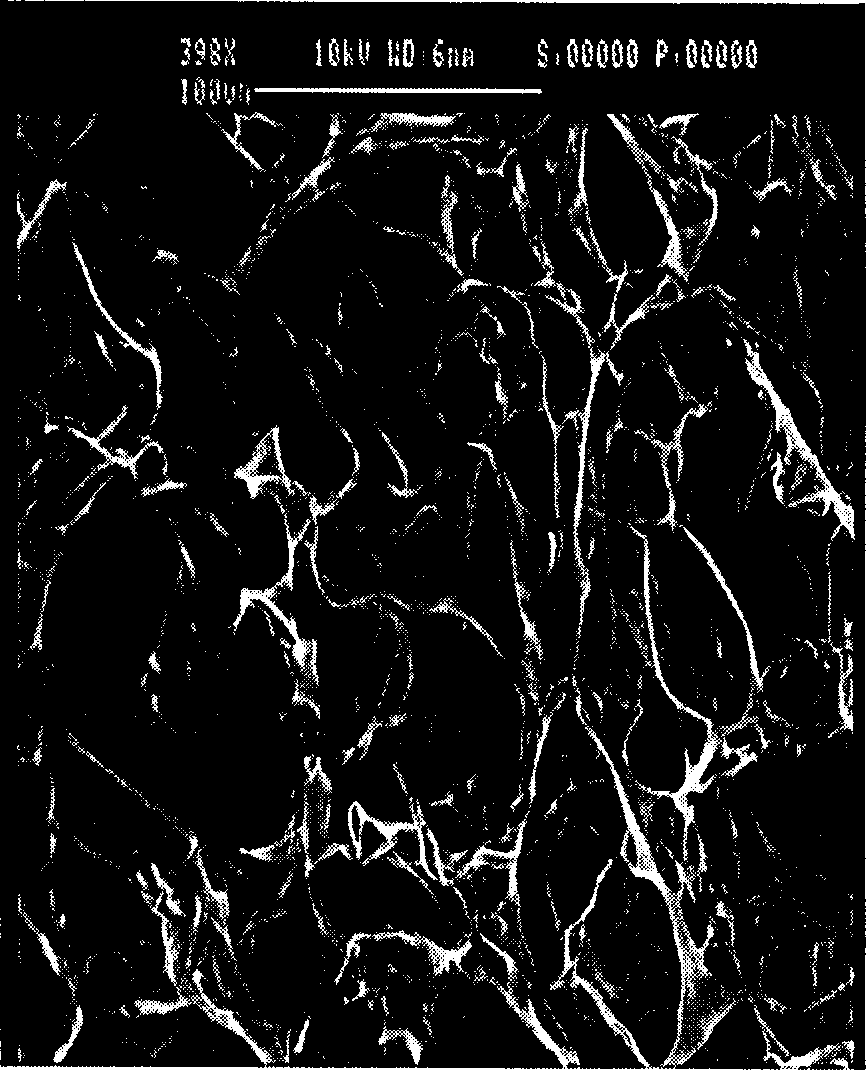

[0028] The collagen of bovine tendon was extracted from bovine tendon by enzymatic hydrolysis and acid extraction. Prepare respectively the collagen solution that concentration is 0.5% and the chitosan solution that concentration is 0.5% with acetic acid solution, then chitosan solution and collagen solution are uniformly blended and obtain chitosan content to be (by weight) 10%, 20% respectively. %, 30%, 50% collagen / chitosan mixed solution. Freeze at -20°C for 1 hour, and after freeze-drying, porous scaffolds with different pore sizes and shapes can be prepared, see Figure 1a , Figure 1b . Figure 1a , Figure 1b These are scanning electron microscope (SEM) pictures of collagen / chitosan scaffolds with chitosan content of 10% and 50%, respectively.

Embodiment 2

[0029] Embodiment 2: the impact of freezing temperature on the microstructure of bovine tendon collagen / chitosan porous scaffold

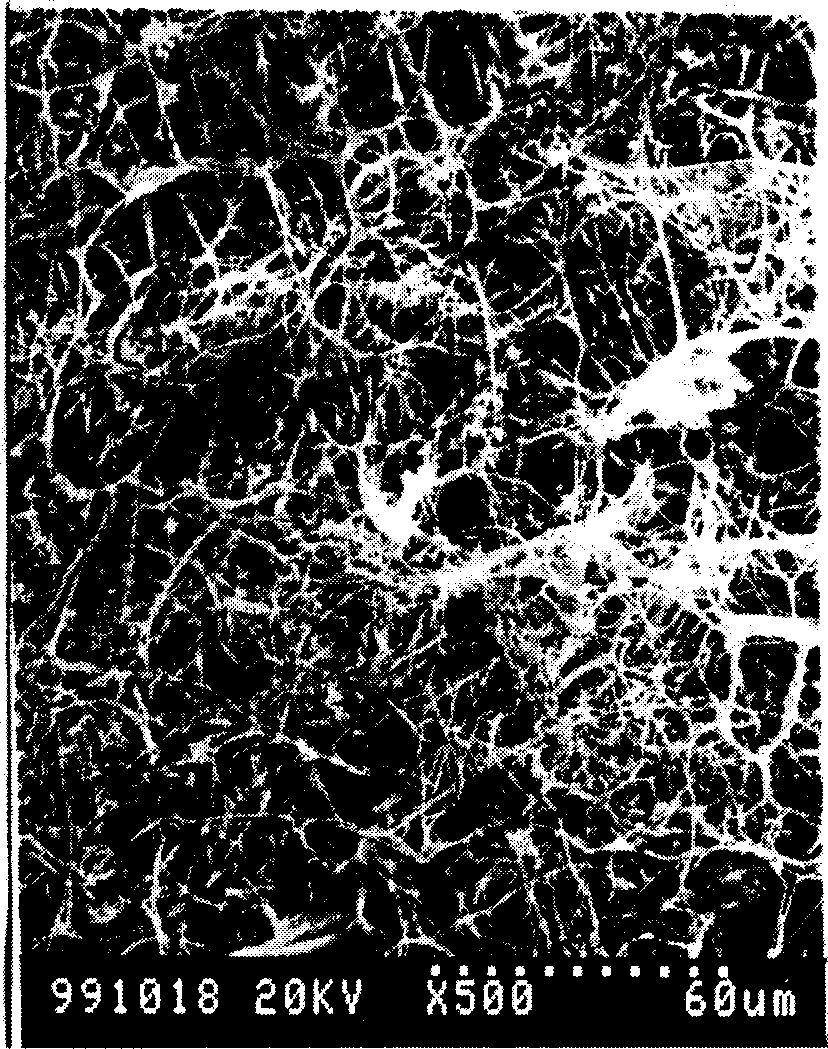

[0030] The collagen of bovine tendon was extracted from bovine tendon by enzymatic hydrolysis and acid extraction. With the acetic acid solution of 0.5M, preparation concentration is respectively the collagen solution of 0.5% and the chitosan solution of 0.5%, then the chitosan solution and the collagen solution are uniformly blended to obtain chitosan content and be (by weight) 10% collagen / Chitosan mixed solution. Then freeze at -50°C and -20°C for 1 hour respectively, and porous scaffolds with different pore sizes can be prepared after freeze-drying, see Figure 2a , Figure 2b . Figure 2a , Figure 2b SEM photos of porous scaffolds prepared by freezing at -50°C and -20°C, respectively.

Embodiment 3

[0031] Embodiment 3: the crosslinking of bovine tendon collagen / chitosan porous scaffold

[0032] The collagen of bovine tendon was extracted from bovine tendon by enzymatic hydrolysis and acid extraction. A 0.5% acetic acid solution was used to prepare a 0.5% collagen solution and a 0.5% chitosan solution, and then the chitosan solution and the collagen solution were uniformly mixed to obtain a chitosan content of 10% (by weight). collagen / chitosan mixed solution. Using the freeze-lyophilization method, freeze at -20°C for 1 hour, and then freeze-dry in a freeze dryer for 24 hours. The freeze-dried collagen / chitosan scaffold was vacuum dry-heated and cross-linked in a vacuum oven at 105° C. for 24 hours to obtain a dry-heat-crosslinked bovine tendon collagen / chitosan porous scaffold. The bovine tendon collagen / chitosan porous scaffold obtained through vacuum dry heat crosslinking was soaked in 100ml of 0.5M acetic acid solution for 1 hour, and then crosslinked with 0.05% to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com