Melt reduction iron-smelting dimethyl ether production and power generation combined production method and installation

A dimethyl ether and combined technology, which is applied in the fields of smelting reduction ironmaking, dimethyl ether production and utilization of waste heat for power generation, can solve problems such as failure to propose specific solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Three batches of tests were carried out by adopting the co-production method and device in which the smelting reduction ironmaking, dimethyl ether production and power generation are combined.

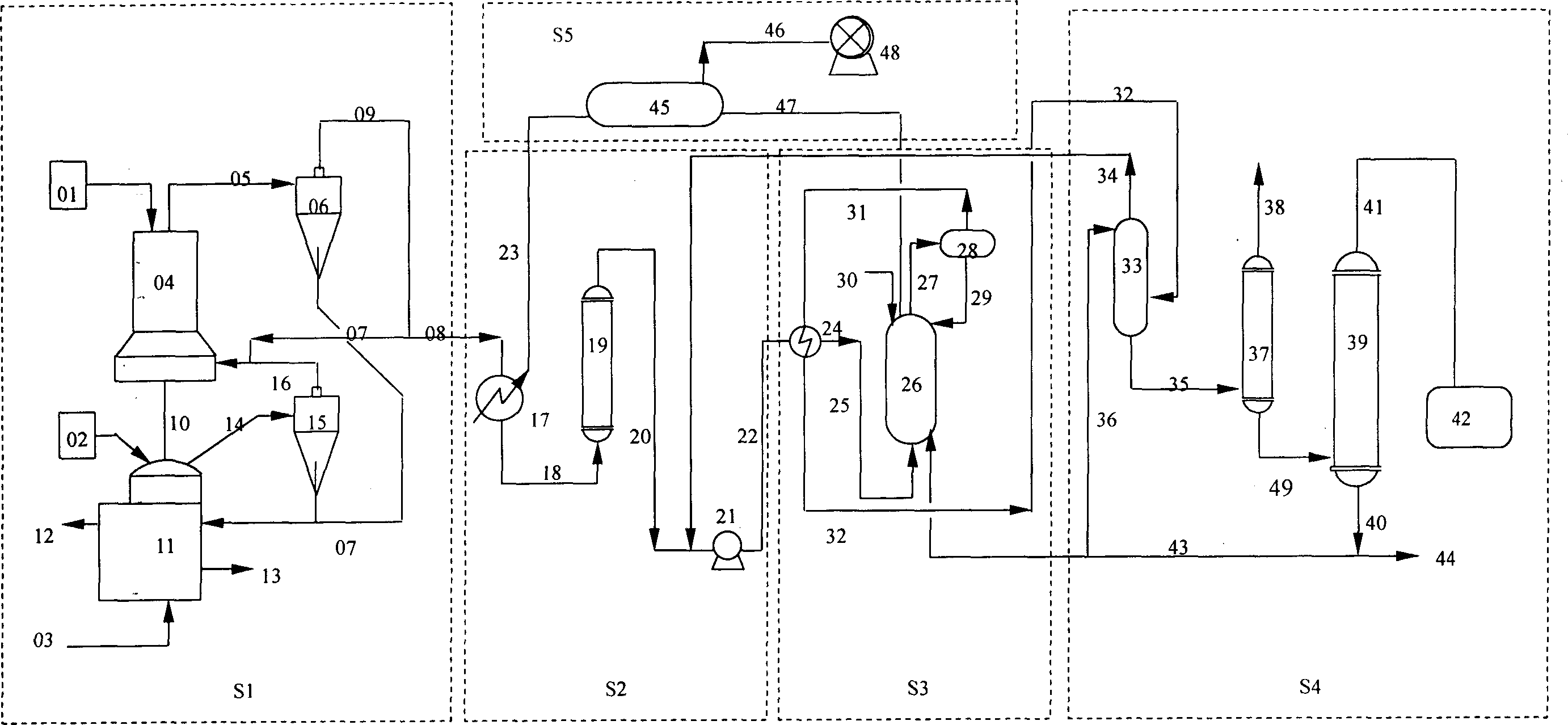

[0068] Firstly, the ore, flux, coal and other raw materials and oxygen are sent to the smelting reduction device according to a certain proportion from the silos 01 and 02, and the oxygen delivery pipe 03 respectively, and the molten iron is discharged from the molten iron outlet 13. At the same time, a large amount of gas is produced. The gas composition, gas generation and iron production are shown in Table 1. The produced coal gas is dedusted by dedusters 06 and 15, and after heat exchange by heat exchanger 17 and dedusting and desulfurization by synthesis gas purification tower 19, it is compressed by compressor 21 to make it have a certain pressure from the dimethyl ether synthesis unit S3. The bottom of the slurry bed reactor 26 enters, and the catalyst and the inert solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com