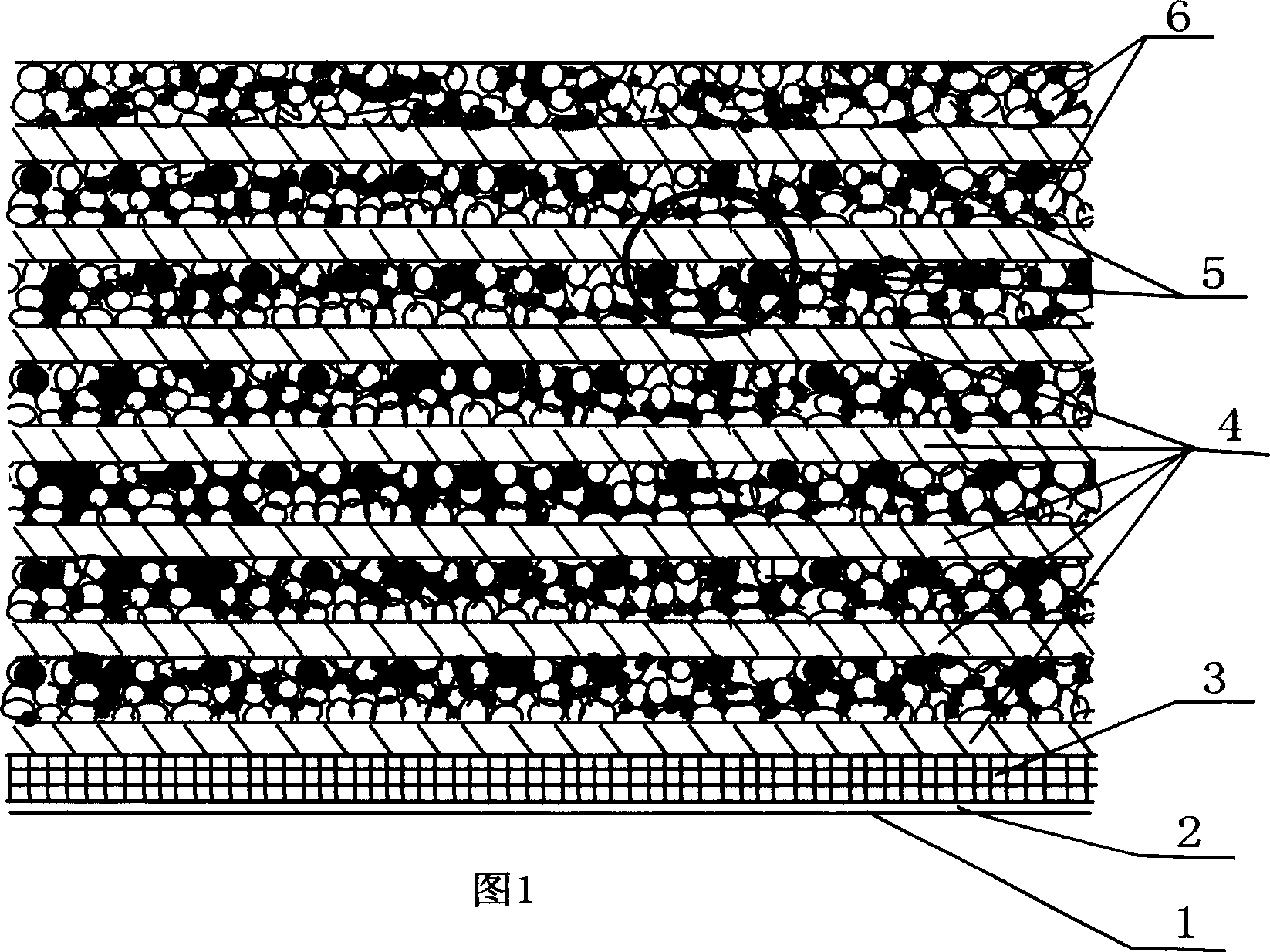

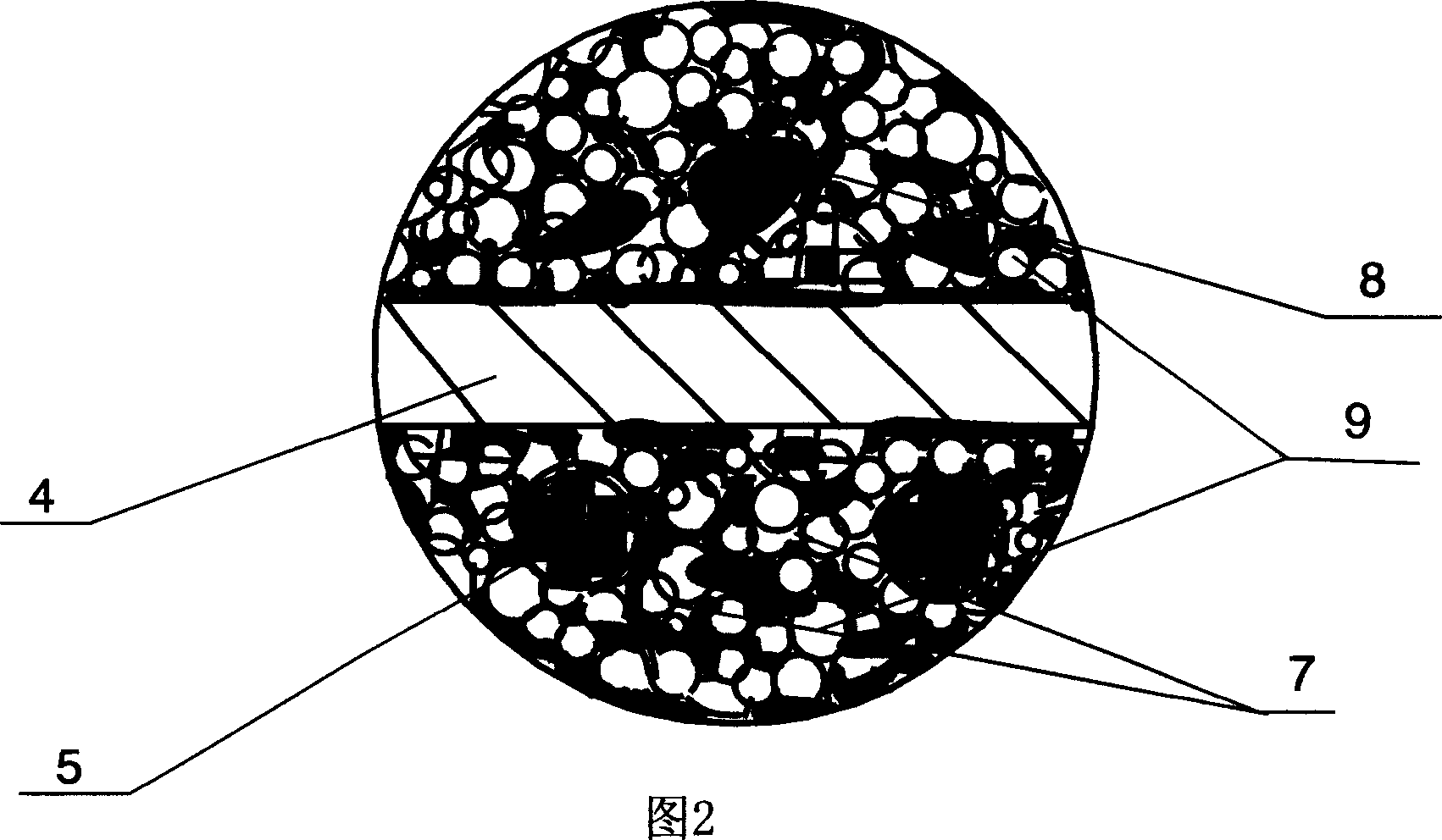

Composite plate with reflecting, insulating, vibration damping and noise reducing functions and its making technology

A composite reflection, vibration reduction and noise reduction technology, applied in the direction of layered products, chemical instruments and methods, metal layered products, etc., can solve the problems of poor strength insulation materials and infrared heat radiation transparency, and increase the internal effective space. , The effect of reducing the thickness and improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The composite reflective thermal insulation, damping, vibration and noise reduction board and its manufacturing process of the present invention have passed industrial production tests.

[0016] Baotou Iron and Steel (Group) Co., Ltd. Steel Plant 90 tons of molten steel tank, tundish

[0017] From October 2001 to the present, 27 molten steel tanks have been installed with 5 mm thick composite reflective heat insulation, damping, vibration and noise reduction panels. After testing, the results showed that the temperature of the outer wall of the molten steel tank dropped by 42°C, the temperature drop rate of the molten steel dropped by 0.82°C / min, the electrode radiation noise was reduced by 11dB during smelting in the LF furnace, and the service life was as high as 18 tanks. There is 1 room bag. After testing, the results showed that the temperature of the outer wall of the tundish dropped by 83°C and the temperature of the molten steel increased by 12°C.

[0018] Jia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com