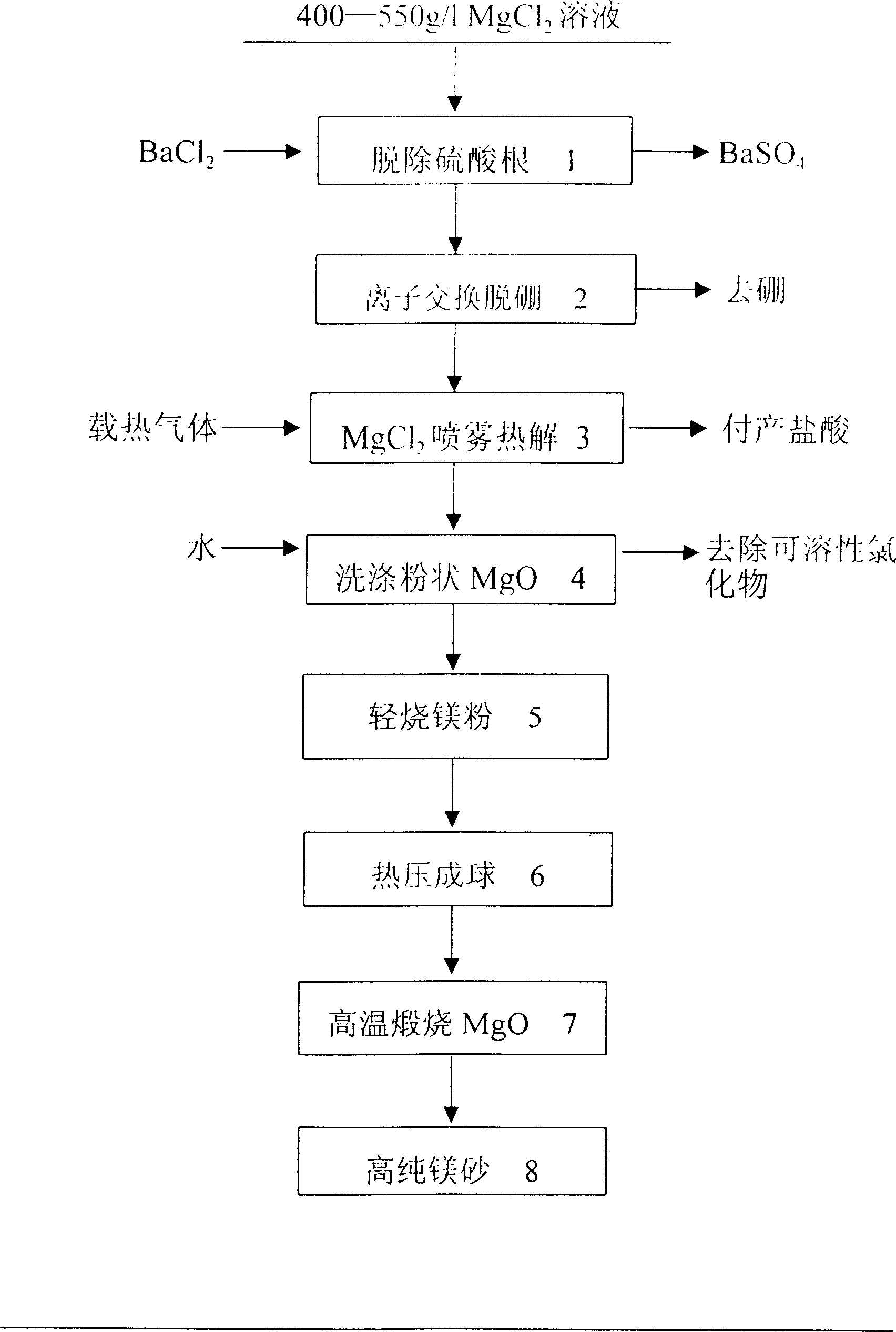

Technology for preparing high purity magnesia by high concentration magnesium oxide solution

A technology of magnesium chloride solution and high-purity magnesia, which is applied in the field of refractory materials, can solve the problems of high heat energy consumption, long process, pollution, etc., and achieve the effect of improving refining technology and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0048] The removal of SO of example 1 magnesium chloride solution 4 =

[0049] 450g / L of MgCl 2 Solution 1000ml, add 20g / l BaCl 2 solution until no more BaSO 4 until precipitation. Filter to remove filter cake BaSO 4 Precipitate, that is obtained by removing SO 4 = Refined MgCl 2 solution, its SO 4 = content below 10 -6 g / l.

example 2

[0050] The boron removal of example 2 magnesium chloride solution

[0051] In the ion-exchange column, a commercially available anion-exchange resin selectively absorbing boron is loaded. The exchange column is 1500mm high, and the column diameter is 70mm, consisting of three stages. Adjust MgCl 2 Solution pH=10, then let boron-containing MgCl 2 (Containing about 12-15ppm boron) solution flows through the exchange column. MgCl obtained after deboronation by exchange column 2 B in solution 2 o 5 The content is less than 0.5ppm.

example 3

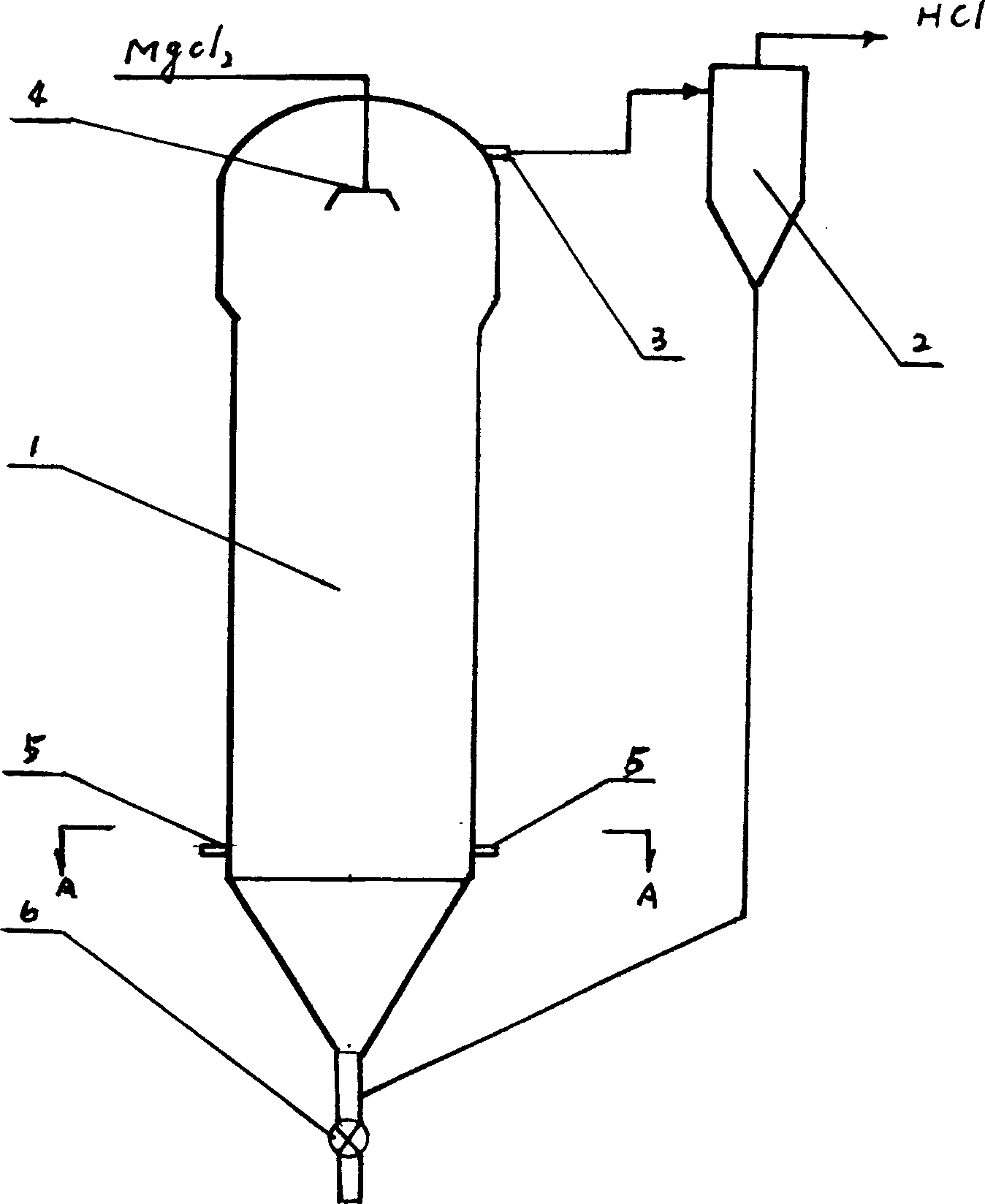

[0053] The concentration is 450g / l has removed SO 4 = and deboronated refined MgCl 2 The solution is sprayed into the hydrolysis reactor from the nozzle, and reacted at 850-800°C for 5 minutes to obtain powdery magnesium oxide powder, which is washed with hot water at 90°C to remove soluble chloride, and the filtrate is filtered and discarded. Baking in a high temperature furnace at 850-900°C for 60 minutes, and then hot pressing into pellets under a pressure of 320MPa. Put it into a high-temperature furnace at 1800°C for calcination for 60 minutes, and obtain high-purity sintered magnesia after cooling. MgO>98%, bulk density>3.4g / cm 3 , crystal particle size>80μm, B 2 o 3 <0.003%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

| Grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com