Polyglycol block modified polyhexanolactone and its preparing method

A kind of polyethylene glycol, polycaprolactone technology, applied in the field of polycaprolactone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

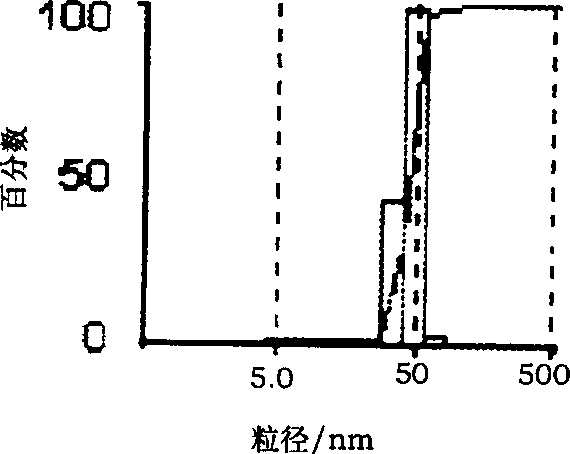

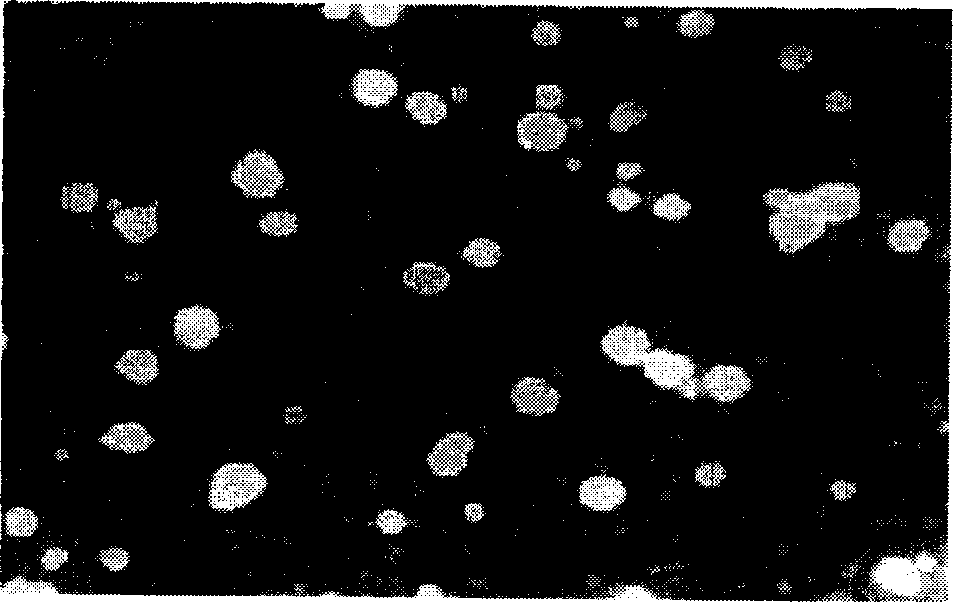

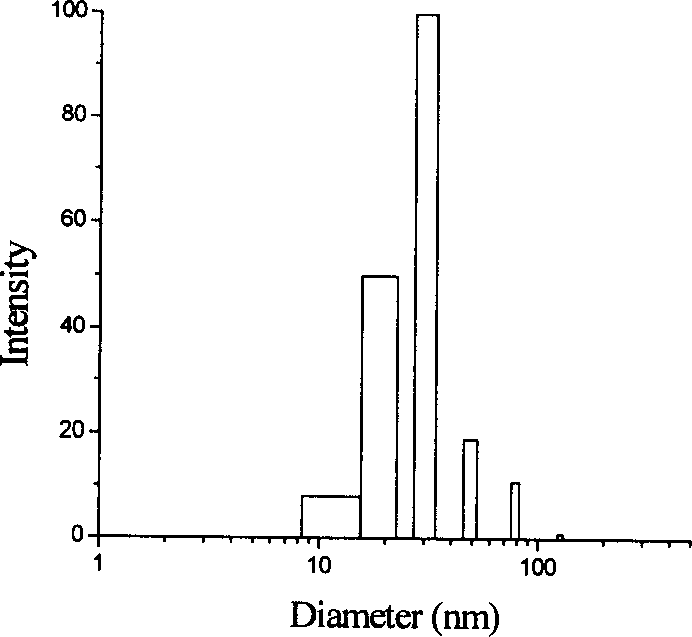

[0027] Add 10g of bishydroxy end group PCL with a relative molecular weight of 2000 and 10-20mL of ethyl acetate into a round-bottomed flask, heat to dissolve and then cool down to 40°C. The feed ratio (molar ratio) of toluene diisocyanate / PCL is 2-2.2 Add toluene diisocyanate and 3-5 mL of ethyl acetate, slowly raise the temperature to 70-90°C and react for 2-5 hours, then add PEG with a relative molecular weight of 2000 and ethyl acetate 10 which are equimolar or slightly excess to the remaining isocyanate groups ~20mL, continue to react for 2~5h, then add the resulting block copolymer solution to 10~30 parts of ether at 4~10°C for precipitation, centrifugal separation or vacuum filtration to obtain polyethylene glycol block modified Polycaprolactone amphiphilic triblock copolymer. The particle size distribution of the micelles (the concentration of the block copolymer is 0.5%) formed by self-assembly of this polyethylene glycol block-modified polycaprolactone in water is as...

Embodiment 2

[0029]The device and operation are the same as in Example 1. Add 10 g of bishydroxy PCL with a relative molecular weight of 4000 and 10-20 mL of ethyl acetate into a round-bottomed flask, heat and dissolve, then cool down to 40 ° C, and use toluene diisocyanate / PCL as 2-2.2 Feed ratio (molar ratio) Add 3-5mL of toluene diisocyanate and ethyl acetate, slowly raise the temperature to 70-90°C and react for 2-5h, then add polystyrene with a relative molecular weight of 2000 that is equimolar or slightly excess with the remaining isocyanate groups. Ethylene glycol monomethyl ether and ethyl acetate 10 ~ 20mL, continue to react for 2 ~ 5h, then add the resulting block copolymer solution to 10 ~ 30 parts of 4 ~ 10 ℃ ether for precipitation, centrifugal separation or decompression Suction filtration obtains poly(ethylene glycol) block modified polycaprolactone amphiphilic tri-block copolymer.

Embodiment 3

[0031] The device and operation are the same as in Example 1. Add 10 g of dihydroxy PCL with a relative molecular weight of 2000 and 10 to 20 mL of ethyl acetate into a round bottom flask, heat to dissolve and then cool down to 40 ° C. Feeding ratio (molar ratio) Add 3-5mL of toluene diisocyanate and ethyl acetate, slowly raise the temperature to 70-90°C and react for 2-5h, and then add hydroxy End group ethylene oxide and propylene oxide block copolymer and ethyl acetate 10-20mL, continue to react for 2-5h, then add the resulting block copolymer solution to 10-30 parts of ether at 4-10°C The polycaprolactone amphiphilic three-block copolymer of poly(ethylene glycol) block modification is obtained by precipitation in medium, centrifugation or suction filtration under reduced pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com