Integzal type oxidation catalyst of sulfur dioxide possessing regular channels and its preparing method

A technology for oxidation catalysts and sulfur dioxide, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Single arrangement, shortened service life of catalysts, etc., to achieve the effect of facilitating mass production, strong anti-dust and anti-blocking ability, and reducing fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

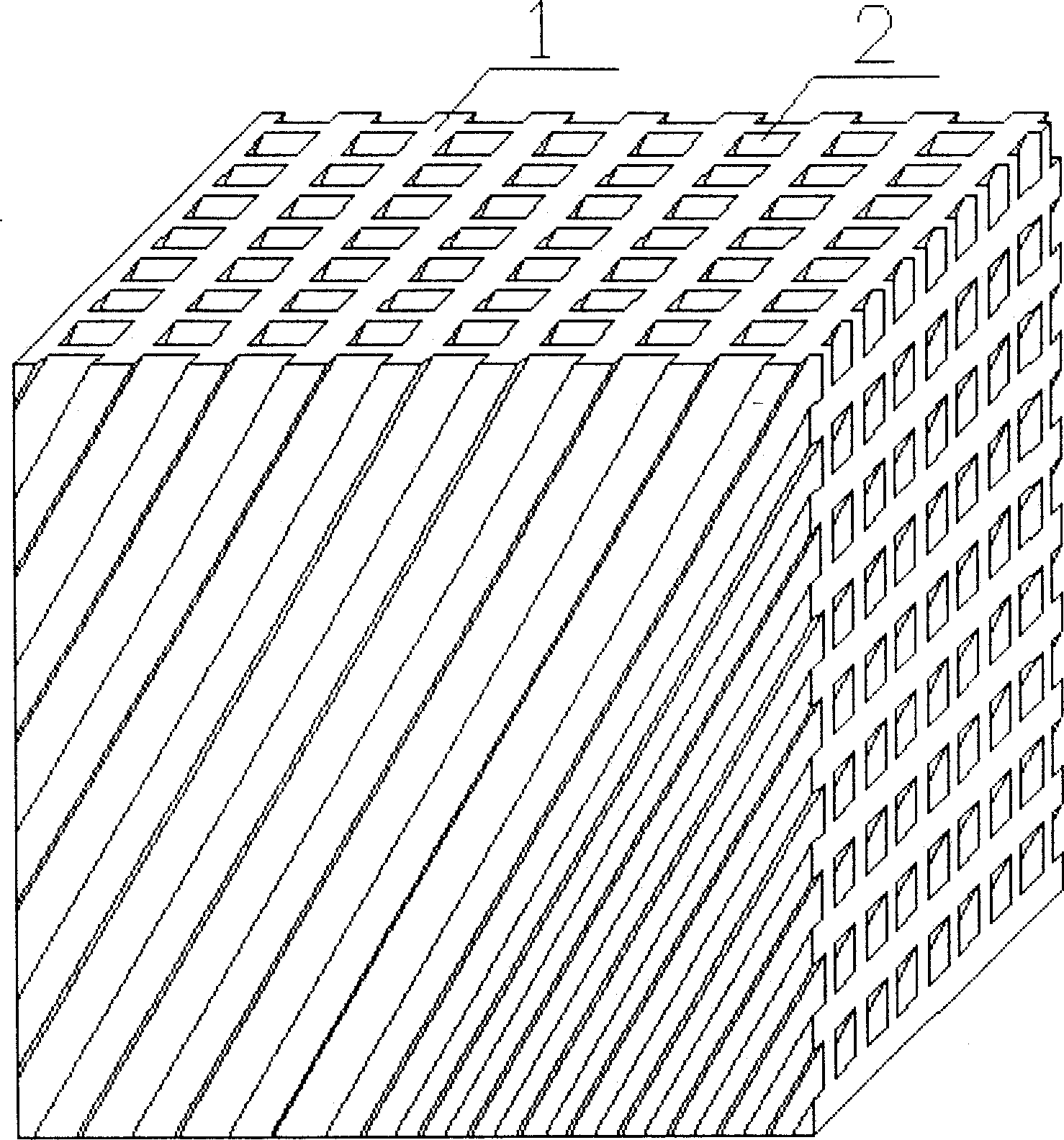

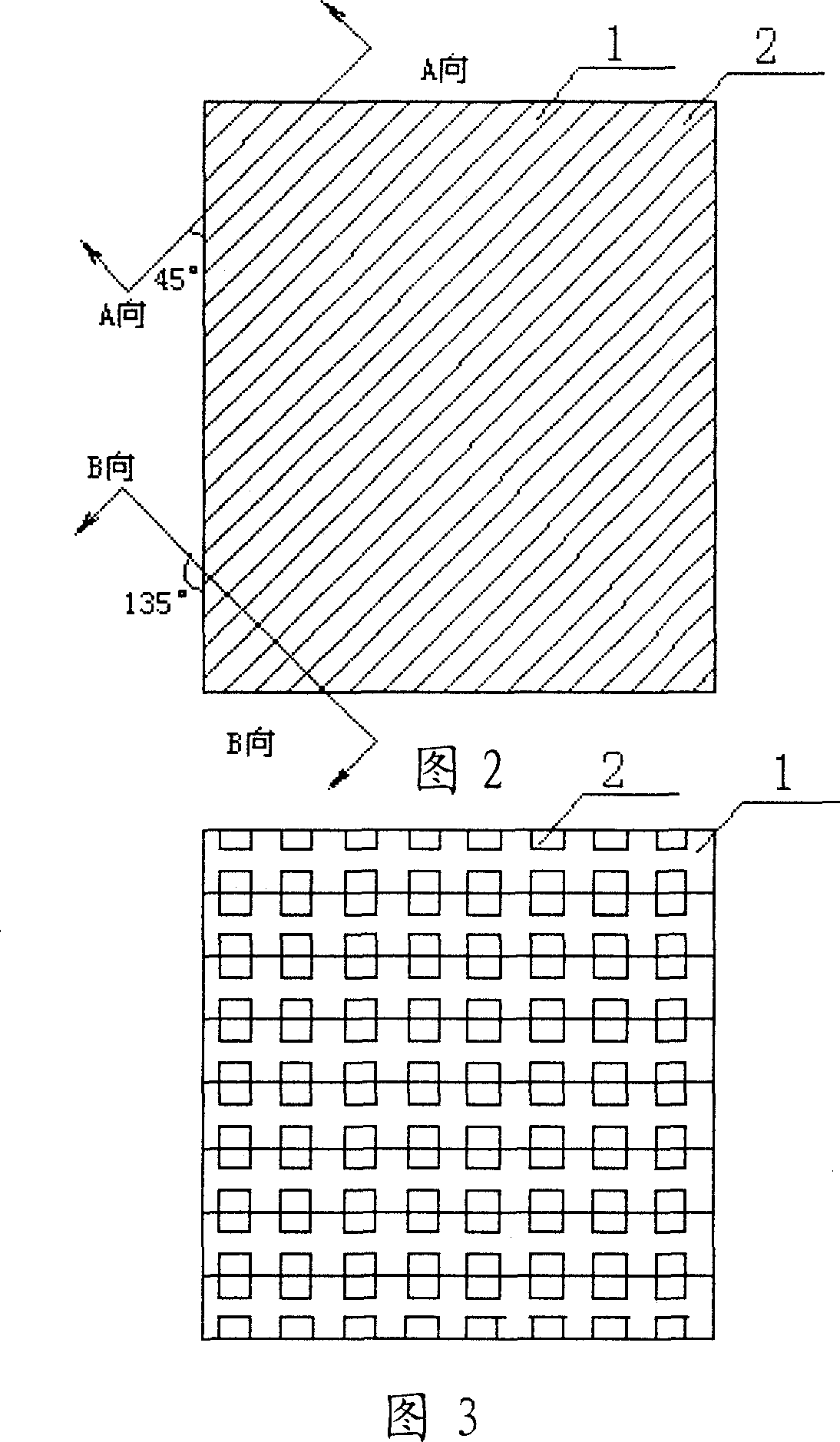

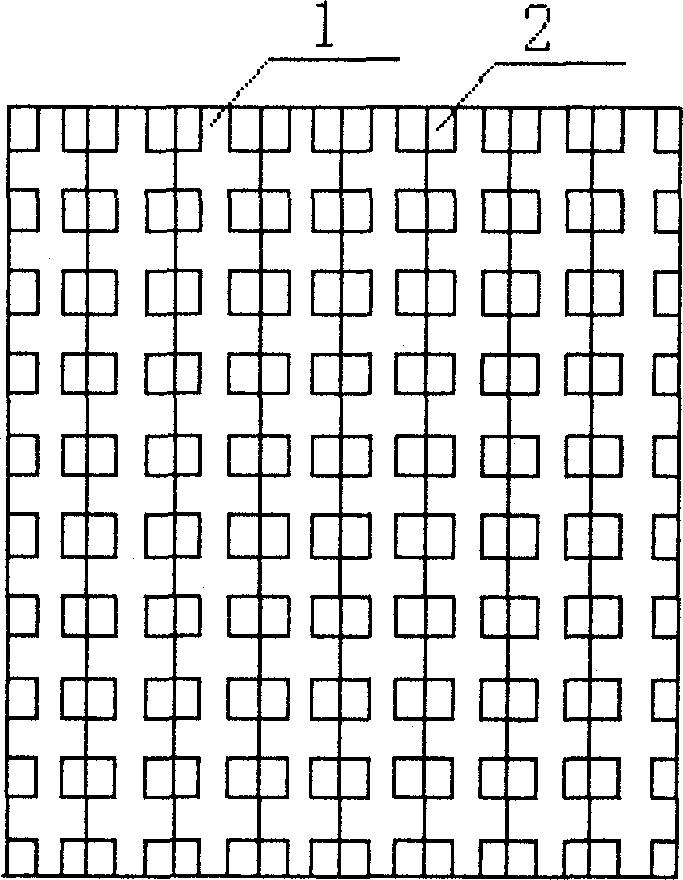

[0052] The shape and structure of the sulfur dioxide oxidation catalyst prepared in this example are as follows: figure 1 As shown in Figure 6, the body 1 is a cube, and the fluid channels 2 in the body are distributed in layers. The fluid channels in each layer are composed of two groups of rectangular grooves arranged in parallel and with an angle of 90° between each other. One group of rectangular grooves The included angle between the groove and the axis of the reaction bed is 45°, so that the fluid channel of each layer is a rectangular groove cross network structure.

[0053] The raw material components for preparing sulfur dioxide oxidation catalyst are as follows:

[0054] Diatomaceous earth 1000g 10mm glass fiber 62.5g

[0055] V2 o 5 100g P 2 o 5 62.5g

[0056] KOH 169g Graphite 25g

[0057] Na 2 SO 4 100g sulfur 25g

[0058] The process steps of preparing sulfur dioxide oxidation catalyst are as follows:

[0059] (1...

Embodiment 2

[0073] The shape and structure of the sulfur dioxide oxidation catalyst prepared in this example are the same as those in Example 1.

[0074] The raw material components for preparing sulfur dioxide oxidation catalyst are as follows:

[0075] Diatomaceous earth 1000g 10mm glass fiber 100g

[0076] V 2 o 5 100g P 2 o 5 100g

[0077] KOH 169g Graphite 50g

[0078] Na 2 SO 4 100g sulfur 50g

[0079] Lignosulfonate 25g

[0080] The process steps of preparing sulfur dioxide oxidation catalyst are as follows:

[0081] (1) Slurry preparation

[0082] Same as Example 1.

[0083] (2) Mold combination

[0084] Same as Example 1.

[0085] (3) Molding and forming

[0086] Using the pressure grouting process, apply 10MPa pressure to the prepared slurry and inject it into the mold and vibrate. The vibration frequency is 120 / min. The vibration time is limited to the absence of air bubbles in the slurry. After the grouting is completed, put the...

Embodiment 3

[0092] The shape and structure of the sulfur dioxide oxidation catalyst prepared in this example is different from Example 1 in that the fluid channel is composed of two sets of trapezoidal grooves arranged in parallel with each other and the angle between them is 90°, wherein one set of trapezoidal grooves and the reaction The included angle of the bed axis is 45°, so that the fluid channel of each layer is a trapezoidal groove cross network structure.

[0093] The raw material components for preparing sulfur dioxide oxidation catalyst are as follows:

[0094] Diatomaceous earth 800g Kaolin 200g

[0095] 10mm glass fiber 62.5g V 2 o 5 100g

[0096] P 2 o 5 62.5g KOH 169g

[0097] Graphite 50g Sulfur 50g

[0098] Lignosulfonate 25g Methylcellulose 50g

[0099] The process steps of preparing sulfur dioxide oxidation catalyst are as follows:

[0100] (1) Slurry preparation

[0101] Same as Example 1.

[0102] (2) Mold combination

[0103] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com