Electric spark bombardment device for colloidal silver solution

An electric spark and colloidal silver technology, which is applied in the field of colloidal silver solution preparation devices, can solve the problems of high production cost, complicated and expensive equipment manufacturing, etc., and achieve the effects of convenient operation, simple structure and excellent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention is described in further detail:

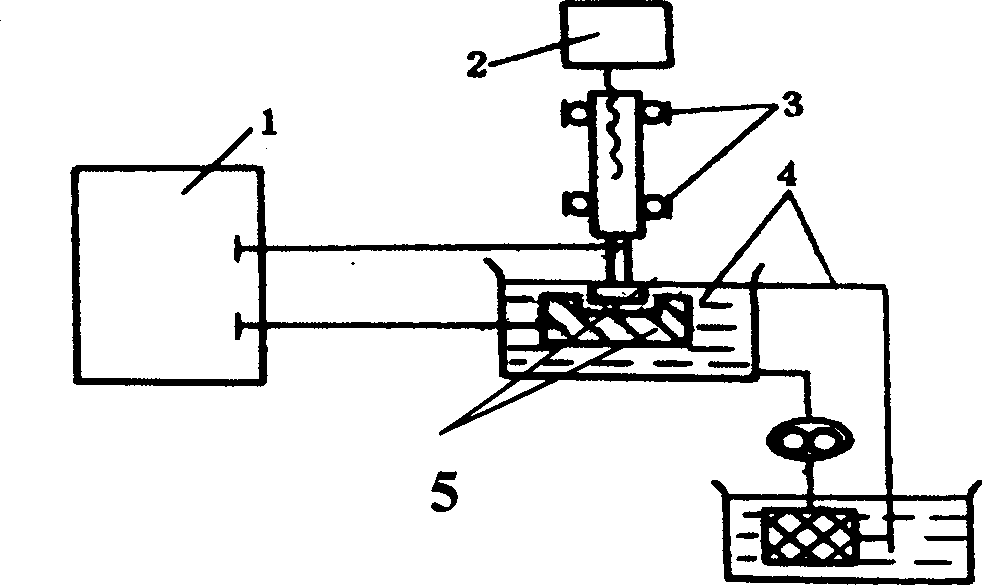

[0039] according to figure 1 , figure 2 , image 3 It can be seen that it is composed of a high-frequency pulse generator 1, a discharge gap automatic regulator 4, a plastic tube 12, and a plastic impeller pump 13. The high-frequency pulse generator 1 is connected to the positive silver electrode 15 and the negative silver electrode 16 through wires 2 and 3. Because the high-frequency pulse power supply 1 and the discharge gap automatic regulator 4 are prior art (so not illustrated). The sawtooth wave generated by the high-frequency pulse generator 1 is applied to both ends of the positive and negative silver electrodes through the wires 2 and 3. The silver electrode clip 8 is connected with the positive silver electrode 15 and the base 5 of the silver electrode plate motion transmission system. The stepping electrode 6 The ball screw 7 is respectively connected w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com