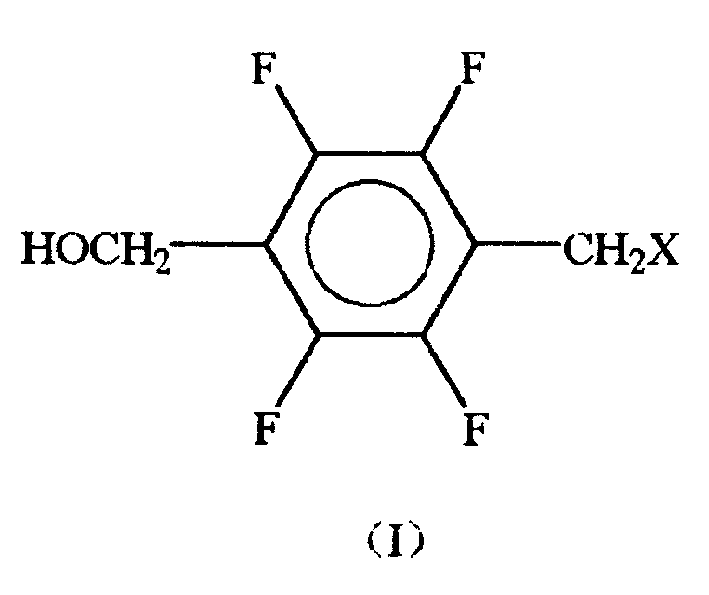

Method for preparing 4-methyl-tetrafluoro-benzil-alcohol

A technology of methyltetrafluorobenzyl alcohol and alkyl, which is applied in the field of preparation of 4-methyltetrafluorobenzyl alcohol, and can solve the problems of low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 26.9g (0.01mol) tetrafluoro-tere-phenylenedimethanol monoacetate, 2.0g 5% palladium charcoal and 250ml acetic acid are placed in the autoclave, pass into hydrogen after replacing the air in the autoclave with nitrogen, control the pressure to be 5 atm, and the temperature is 80 ℃ for about 4 hours. Cool, depressurize, suction filter, concentrate the filtrate under reduced pressure, pour into 500ml of water after a little cooling, stir for a while, suction filter, wash with water, dry, and recrystallize petroleum ether to obtain 18.6g off-white solid, MP60~62℃, yield 88 %.

Embodiment 2

[0017] 22.9g (0.10mol), 4-chloromethyltetrafluorobenzyl alcohol, 16.3g zinc powder (0.25mol) and 100ml 50% ethanol are placed in the reaction flask, heated to 60-65°C, and 18g (0.30 mol) acetic acid, heated to reflux for 2 hours after dripping, filtered while hot, the filtrate was heated to evaporate ethanol, cooled, filtered, washed with water, dried, recrystallized from petroleum ether to obtain 14.8g off-white solid, yield 76%.

Embodiment 3

[0019] 5.0g (0.018mol) of 4-bromomethyltetrafluorobenzyl alcohol and 50ml of methanol were placed in a conical flask, and 2.7g (0.072mol) of sodium borohydride was added in batches under magnetic stirring, and the addition was completed in about 2 hours, and heated to Stir at 50°C for 8 hours, cool, add a small amount of dilute hydrochloric acid dropwise, then add 100ml of water and 100ml of toluene, after stirring, separate the toluene layer, evaporate the solvent, and recrystallize petroleum ether to obtain 2.8g of off-white solid with a yield of 80 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com