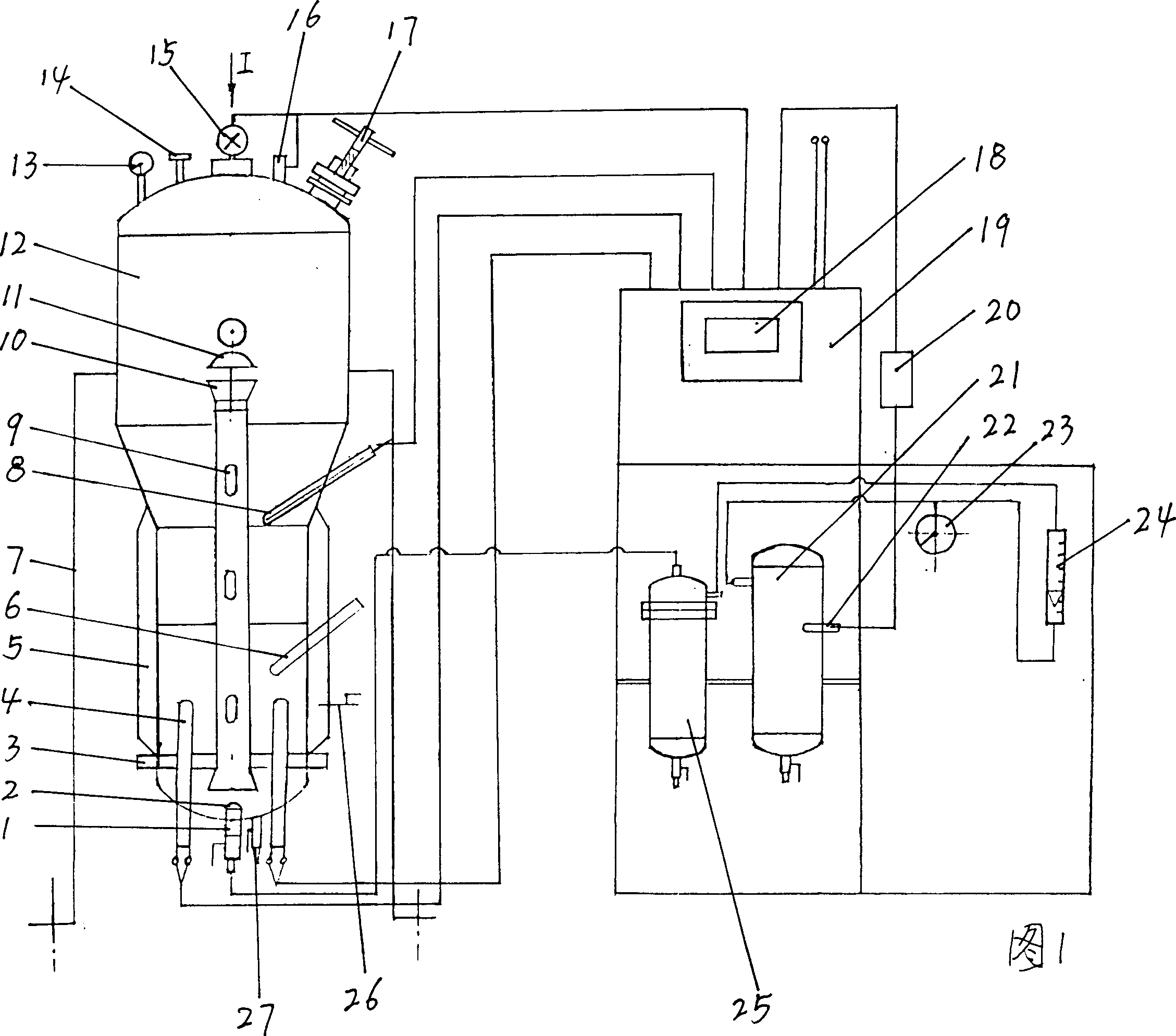

Liquid edible fungus strain producing method and apparatus

A technology of liquid strains and edible fungi, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of high cost, long growth cycle, easy pollution, etc., and achieve easy inoculation , the effect of less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Production process of black fungus and Agaricus bisporus liquid strains

[0065] 1. The formula of liquid bacteria

[0066] 1. Black fungus:

[0067] Potato 10%, brown sugar 1.5%, glucose 1%, wheat bran 4%, peptone 0.2%, KH 2 PO 4 0.2%, MgSO 4 0.1%, VB10mg / l, foam enemy 0.03%, the balance is water, pH value 6.5-7.5.

[0068] 2. Agaricus bisporus:

[0069] Potato 10%, brown sugar 1.5%, glucose 1%, wheat bran 4%, peptone 0.2%, KH 2 PO 4 0.2%, MgSO 4 0.1%, VB 10mg / l, foam enemy 0.03%, yeast extract 0.1%, the balance is water, and the pH value is 7.5.

[0070] Second, the preparation of culture medium

[0071] 1. Potatoes: dig out buds, peel and wash, cut into 0.2-0.4cm strips or slices and cook until crisp but not rotten, then filter with 6-8 layers of gauze to get the filtrate.

[0072] 2. Wheat bran: add water, stir and continue to boil for 20 minutes, then filter with 6-8 layers of gauze to get the filtrate.

[0073] 3. Brown sugar and glucose: di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com