Method of decontaminating sulfur dioxide in smoke using honeycomb ceramic

A technology of honeycomb ceramics and sulfur dioxide, which is applied in the field of sulfur dioxide desulfurization technology, can solve the problems of large equipment, complex technology, and large floor area, and achieve the effects of reducing sulfur dioxide content, good desulfurization effect, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

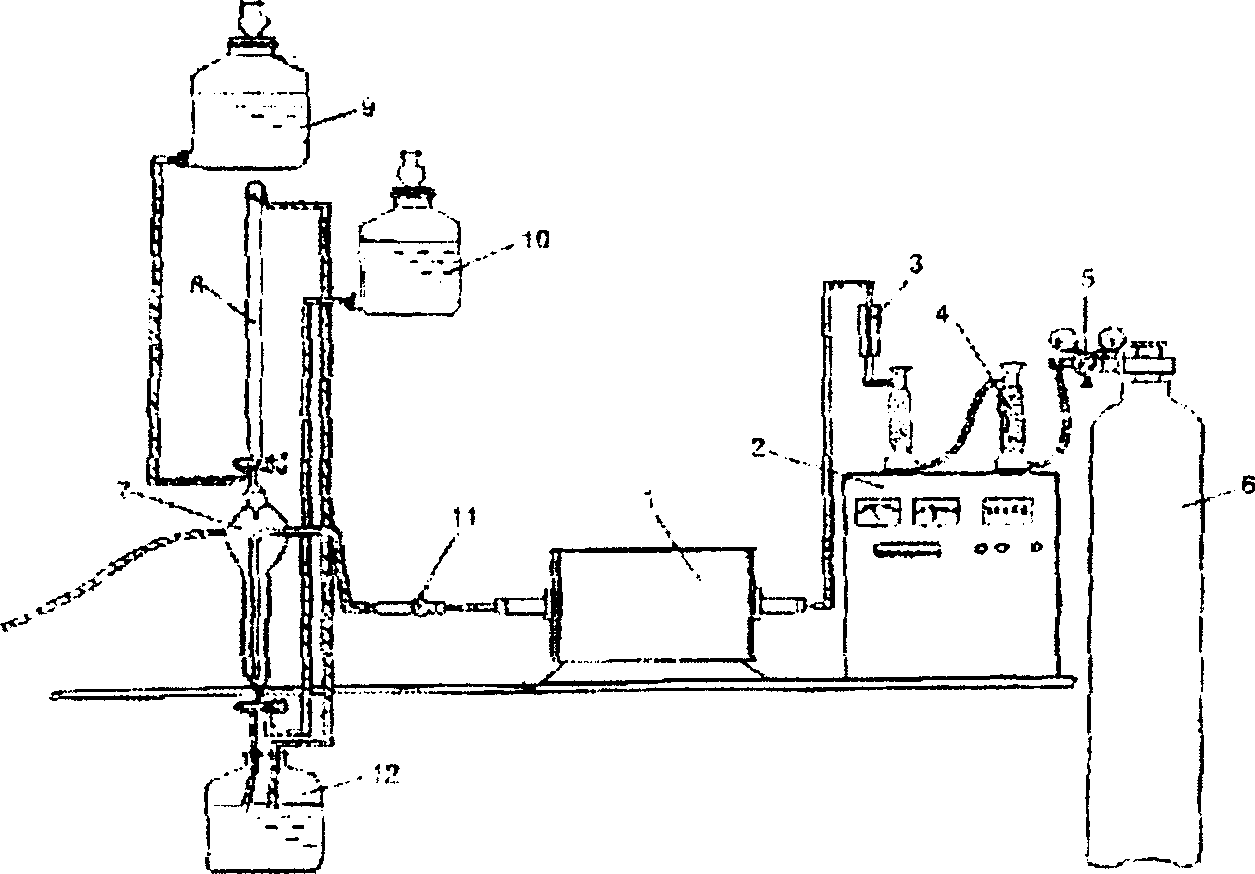

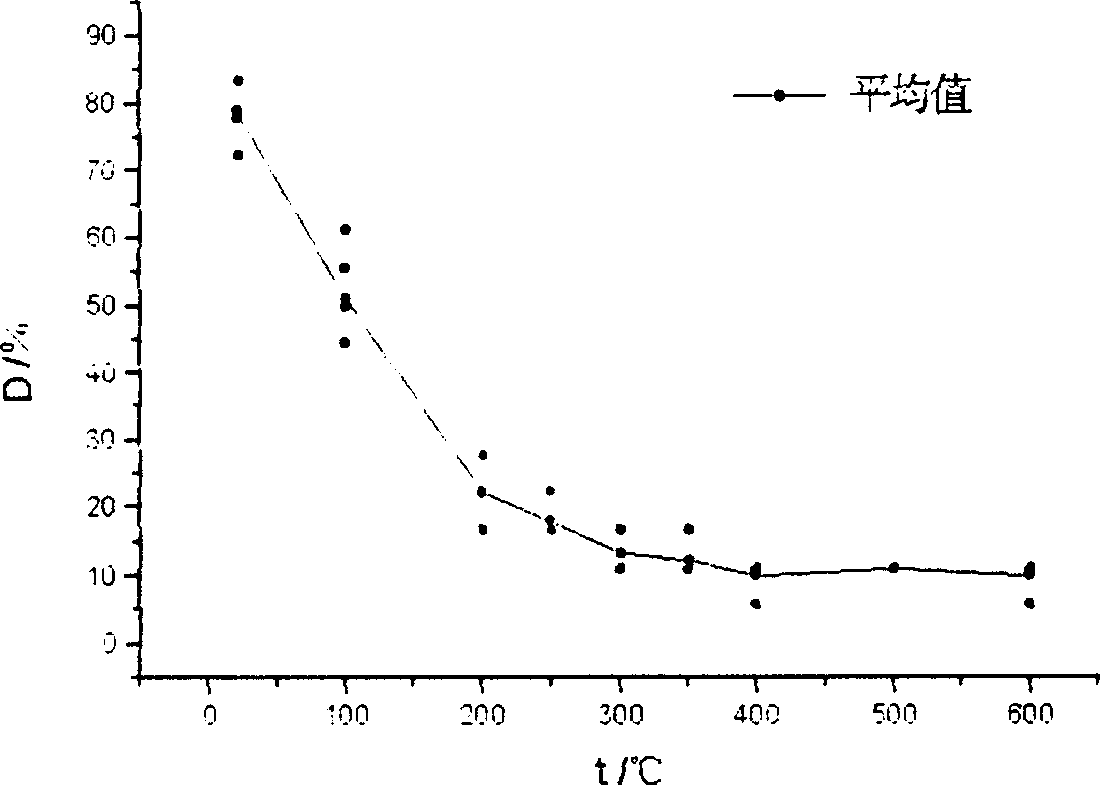

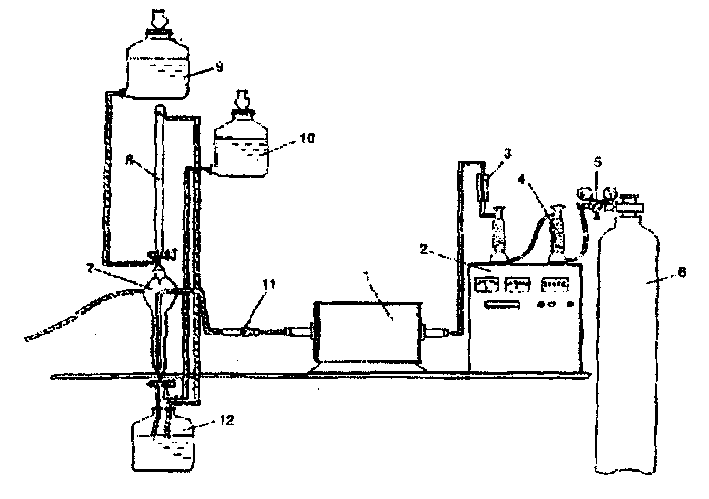

[0020] According to SO in flue gas from a sintering plant of a steel company in Beijing 2 Actual concentration, with air or oxygen and SO 2 Gas prepared as test gas, SO 2 The volume concentration is 4.92×10 -4 , control the ventilation time of the test gas, pass it into the experimental system quantitatively, and then use pure oxygen to drive away the residual sulfur-containing gas in the system), absorb it with the sulfur-fixed absorption liquid in the reactor, and then titrate it with NaOH standard solution , to determine the SO of the test gas 2 true concentration. Grind the honeycomb ceramic bricks with different pore densities into cylinders matching the inner diameter of the furnace tube, immerse them in the lime emulsion to fully absorb the lime emulsion, and then place the honeycomb ceramic bricks soaked in the lime emulsion in the constant temperature zone of the tube furnace . At different temperatures, repeat the above process of feeding test gas and absorbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com