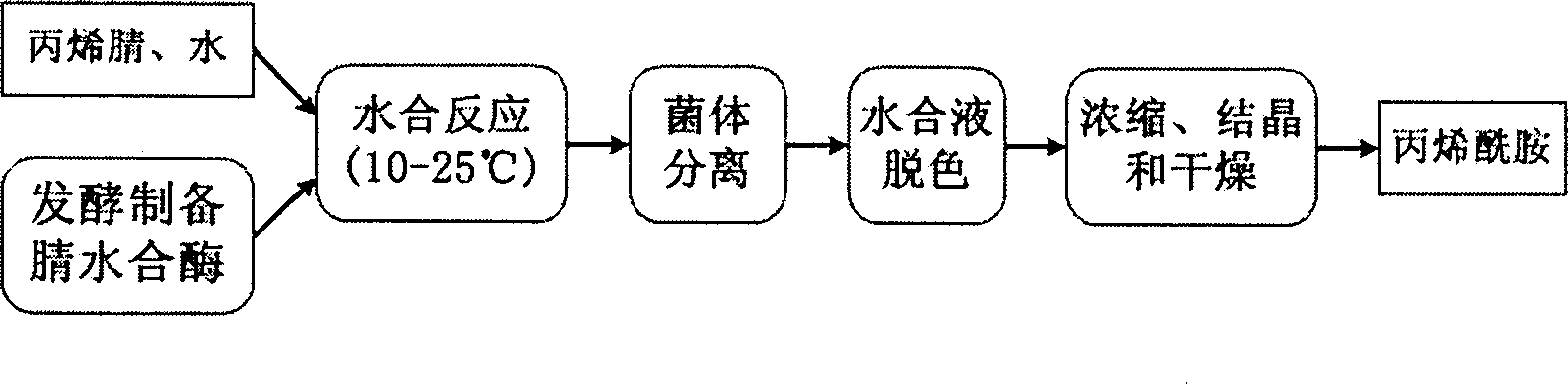

Technique method for preparing hydratase of carbonitrile mitrile by using glucose-CO2+ coupling adding ferment

A technology of nitrile hydratase and process method, applied in the preparation, fermentation, hydrolase and other directions of organic compounds, can solve the problems of inconvenient on-line measurement, abnormal metabolism, difficult control and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

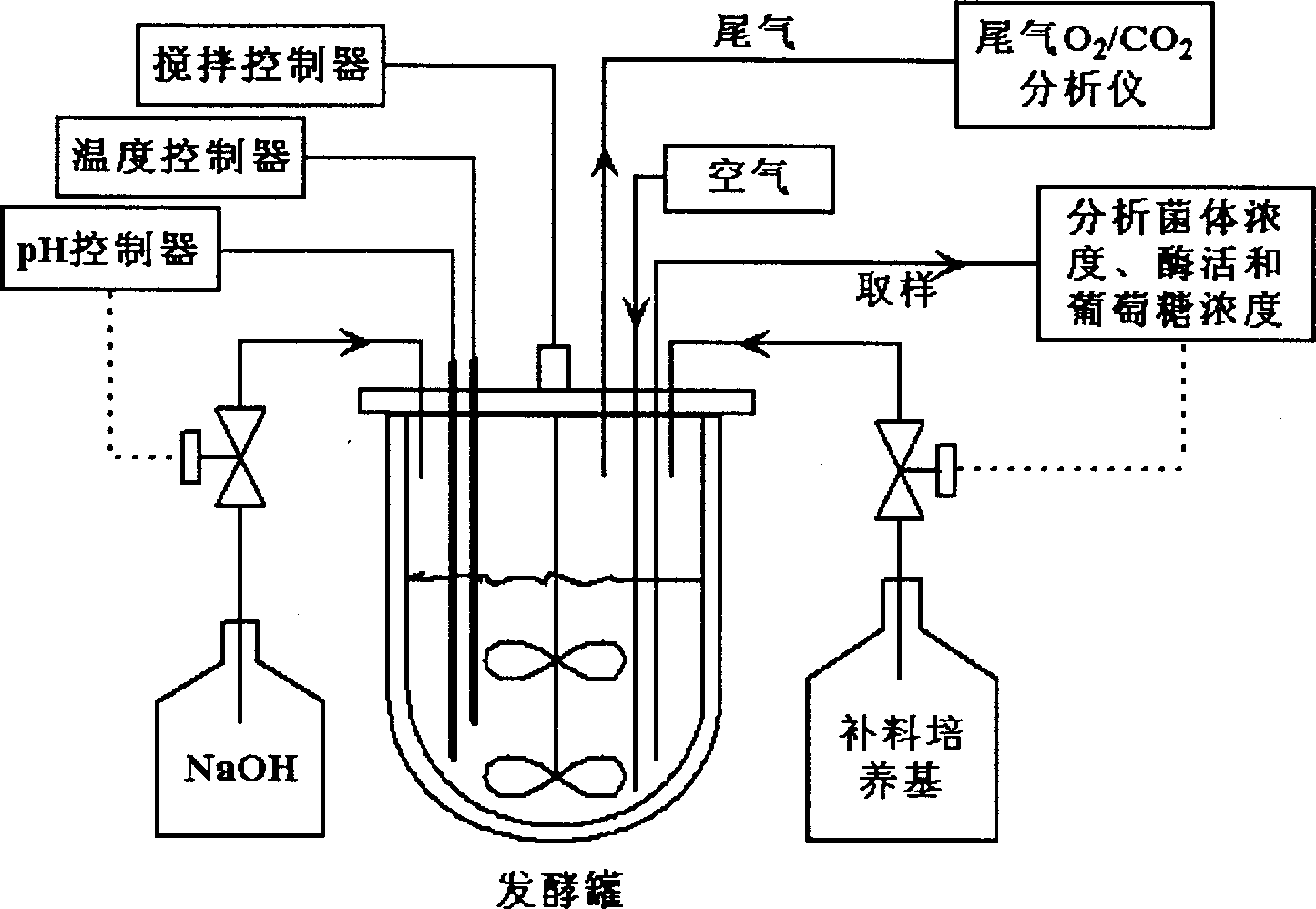

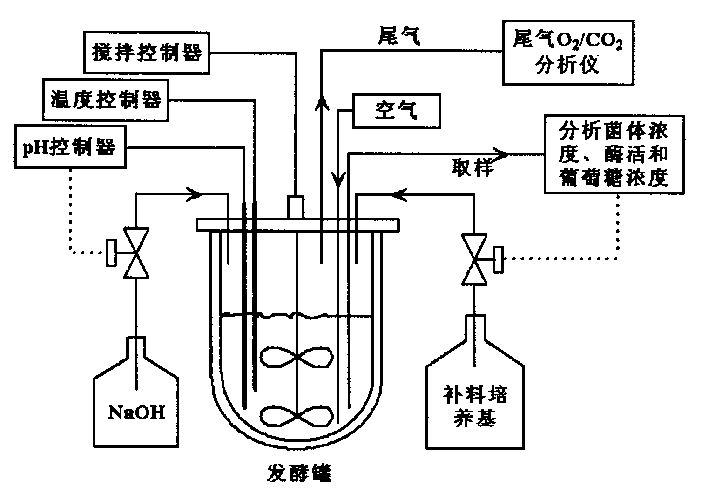

[0014] We investigated glucose consumption and Co 2+ The impact on the enzyme production process, it is found that the maximum sugar consumption rate of glucose in the fermentation process appears in the rapid enzyme production period, and the enzyme production rate reaches the maximum. It is used to produce enzymes and maintain the metabolism of bacteria. From the perspective of changing trends, the enzyme production rate and sugar consumption rate show a high positive correlation at this stage. During the deceleration period of enzyme production, glucose tends to be exhausted, the rate of sugar consumption decreases, and the rate of enzyme production also decreases rapidly, and the trend of change is consistent. If the glucose concentration is regulated in the late stage of rapid enzyme production, so that the enzyme production rate can be maintained at a high level for a longer period of time, the enzyme production process can be further enhanced. On this basis, we develop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com