Technological method and equipment for preparing nitrogen trifluoride gas

A process method, nitrogen trifluoride technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of affecting the continuous operation of production, prone to explosion, complicated operation, etc., to eliminate unsafe hidden dangers, equipment operation safety, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in more detail below with reference to the process flow diagram of the present invention. The present invention can have many specific implementations, and is not limited to the specific implementations described herein.

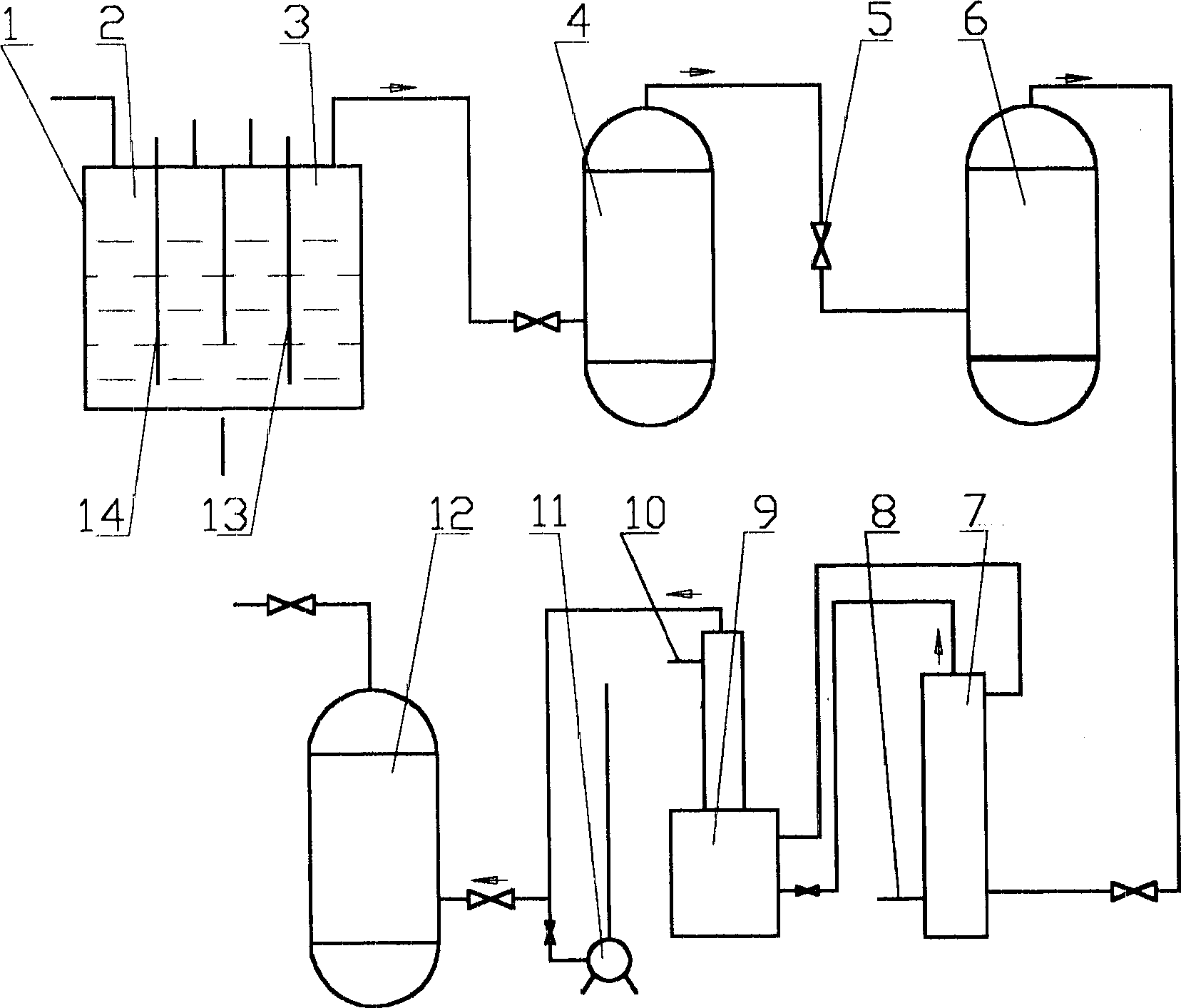

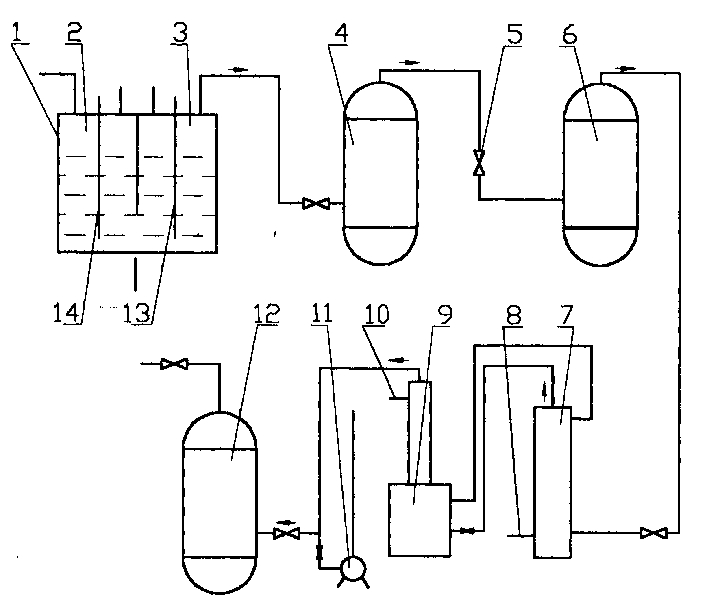

[0029] The equipment of the present invention comprises an electrolytic cell 1, a pressure balance tank 4, a low pressure tank 6, a low-temperature cooling tower 7, an ultra-low temperature cold trap 9, a vacuum pump 11, and crude product NF 3 The gas storage tank 12, the anode area of the electrolytic cell 1 are in sealing communication with the pressure balance tank 4 through the pipeline, the pressure balance tank 4 is in sealing communication with the low-pressure tank 6 through the pipeline and the regulating valve 5, and the low-pressure tank 6 is in sealing communication with the low-temperature cooling tower 7 through the pipeline , the low-temperature cooling tower 7 is in sealed communication with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com