Synthesis of double walled carbon nano-tubes

A technology of double-walled carbon nanotubes and a synthesis method, which is applied in the field of synthesis of double-walled carbon nanotubes, can solve problems such as inappropriate process parameters, no double-walled carbon nanotubes are found, etc., and achieves simple operation, high stability, and improved performance. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

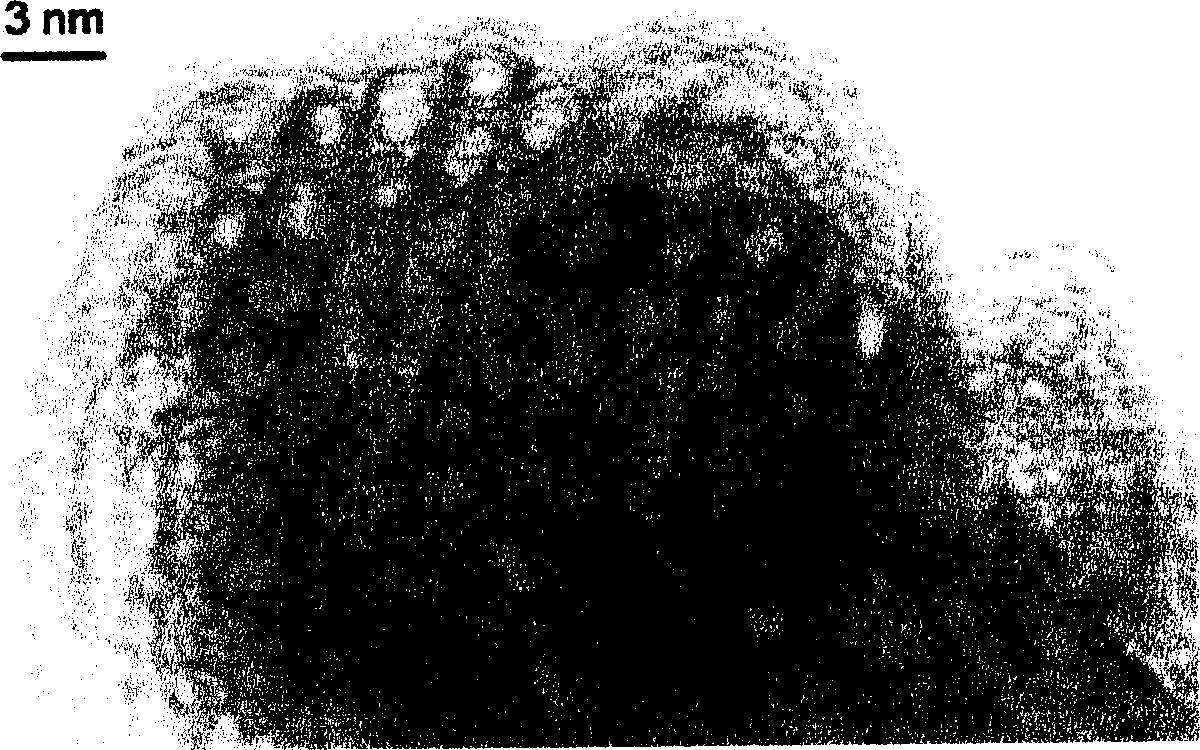

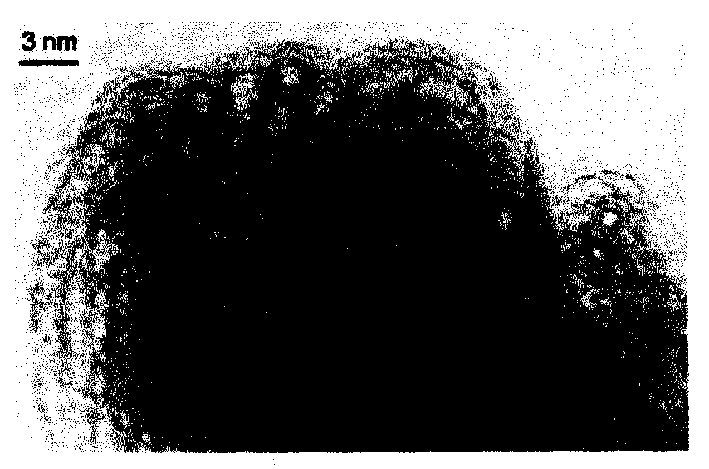

[0009] The invention relates to a method for synthesizing double-walled carbon nanotubes. It is carried out in the quartz tube of the horizontal quartz tube resistance furnace experimental device. According to the following process respectively: the molar ratio is 5: 1, 10: 1, 20: 1, weigh appropriate amount of ferrocene and sulfur, after mixing, grind in a mortar for 30 minutes to uniformly mix to prepare the catalyst precursor. Dissolve 300 mg, 400 mg, and 1000 mg of the prepared catalyst precursor in 20 ml of n-hexane to prepare a reaction solution. Raise the reaction temperature to 1100°C, 1150°C, 1180°C, feed 1 liter / min, 1.5 liter / min, 2 liter / min of argon and 0.3 liter / min, 0.4 liter / min, 0.6 liter / min Hydrogen, the reaction solution was sent into the quartz tube with a peristaltic pump at a rate of 0.3 ml / min. After 30 minutes, 40 minutes, and 50 minutes of reaction, the hydrogen was turned off and the argon flow was reduced, and the electric furnace was cooled to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com