Optical fibre lateral edge coupling method of pumping light source

A pump light source, fiber coupling technology, applied in the coupling of optical waveguides, optics, light guides, etc., can solve the problem of difficult to obtain coupling efficiency, and achieve high conversion efficiency, easy implementation, and improved conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

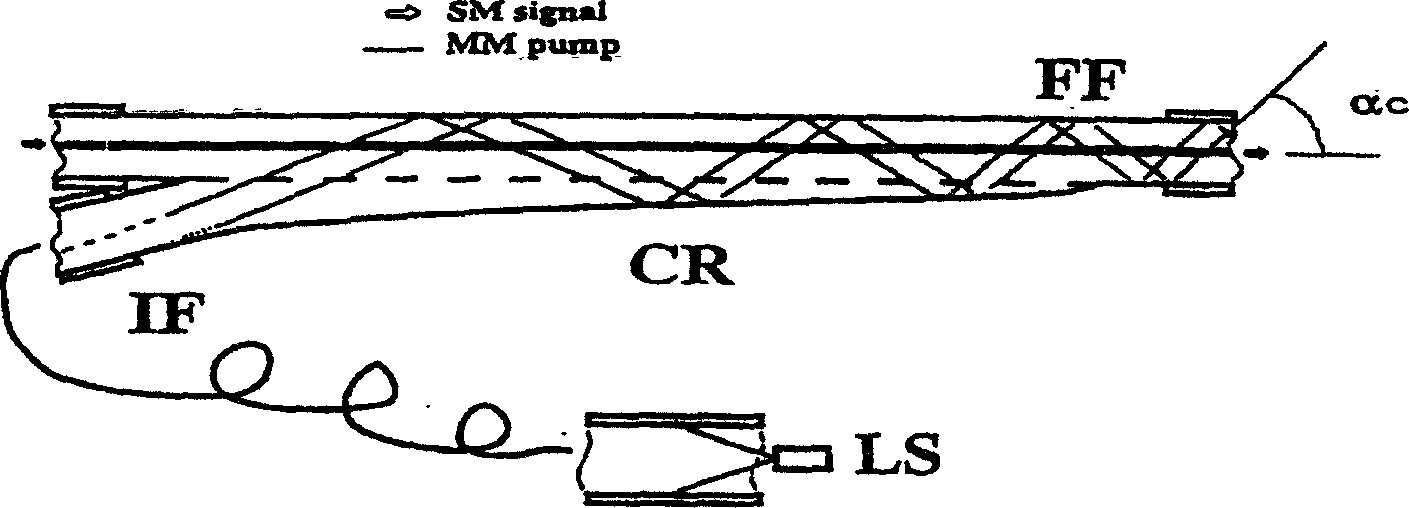

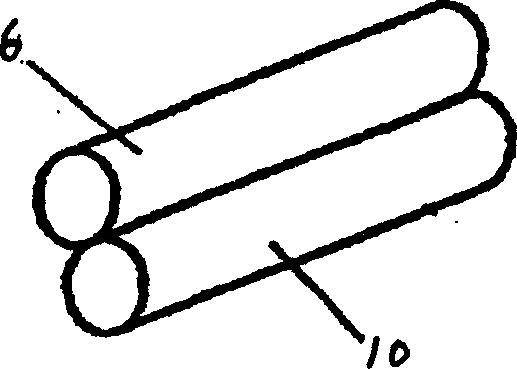

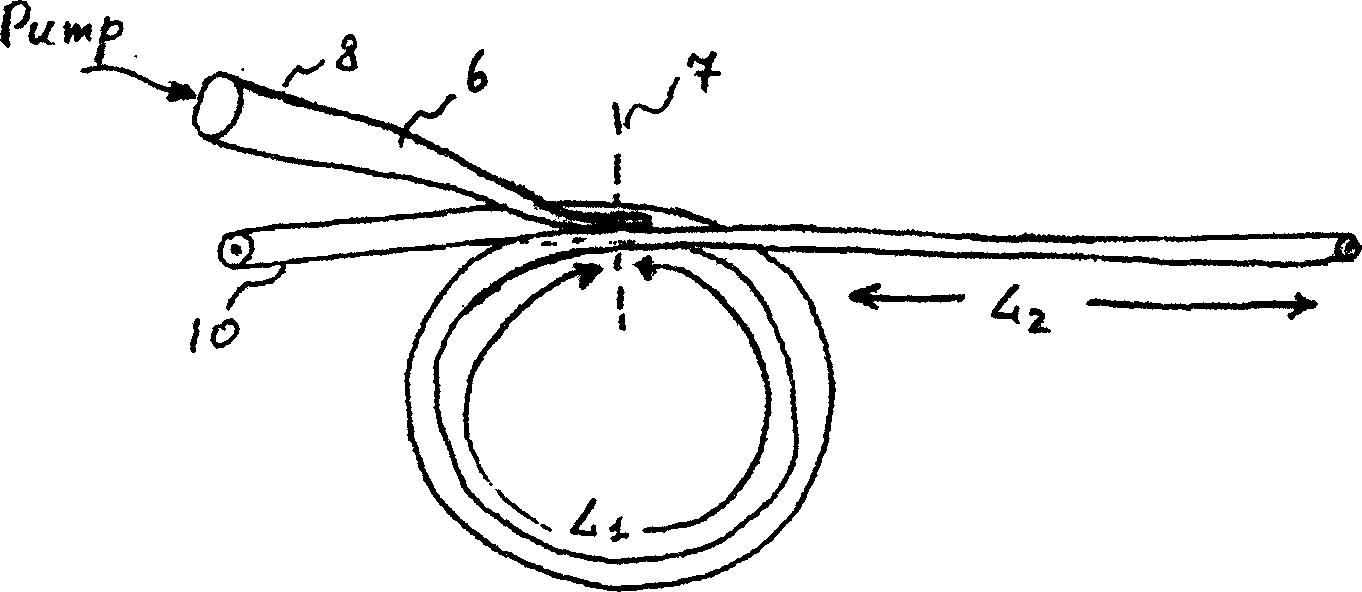

[0032] image 3 It shows a side coupling method of the present invention, the DC fiber 10 removes the protection layer in the coupling region 7, and the MM fiber 6 is a multimode fiber, the protection layer is removed in the coupling region 7 and gradually thinned. The DC optical fiber includes a coiled portion with a length of L1 and the remaining portion with a length of L2, and the total length is L1+L2. Therefore, in the coupling area 7, there are 3 cross-sections of the optical fiber, such as Figure 4 , 5 As shown, the sections of the DC fiber can be in optical contact with each other (eg Figure 4 ), or do not touch each other (such as Figure 5 ), the two sections of the DC fiber and the gradually thinned section of the pump fiber are optically in contact with each other, and the optical mutual contact refers to the transfer of the pump light source from the MM fiber end 8 to the DC fiber through fusion or mutual contact .

Embodiment 2

[0034] Figure 6 It shows a schematic diagram of another embodiment of the fiber side coupling method of the pump light source of the present invention. The difference from Embodiment 1 is that in Embodiment 1, when the MM optical fiber 6 and the DC optical fiber 10 reach the optimum in the coupling region 7 After optical contact, only the left input remains and the right input is removed. In this embodiment, the pump light source is introduced from the end 8 of the MM fiber on the left, is converted to the DC fiber in the coupling region 7 and is transmitted clockwise along the DC fiber, and another pump light source is introduced from the end 9 of the MM fiber on the right. Introduced, it is converted to the DC fiber in the coupling region 7 and trans-transmitted counterclockwise along the DC fiber to form bidirectional pumping. This coupling method can further improve the pumping efficiency of the DC fiber.

Embodiment 3

[0036] Figure 7 , 8. 9 shows the third embodiment of the present invention. In Embodiment 1 and Embodiment 2, the DC fiber is only wound into 2 circles, so only 2 sections are fused with a narrowed section of the MM fiber. In this embodiment, the DC fiber can be wound into 3 circles, 4 circles, 7 circles, etc., so that in the coupling region 7, the sections of multiple DC fibers are fused with the section of one MM fiber. The length of each turn of the DC fiber can be equal or unequal, so the distribution of pump light energy coupled to the entire DC fiber can be controlled along the DC fiber. In this embodiment, the MM fiber may or may not be attenuated due to the use of multiple coils of DC fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com