A solid electrolyte crystal material and process for preparing crystal film

A technology for solid electrolytes and crystal materials, which is used in crystal growth, chemical instruments and methods, metal material coating processes, etc. to achieve the effect of high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

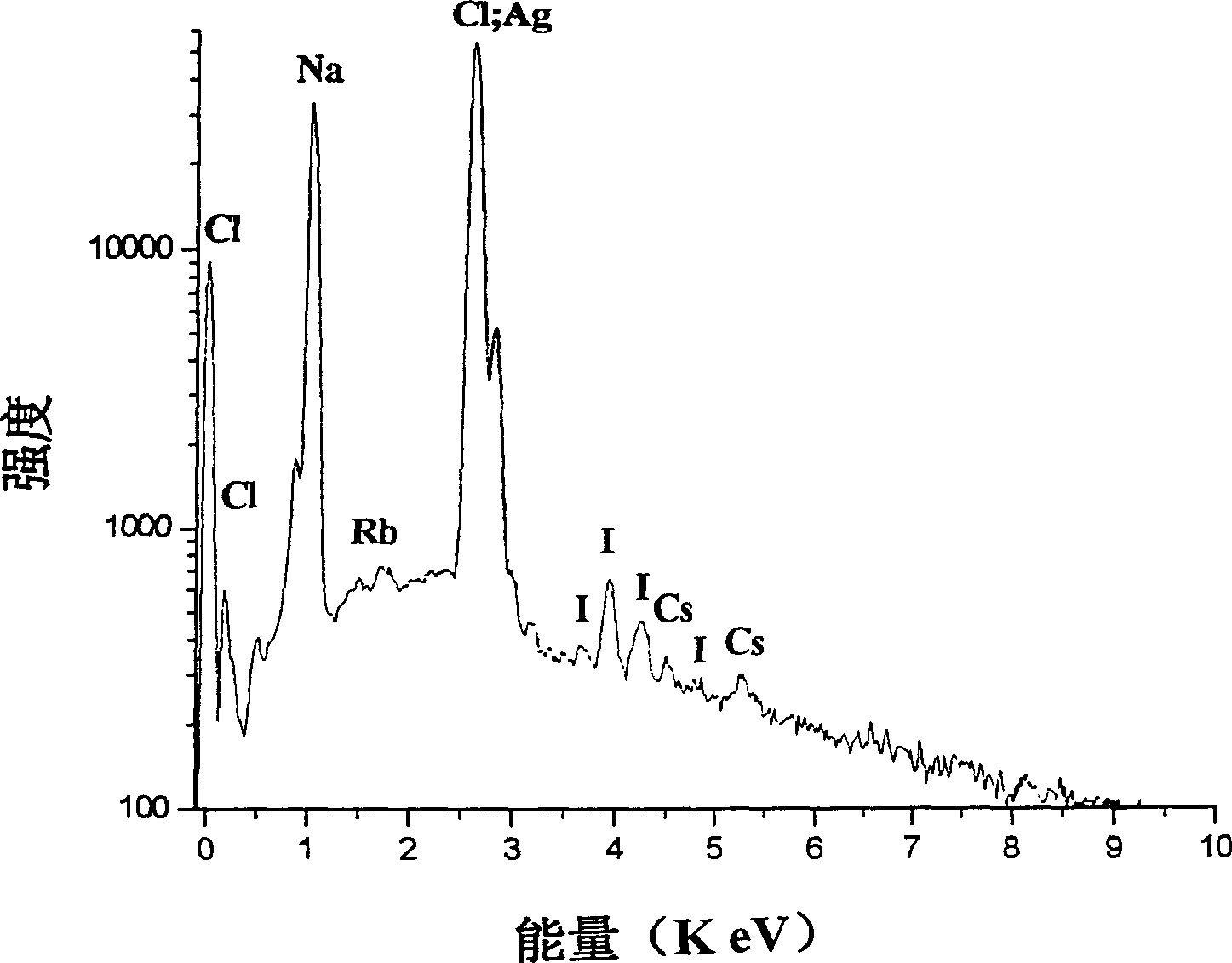

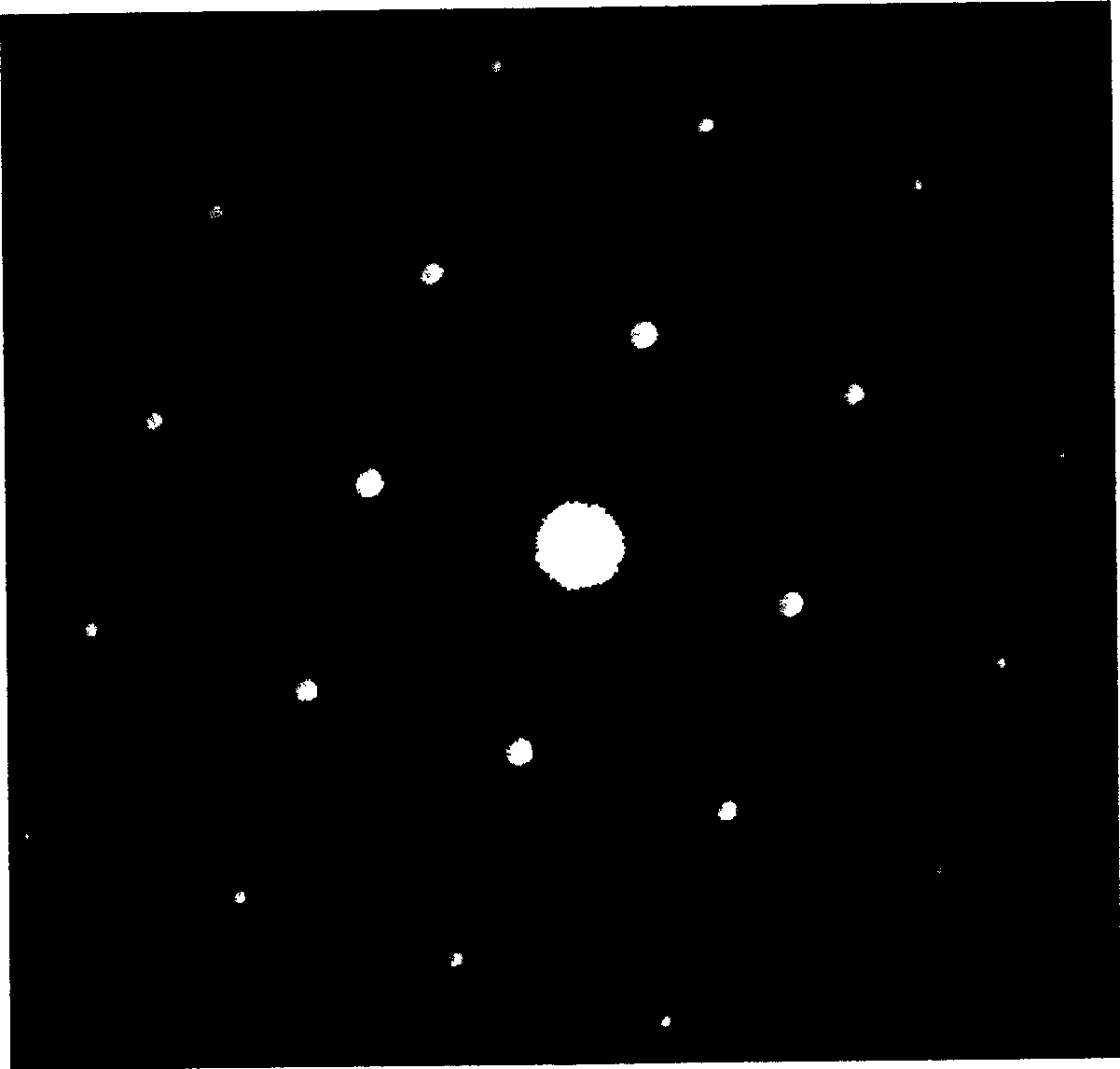

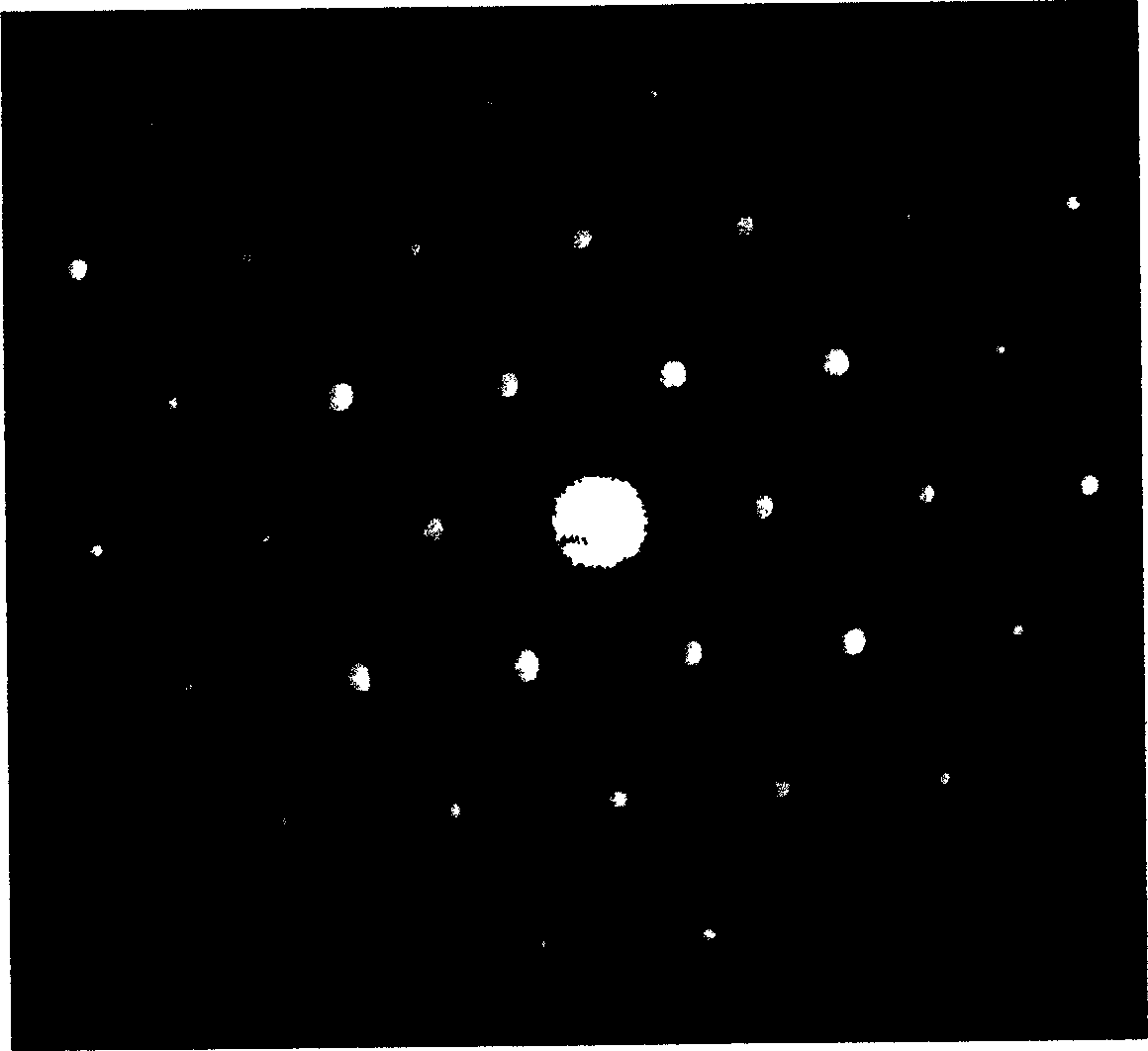

[0018] After mixing three kinds of binary iodide powders of RbI, CsI and AgI in molar ratio x=0.5 and y=0.15, (Rb x Cs 1-x I) y (AgI) 1-y The mixture is fully ground with a mortar, and then the powder is placed in the molybdenum (or tungsten) boat of the vacuum coating machine. When the pressure of the vacuum chamber is 2×10 -3 At Pa, cover the small boat with a baffle, and heat the small boat until the powder starts to melt, and keep it at this temperature. After all the powder is melted and no bubbles are generated, turn off the power to the small boat. Heat the newly cleaved NaCl crystal substrate pre-placed above the vacuum chamber to 75°C, then remove the baffle on the boat and heat the boat rapidly until white residue appears in the boat (film deposition rate is 5nm / s), Immediately cover the boat with a baffle, cut off the heating current of the boat, so far, a new solid electrolyte material Rb 0.5 Cs 0.5 Ag 4 I 5 The crystal thin film is prepared.

Embodiment 2

[0020] After mixing three kinds of binary iodide powders of RbI, CsI and AgI in molar ratio x=0.5 and y=0.16, (Rb x Cs 1-x I) y (AgI) 1-y The mixture is fully ground with a mortar, and then the powder is placed in the molybdenum (or tungsten) boat of the vacuum coating machine. When the pressure of the vacuum chamber is 1.4×10 -3 At Pa, cover the small boat with a baffle, and heat the small boat until the powder starts to melt, and keep it at this temperature. After all the powder is melted and no bubbles are generated, turn off the power to the small boat. Heat the newly cleaved NaCl crystal substrate previously placed above the vacuum chamber to 55°C, then remove the baffle on the boat and heat the boat rapidly until white residue appears in the boat (film deposition rate is 15nm / s), Immediately cover the boat with a baffle, cut off the heating current of the boat, so far, a new solid electrolyte material Rb 0.5 Cs 0.5 Ag 4 I 5 The crystal thin film is prepared.

Embodiment 3

[0022] After mixing three binary iodide powders of RbI, CsI and AgI in molar ratio x=0.5 and y=0.155, (Rb x Cs 1-x I) y (AgI) 1-y Grind the mixture fully with a mortar, and then put the powder into the molybdenum (or tungsten) boat of the vacuum coating machine. When the pressure of the vacuum chamber is less than 1.6×10 -3 At Pa, cover the small boat with a baffle, and heat the small boat until the powder starts to melt, and keep it at this temperature. After all the powder is melted and no bubbles are generated, turn off the power to the small boat. Heat the newly cleaved NaCl crystal substrate pre-placed above the vacuum chamber to 65°C, then remove the baffle on the boat and heat the boat rapidly until white residue appears in the boat (film deposition rate is 10nm / s), Immediately cover the boat with a baffle, cut off the heating current of the boat, so far, a new solid electrolyte material Rb 0.5 Cs 0.5 Ag 4 I 5 The crystal thin film is prepared.

[0023] Although...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com