Method for selecting mask manufacturer for producing optical mask

A technology for manufacturers and photomasks, applied in the fields of original components for photomechanical processing, semiconductor/solid-state device manufacturing, optics, etc., can solve the problems of high mask prices and achieve the effect of easy selection of methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

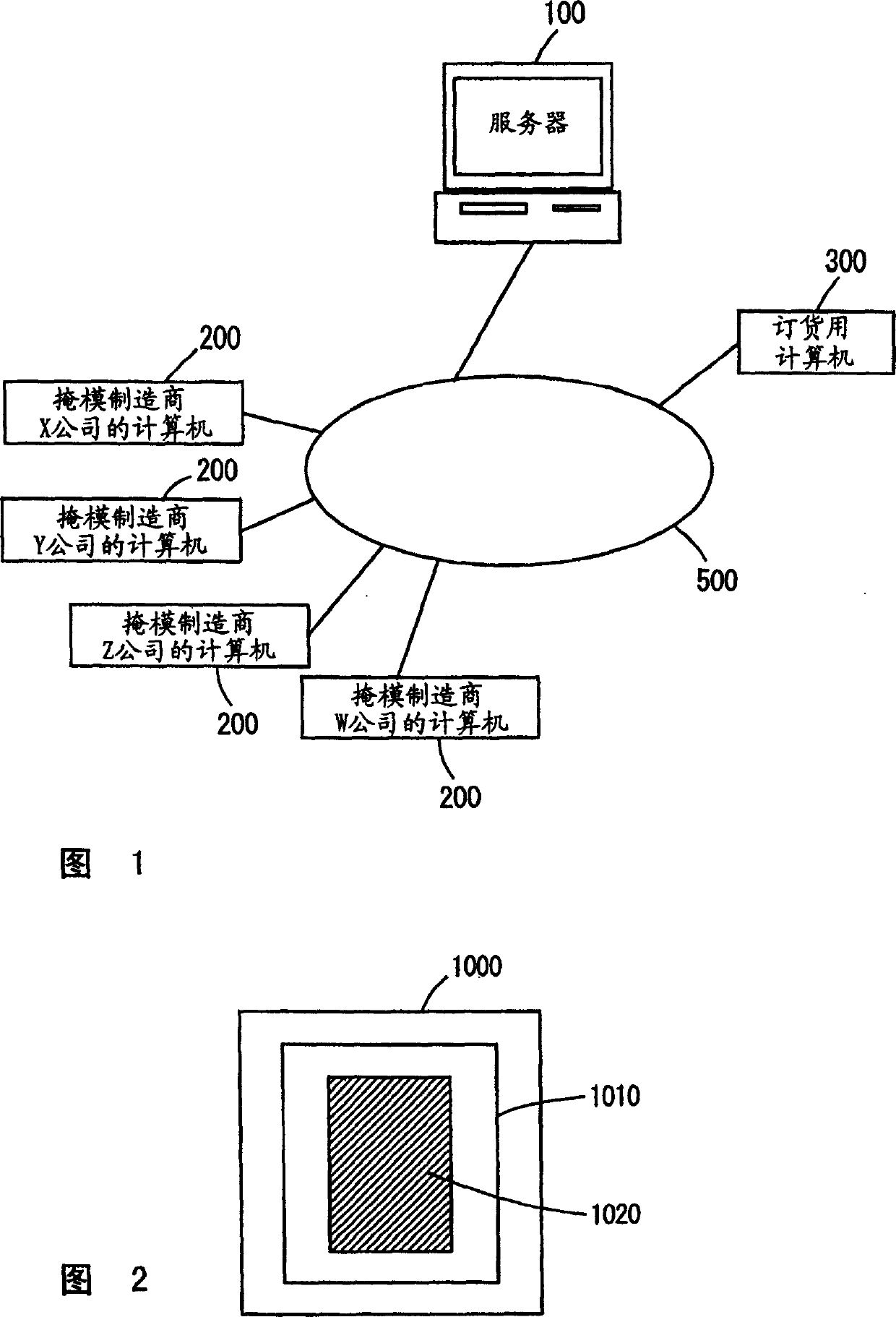

[0029] With reference to Fig. 1, the mask manufacturer selection system of the present embodiment comprises: the computer 200 of a plurality of mask manufacturers who manufacture photomask; The ordering computer 300 of the manufacturer's computer 200; and the wafer manufacturer's server 100 connected to these computers via the network 500.

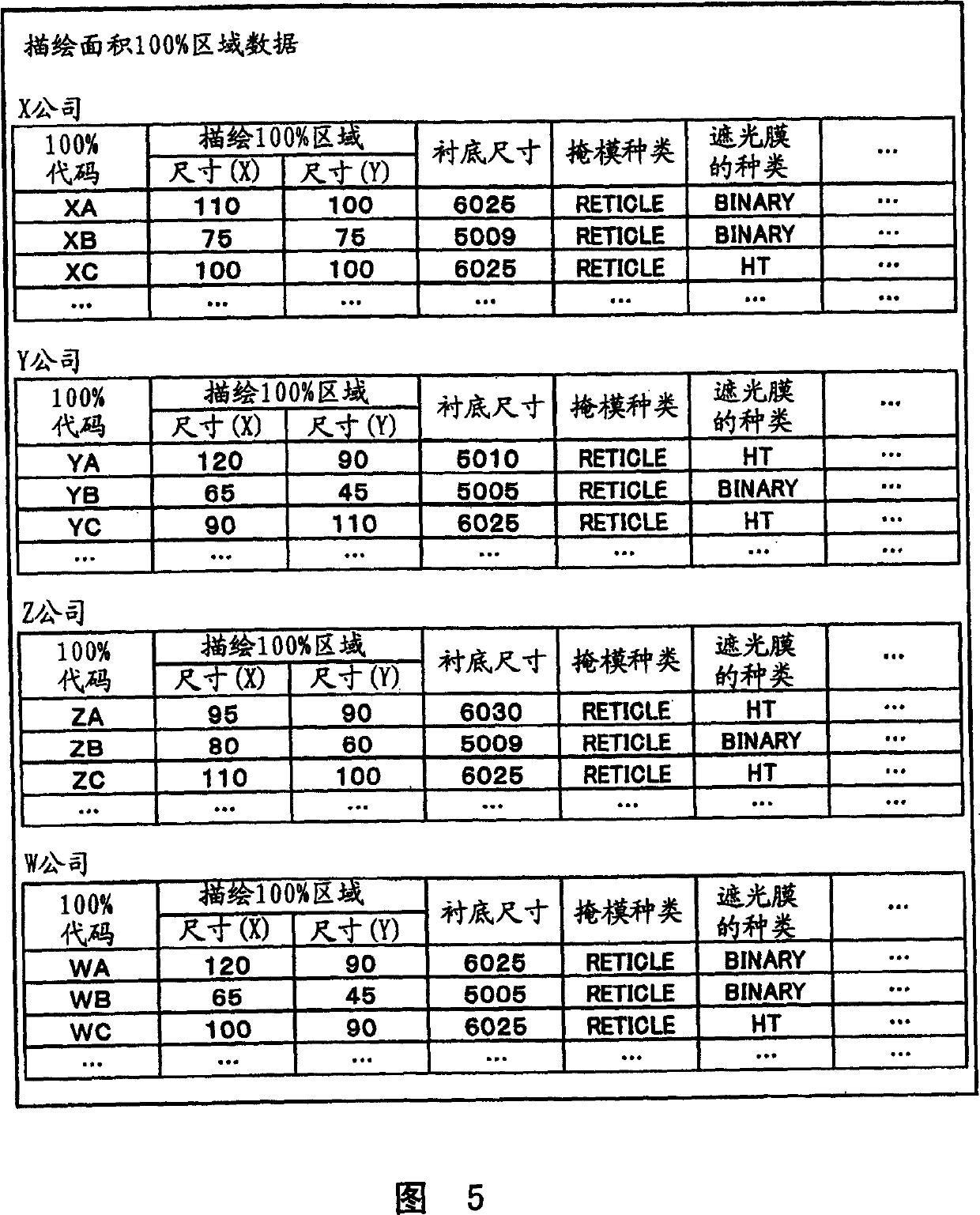

[0030] The server 100 stores order detail data including a drawing area of a photomask. The computer 200 of the mask maker establishes and stores the maximum drawing area in the substrate on which the photomask is drawn as area data of 100% of the drawing area. The mask maker's computer 200 creates and stores unit price data of the photomask corresponding to the ratio of the drawing area of the photomask to the maximum drawing area. These delineation area 100% area data and photomask unit price data are established for each mask maker.

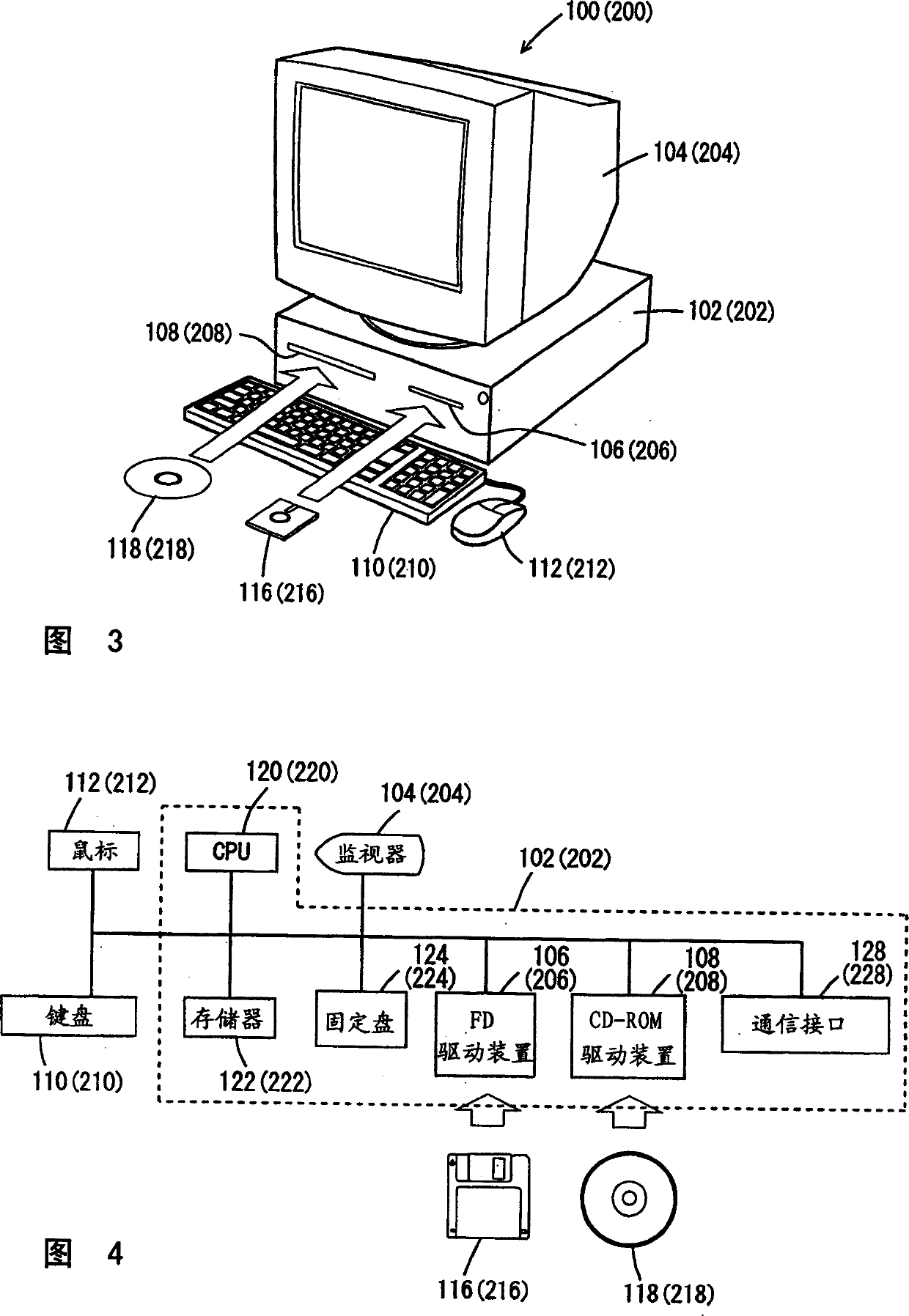

[0031] Referring to FIG. 2 , the drawing area 100% area will be described. In the photomask 1000...

no. 2 Embodiment

[0082] Next, a mask maker selection system according to a second embodiment of the present invention will be described. Note that the hardware configurations of the wafer maker's server 100 and the mask maker's computer 200 other than the database and flowchart shown below are the same as those of the first embodiment described above. Therefore, detailed descriptions of them will not be repeated here.

[0083] Referring to FIG. 12 , the specification and use database will be described for each photomask process stored in the fixed disk 220 of the mask manufacturer's computer 200 . As shown in FIG. 12, for each mask name and process name, the database stores the chip size of the device, the order of photomasks used in the crystal wafer manufacturing process, the kind and arrangement of transfer marks, and photomask manufacturing conditions. , the purpose for which the device was manufactured, the period of manufacture and the destination of shipment of the device.

[0084] Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com