Preparation of lithium cobaltate as anode material of lithium ion cell from nano tricobalt tetroxide

A lithium-ion battery and cobalt tetroxide technology, which is applied in battery electrodes, chemical instruments and methods, and active material electrodes, etc., can solve the problems of limiting the application of liquid-phase synthesis methods, difficulty in industrialization, etc., achieve low hardness, improve product performance, and mix materials uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

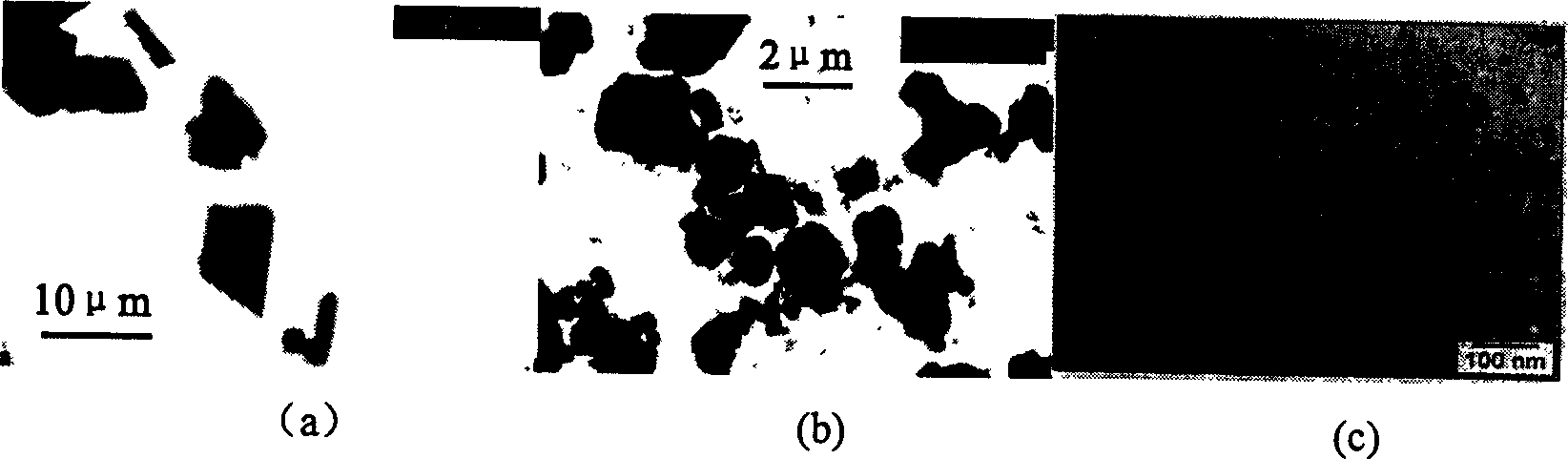

[0033] Nano cobalt tetroxide is prepared according to the method (patent application number: 01135170.5), and the particle size is 20-50nm.

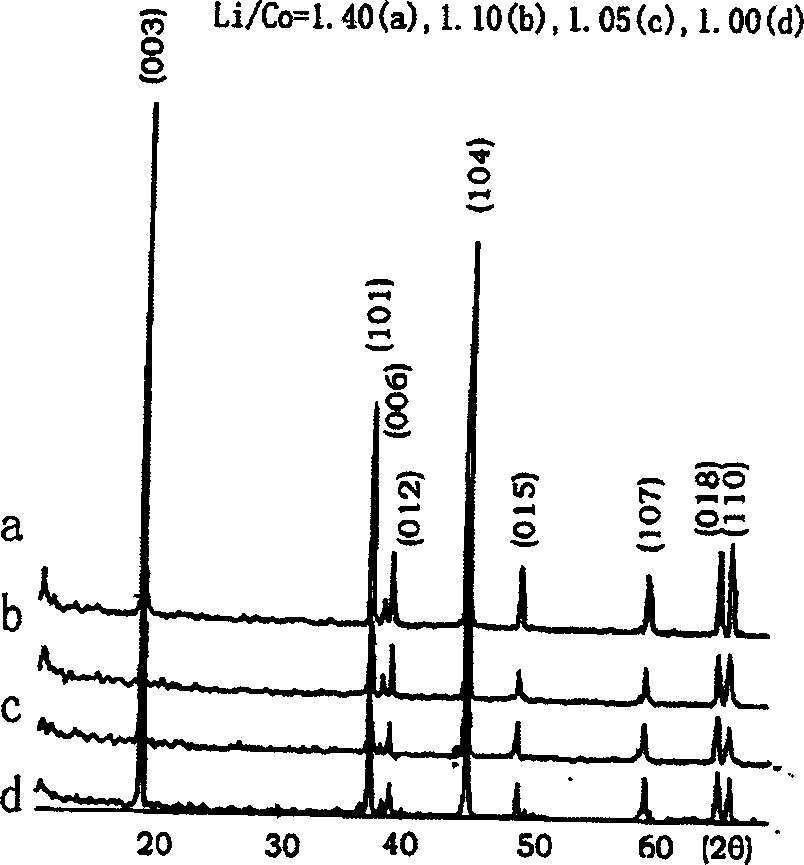

[0034] Raw material Li 2 CO 3 and Nano Co 3 o 4 Fully mix according to the molar ratio Li / Co=1.05, roast in the first stage, heat up to 750°C at a speed of 2°C / min, keep it for 6 hours, and then cool down at a speed of 2°C / min to complete the first stage of heating; after ball milling, the second stage Roasting, then raising the temperature to 900°C at a heating rate of 2°C / min, keeping the temperature for 6 hours, and cooling down to obtain a block product. Finally, the lithium cobaltate powder was prepared by jet crushing and classification. The weight ratio of ball powder in the mixture is 1-1.2:1, and the air pressure for product crushing and classification is 2.5Kg. Product indicators:

[0035] The structure conforms to JCPDS standard card 16-427;

[0036] Granularity: D 50 =9.046μm, D 5 - D95 = 3.30-57.09 μm;

[0037] Spe...

Embodiment 2

[0042] Nano cobalt tetroxide is prepared according to the method (patent application number: 01135170.5), and the particle size is 20-50nm.

[0043] Raw material Li 2 CO 3 and Nano Co 3 o 4 Fully mix according to the molar ratio Li / Co=1.03, roast in the first stage, heat up to 750°C at a speed of 4°C / min, keep it warm for 6 hours, and then cool down at a speed of 4°C / min to complete a stage of heating; after ball milling, the second stage Roasting, then raising the temperature to 900°C at a heating rate of 4°C / min, keeping the temperature for 6 hours, and cooling down to obtain a block product. Finally, the lithium cobaltate powder was prepared by jet crushing and classification. The weight ratio of ball powder in the mixture is 1-1.2:1, and the air pressure for product crushing and classification is 2.5Kg. Product indicators:

[0044] The structure conforms to JCPDS standard card 16-427;

[0045] Granularity: D 50 =8.406μm, D 5 - D95 = 3.35-21.24 μm;

[0046] Specif...

Embodiment 3

[0051] Nano cobalt tetroxide is prepared according to the method (patent application number: 01135170.5), and the particle size is 20-50nm.

[0052] Raw material Li 2 CO 3 and Nano Co 3 o 4 Mix thoroughly according to the molar ratio Li / Co=1.05, roast in the first stage, raise the temperature to 750°C at a speed of 5°C / min, keep it for 6 hours, and then cool down at a speed of 5°C / min to complete the first stage of heating; after ball milling, the second stage Roasting, then raising the temperature to 900°C at a heating rate of 5°C / min, keeping the temperature for 8 hours, and cooling down to obtain a block product. Finally, the lithium cobaltate powder was prepared by jet crushing and classification. The weight ratio of ball powder in the mixture is 1-1.2:1, and the air pressure for product crushing and classification is 2.5Kg. Product indicators:

[0053] The structure conforms to JCPDS standard card 16-427;

[0054] Granularity: D 50 = 10.495 μm, D 5 - D95 = 3.11-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com