Preparation method of high silver carrying ZSM-5 zeolite deiodine adsorbing agent

A technology of ZSM-5 and adsorbent, which is applied in the field of effective deiodination adsorbent, can solve problems such as hindering the diffusion of silver ions and affecting the silver loading amount of deiodination adsorbent, and achieves the effect of simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

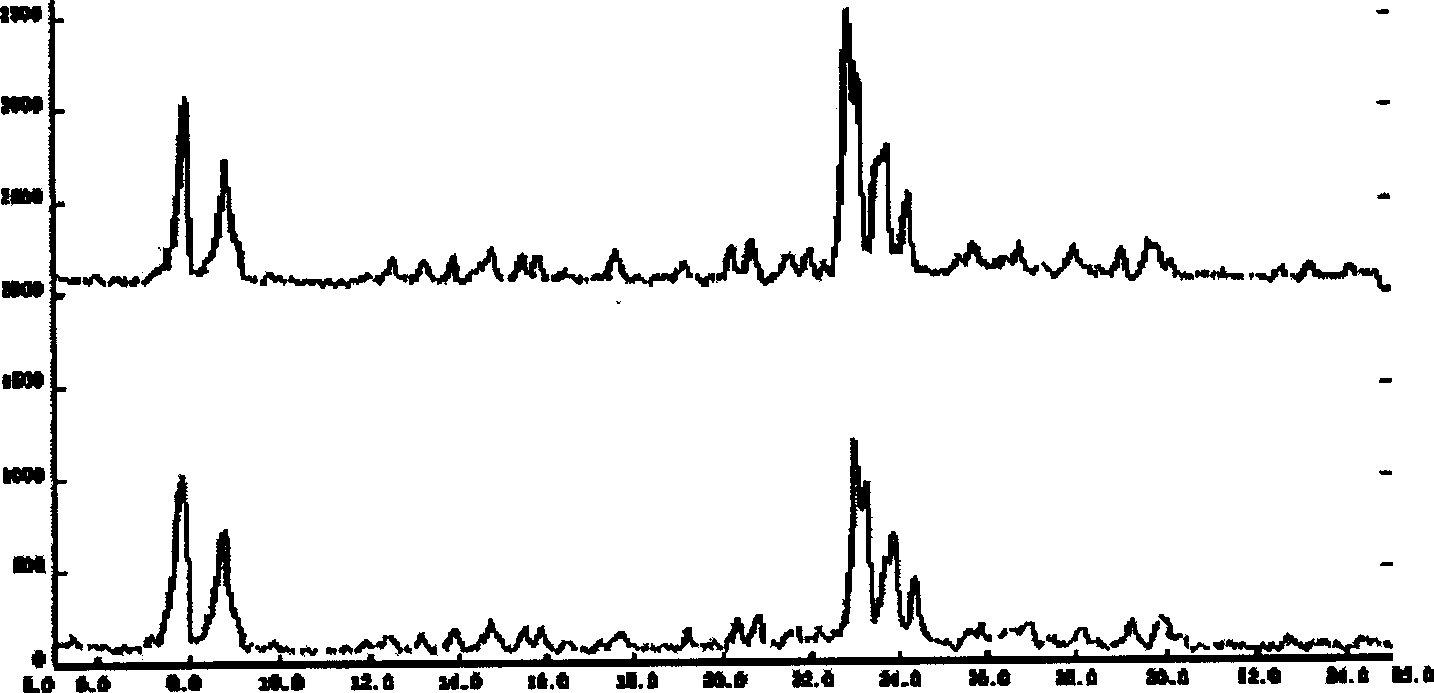

[0028] SiO 2 / Al 2 o 3 75g of H-ZSM-5 zeolite powder of ≈26 and 25g of white carbon black are kneaded and dried, then added to a 30% aluminum nitrate solution, soaked for 2 hours, dried, and then sealed in 10% tetrapropylammonium hydroxide solution, after 1.5 days of hydrothermal treatment at 180°C, it was calcined at 600°C for 5 hours. It was determined that its SiO 2 / Al 2 o 3 ≈28, crystallinity>92%, n-hexane adsorption>113mg / g, XRD spectra of samples before and after hydrothermal reaction are shown in Figure 1 (the upper line is after crystal transformation).

Embodiment 2

[0030] SiO 2 / Al 2 o 3 ≈14 85g of H-ZSM-5 zeolite powder with 15g of SiO 2 / Al 2 o 3 ≈14 amorphous silica-alumina adhesive is mixed and dried, then sealed in a sealed reaction kettle filled with 5% ethylamine aqueous solution, heat-treated with ethylamine / water mixed steam at 200°C for 4 days, and then baked at 500°C for 6 hours . It was determined that its SiO 2 / Al 2 o 3 =15, crystallinity>90%, n-hexane adsorption>110mg / g.

Embodiment 3

[0032] The sample that embodiment 1 makes carries out silver ion exchange with 0.05mol / L silver nitrate in ion exchange column, liquid / solid=30 / 1, space velocity 0.5hr -1 , temperature 95 ° C, prepared Ag-ZSM-5 deiodination adsorbent. After washing and drying, the silver content was analyzed by EDX to be 16.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com