Sludge treatment method and its artificial wetland treatment pool

A technology for constructed wetland and sludge treatment, applied in the field of sewage and sludge treatment, can solve the problems of high price, fragile and disproportionate sewage treatment cost of plate filter press.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

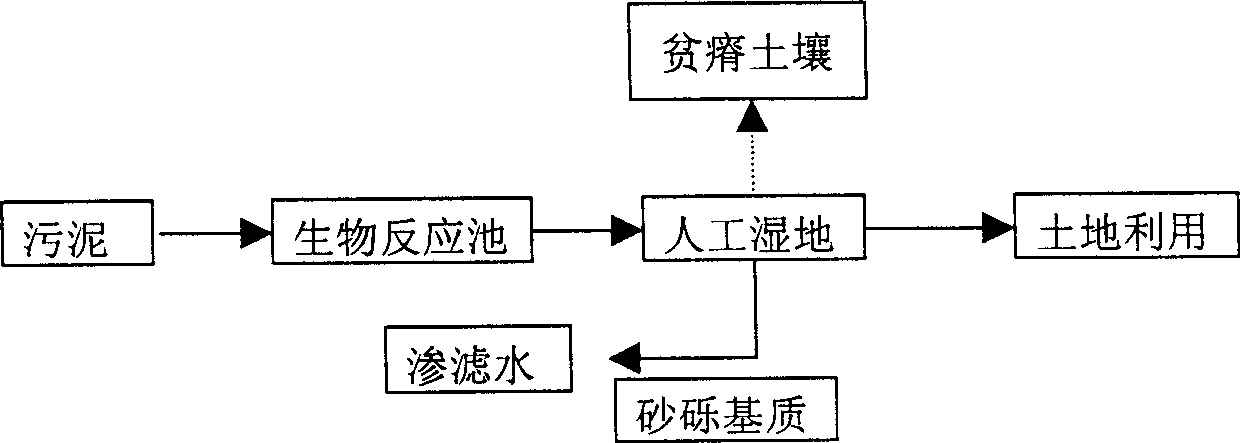

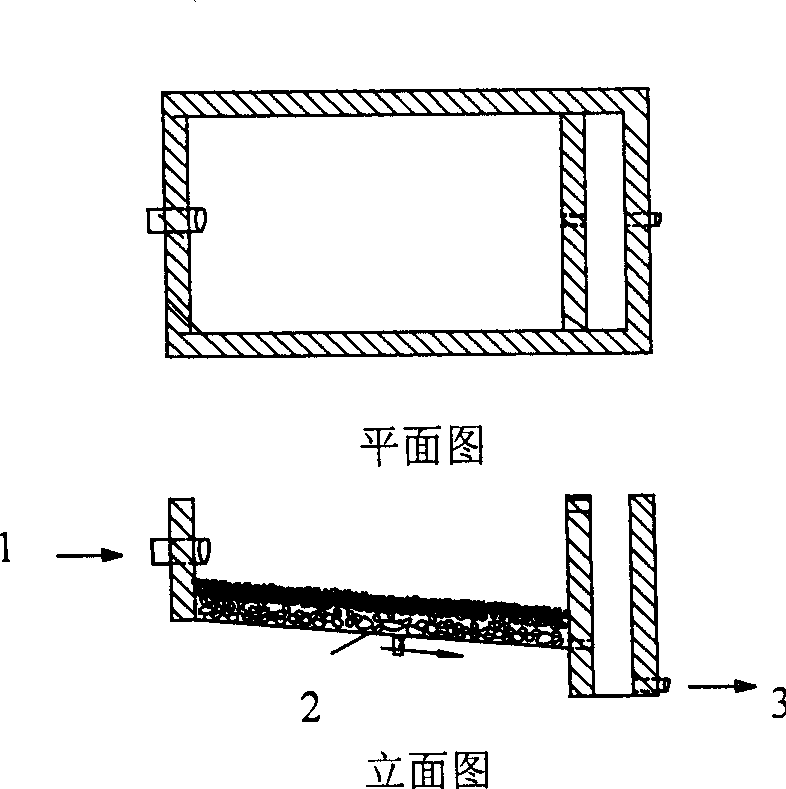

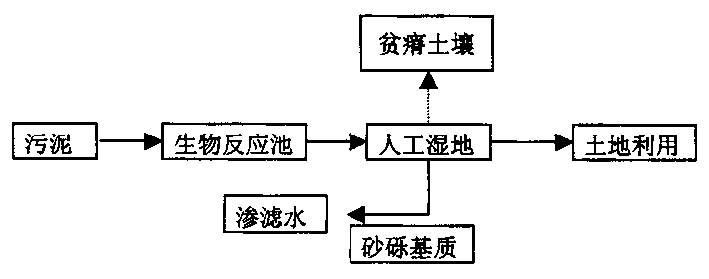

[0021] For a small sewage treatment plant that processes 2,000 tons of domestic sewage per day, it produces 10 tons of sludge per day (with a moisture content of more than 99%). The unconcentrated and dehydrated sludge from the sewage plant flows into the biological reaction tank with the bacterial solution of Thiobacillus as the dominant species to remove part of the heavy metals in the sludge; then the reacted sludge flows into the treatment tank body and The sludge artificial wetland treatment pool composed of artificial matrix, according to the amount of sludge, the pool body is designed to be 200m 2 A square rectangular pool, the ratio of the length to width of the pool body is 3:1, the bottom surface of the pool body is a slope bottom surface with a slope of 0.03, and a layer of artificial substrate is laid on the bottom surface of the pool body. The artificial substrate is crushed stone with a thickness of 0.5 meters, and the artificial matrix is divided into two laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com