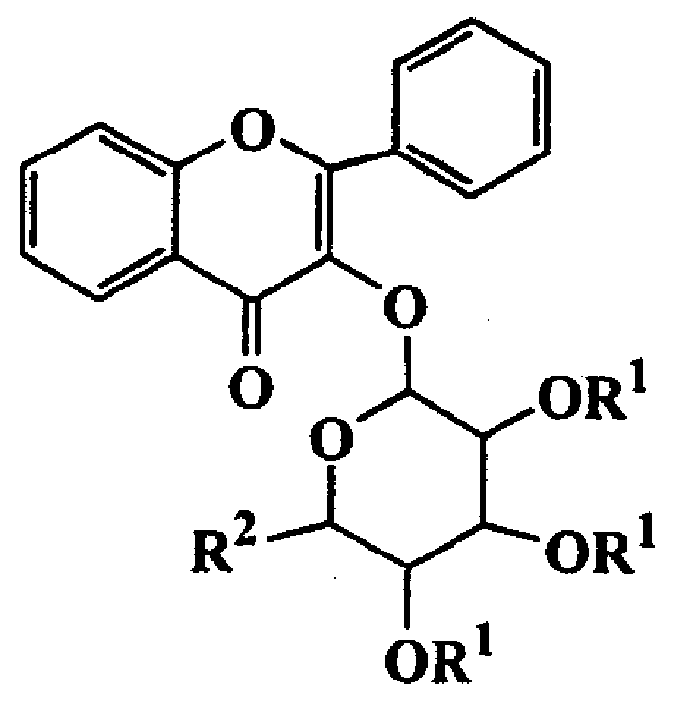

3-glyeosyl flavone or its derivative and its preparation method and use

A technology of glycosyl flavonoids and derivatives, which is applied in the field of flavonoids and can solve problems such as difficult handling, many reaction steps, and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Synthesis of 3-(2,3,4-triacetyl-L-rhamnopyranosyl)flavone:

[0031] 3-Hydroxyflavone (2.751 g, 0.0116 mol) and 2,3,4-triacetyl-1-oxo-α-L-rhamnopyranosyl trichloroethylimine (5.022 g, 0.0116 mol) were mixed , after vacuum drying for 2 h, 180 ml of anhydrous CH was added to the mixture 2 Cl 2 , the system was cooled to -42°C in a liquid nitrogen-ethanol bath, N 2 Trimethylsilyl trifluoromethanesulfonate (TMSOTf)-247 μl was added dropwise under protection. After the addition was completed, the reaction system was removed from the cooling bath, and the reaction system gradually returned to room temperature. Ethyl acetate=3:2) After monitoring the reaction, triethylamine was added to the system to terminate the reaction, and the solvent was removed by a rotary evaporator to obtain a brown-yellow viscous liquid, which was separated and purified by chromatography on a silica gel column (eluent For: petroleum ether: ethyl acetate = 3: 1)) to obtain 1.215 g of whit...

Embodiment 2

[0040] The synthesis of embodiment 2.3-L-rhamnopyranosyl flavone:

[0041] Add 3-(2,3,4-triacetyl-L-rhamnopyranosyl)flavone (0.601 g, 1.178 mmol) to CH 3 After OH25ml was dissolved, NH 3To saturation, the time is about 4h. After standing at room temperature for 48h, thin-layer chromatography (developing solvent: petroleum ether: ethyl acetate = 1:5) monitors that there is no raw material in the system, and the solvent is removed by a rotary evaporator to obtain an orange-yellow solid. Separation and purification by silica gel column chromatography (eluent: petroleum ether: ethyl acetate = 2:5) gave 0.385 g of white solid, mp.96-99°C, yield 83.6%. Compound by 1 H-NMR, 13 C-NMR, IR, MS and elemental analysis for structural verification, the results show that its structure is correct, the data are as follows:

[0042] 1 H-NMR (300MHz, DMSO-D6):

[0043] 8.12 (d, 1H J = 7.71Hz) 7.91 (m, 2H) 7.83 (t, 1H, J = 8.20, 7.22Hz) 7.77 (d, 1H, J = 8.20Hz) 7.58 (m, 3H) 7.51 (t, 1H, J=...

Embodiment 3

[0051] Synthesis of Example 3.3-(2,3,4,6-tetraacetyl-D-glucopyranosyl)flavone (VI):

[0052] 3-Hydroxyflavone (1.088g, 4.57mmol) was mixed with 2,3,4,6-tetraacetyl-1-oxo-α-D-glucopyranosyltrichloroethylimine (2.251g, 4.57mmol) , after vacuum drying for 2 h, 150 ml of anhydrous CH was added to the mixture 2 Cl 2 , the system was cooled to -78°C in a liquid nitrogen-ethanol bath, N 2 98 μl of trimethylsilyl trifluoromethanesulfonate (TMSOTf) was added dropwise under protection. After the addition was completed, the reaction system was removed from the cooling bath, and the reaction system gradually returned to room temperature. Ethyl ester = 3: 2) After monitoring the reaction, triethylamine was added to the system to terminate the reaction, and the solvent was removed by a rotary evaporator to obtain a brownish-yellow viscous solid, which was separated and purified by chromatography on a silica gel column (the eluent was Petroleum ether:ethyl acetate=3:1) to obtain 1.25g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com