Original water biologic pretreatment method using suspended padding and apparatus therefor

A biological pretreatment and water treatment device technology, applied in the field of suspended filler raw water biological pretreatment methods and devices, can solve the problems of large floor area, increased sludge treatment process, and very high uniformity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

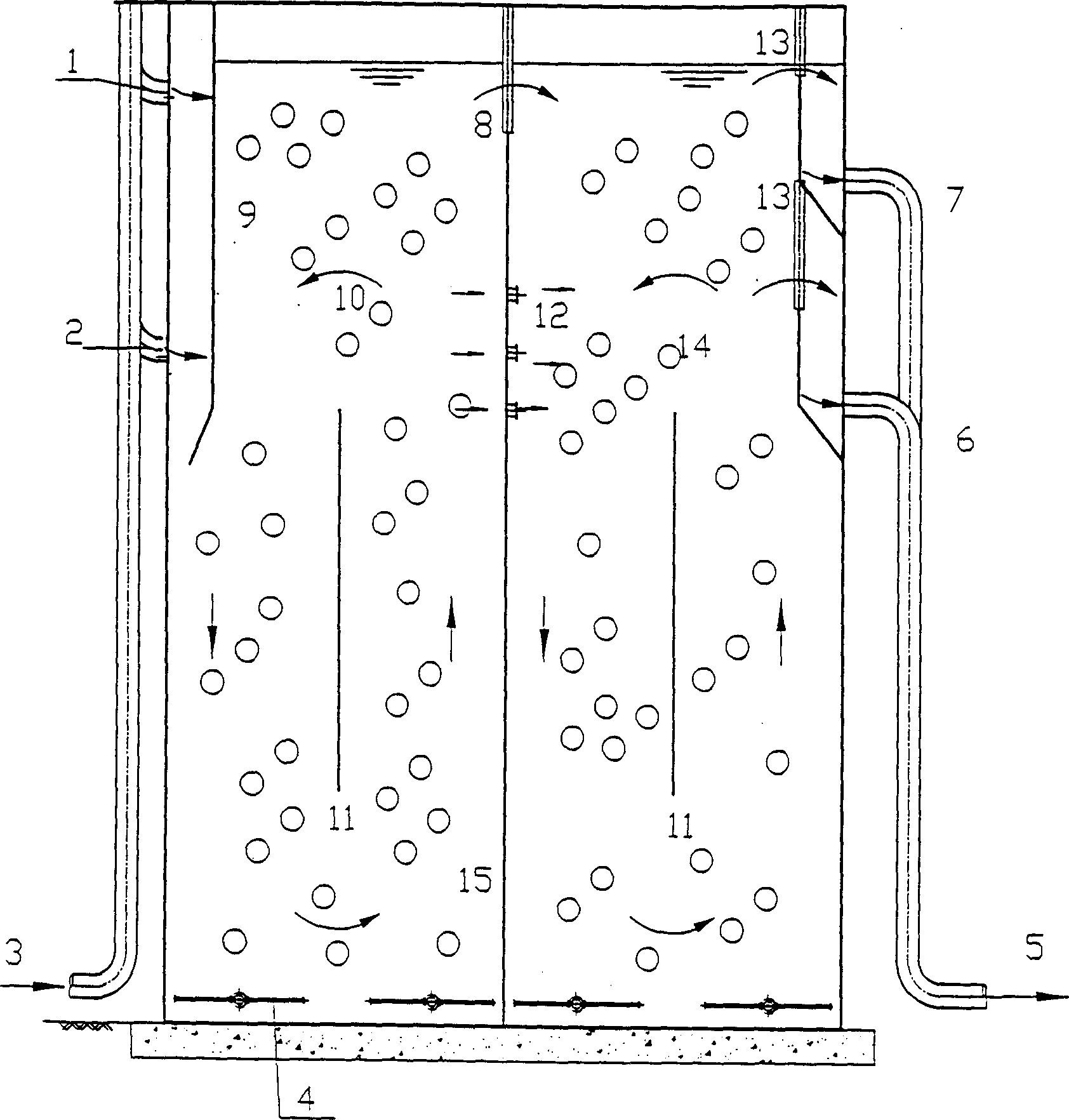

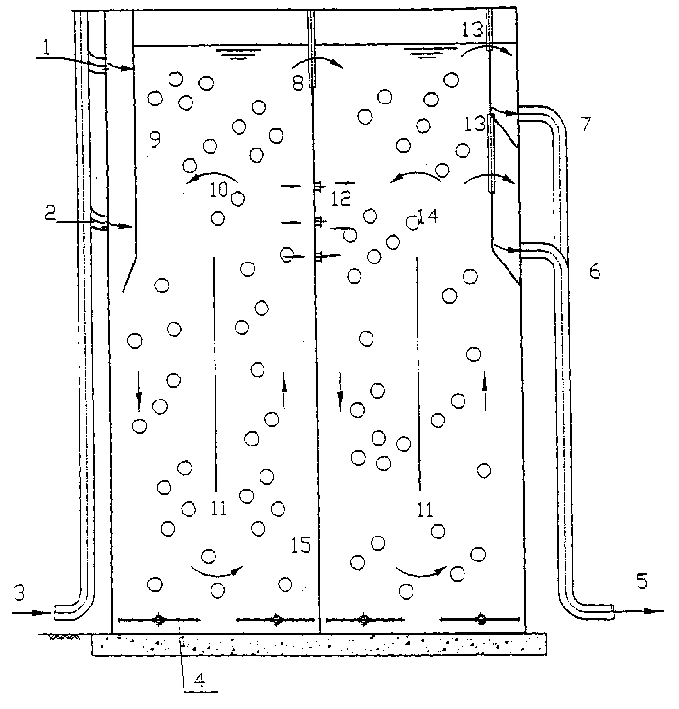

[0005] Such as figure 1 Shown, the present invention is a kind of suspended filler raw water biological pretreatment method and device, wherein, said this suspended filler raw water biological pretreatment method is a kind of method of biological contact oxidation, adopts a kind of suspended filler in the prior art , the suspended filler 14 is a biological carrier in the prior art (patent number: 97234855.7), the suspended filler 14 is a carrier with a regular structure, the carrier can be granular, and the carrier The specific gravity is between 0.8-1.0. The carrier can be a sphere with a diameter of 5mm-100mm, or a cylinder between Φ5mm×Φ5mm-Φ100mm×Φ100mm. The specific surface area of the carrier is 100cm2 / cm3-3000cm2 / cm3, the carrier is placed in a water treatment device, the filling rate of the suspended filler in the device is between 30% and 80%, and the raw water is introduced into the In the water treatment device, the aeration device in the water treatment device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com