Coal-fired mercury discharge control method based on semi-dry process

An emission control, semi-dry technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of low total mercury removal rate, difficult to popularize and apply, difficult to remove, etc., and achieve easy adsorption. , improve the utilization rate, the effect of large reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

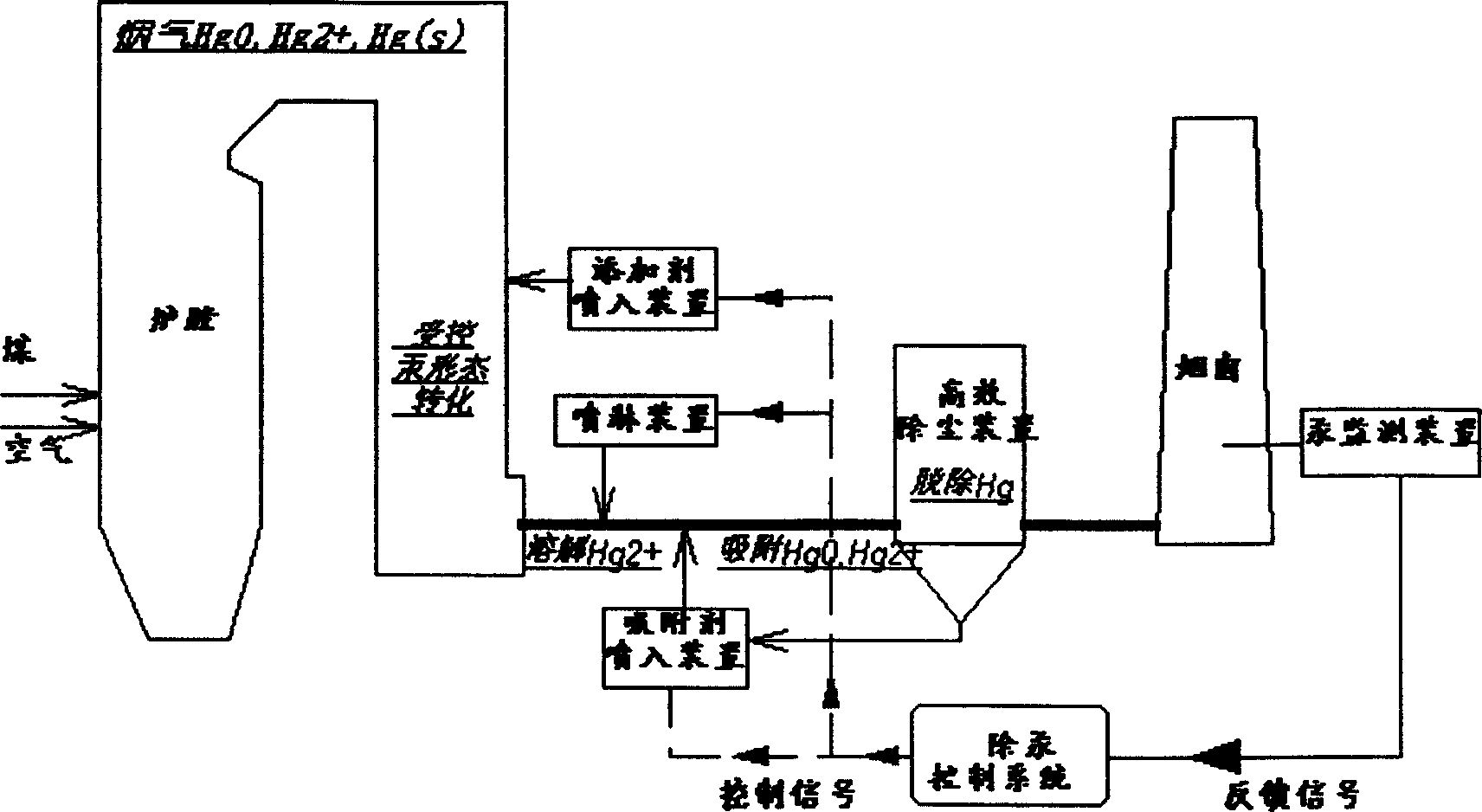

[0036] Such as figure 1 , a coal-fired power plant boiler, the flue gas flow rate is 8.31×10 5 N m 3 / h, the mercury content in the generated flue gas is 6.8μg / Nm 3 . The additive is selected as HCl (excessive HCl can be removed in the desulfurization device and will not cause secondary pollution), the injection amount of HCl / Hg is 600, and it is injected when the flue gas temperature is 900°C, and there is oxygen in the flue gas Under this condition, a part of elemental mercury is oxidized to oxidized mercury, and the speciation analysis is carried out by the Ontario-Hydro method. The result shows that the ratio of elemental mercury to oxidized mercury is 80%; the reaction chemical equation is as follows:

[0037]

[0038] When the flue gas temperature is 150°C, a solution containing 0.5% hydrogen peroxide is sprayed into the flue gas through the spraying device, and the liquid flow rate is 600Kg / h. The hydrogen peroxide is decomposed by heat to generate active oxyg...

Embodiment 2

[0048] Such as figure 1 Show, the flue gas flow rate, the content of mercury in the flue gas are the same as in Example 1, and the additive is selected as FeCl 3 , the injection amount of FeCl 3 / Hg is 1600, sprayed when the flue gas temperature is 800°C, oxidizes a part of elemental mercury to oxidized mercury, and uses the Ontario-Hydro method for speciation analysis, the result shows that the ratio of elemental mercury to oxidized mercury is 50%; The reaction chemical equation is as follows:

[0049]

[0050] When the flue gas temperature is 160°C, the solution containing 0.4% sodium hypochlorite is sprayed into the flue gas through the spraying device, and the liquid flow rate is 600Kg / h, so that the ratio of elemental mercury to be oxidized to mercuric chloride or mercuric oxide is increased to 80%. At the same time, the temperature of the flue gas is reduced to 100 degrees; then, FeCl is injected into the flue gas 3 Impregnated modified vermiculite adsorbent, t...

Embodiment 3

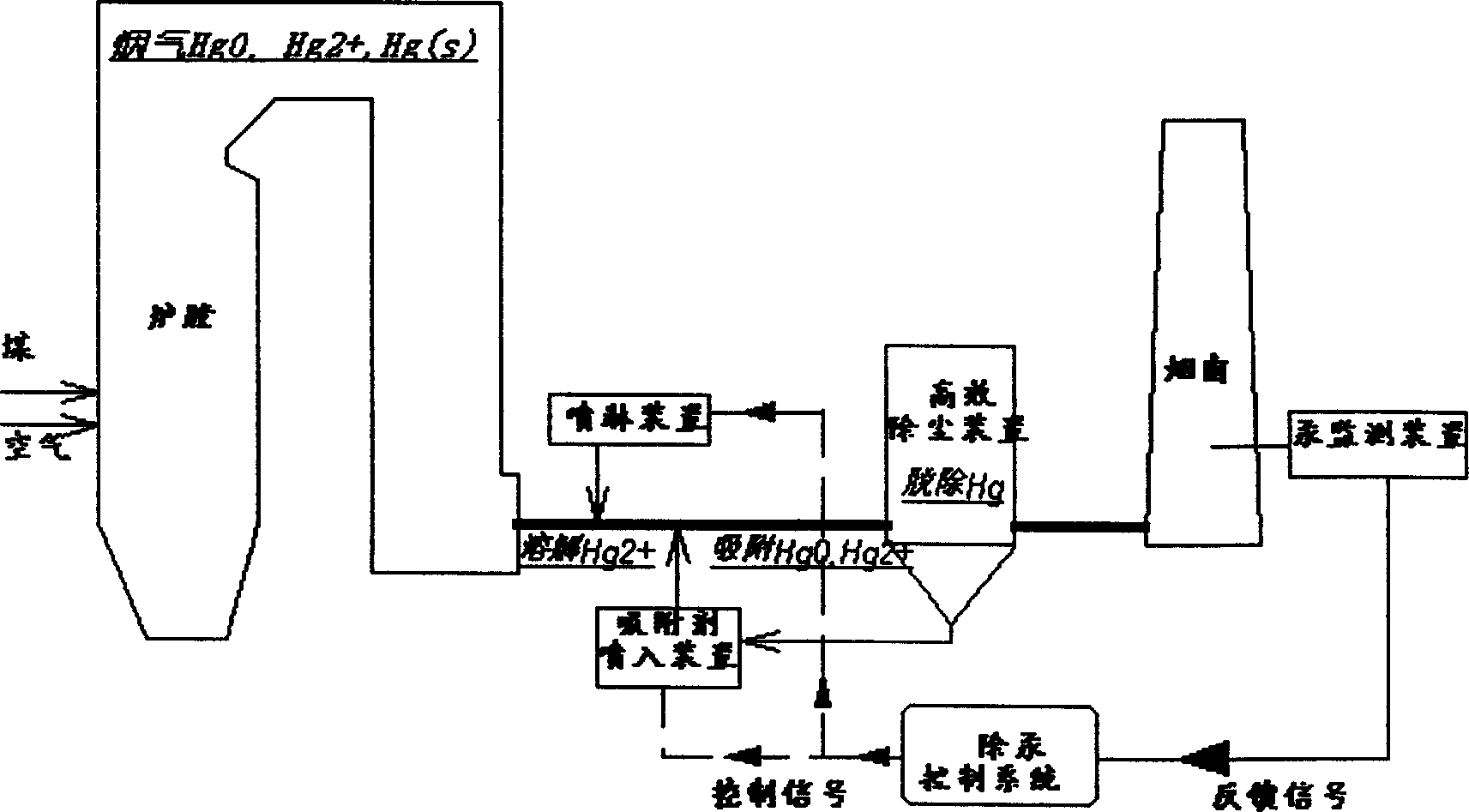

[0052] Such as figure 2 shown, with figure 1 Compared with not spraying additives. For a coal-fired boiler, the flue gas output is about 6×10 5 N m 3 / h, the total mercury content in the flue gas produced is about 3.8μg / Nm 3 . When the flue gas temperature is 150°C, spray a solution containing 0.2% chlorine water into the flue gas through the spraying device, and the liquid flow rate is 400Kg / h, and the ratio of elemental mercury to mercuric chloride or mercuric oxide is increased to 86%. , while the temperature of the flue gas is reduced to 100 degrees; then the MnO 2 Impregnated modified activated carbon adsorbent, sprayed at a rate of C / Hg 12000, to convert elemental mercury into Hg 2 MnO 2 This adsorption process is a relatively strong chemical adsorption process, and a new compound Hg is generated after adsorption. 2 MnO 2 :

[0053]

[0054] Mercury is in a low-valence state in this compound, and electrons are transferred from mercury to manganese insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com