Dry-process flue gas desulfurizing method using oscillating-nozzle feed

A technology of dry flue gas desulfurization and swinging nozzles, which is applied in the field of dry desulfurization system and fluidized dry flue gas desulfurization, which can solve the problems of affecting reaction efficiency and low concentration, so as to reduce water consumption and improve space Utilization, benefit to desulfurization or effect on digestion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

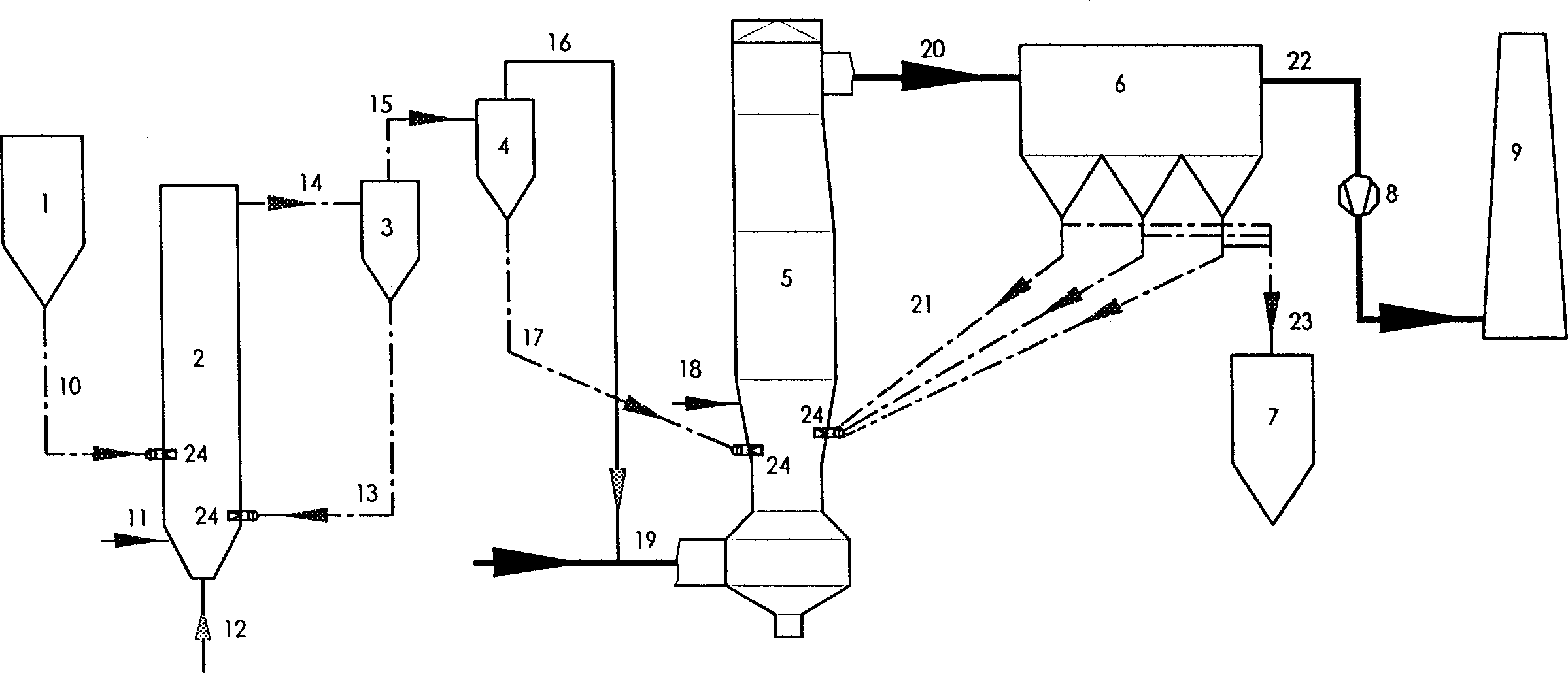

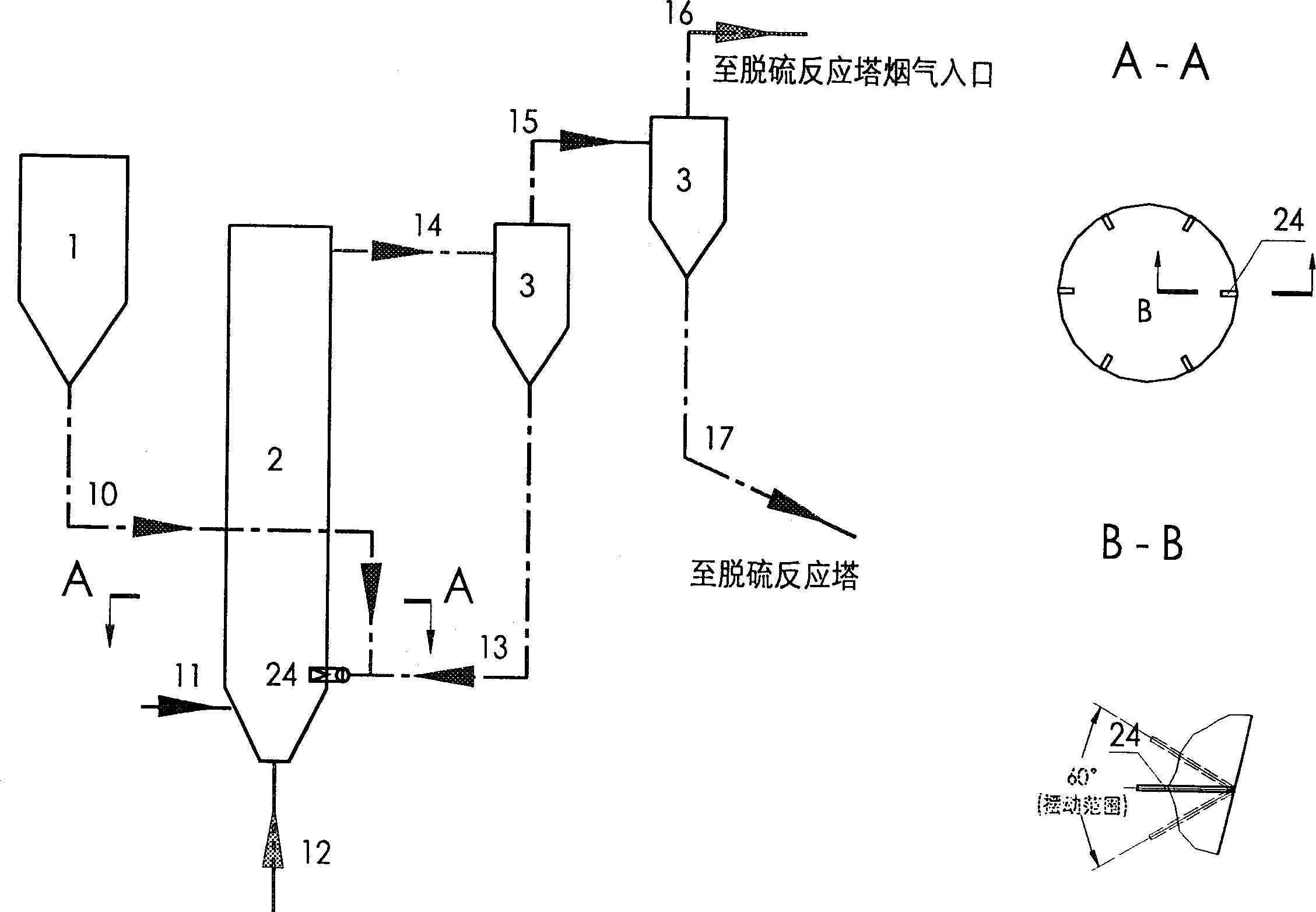

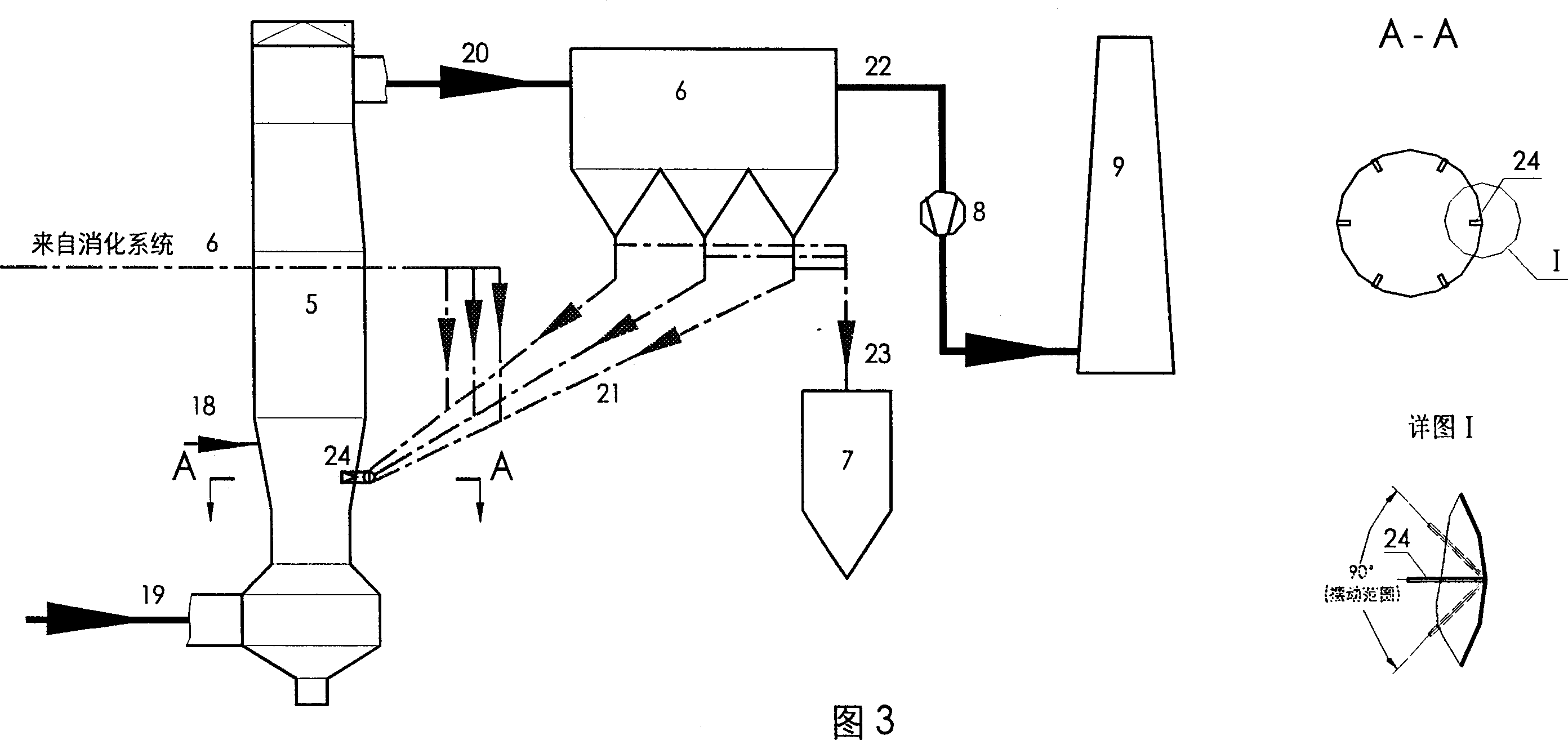

[0020] The present invention can be applied separately or in combination in the accompanying figure 1 In the desulfurization system shown:

[0021] 1) The desulfurization reaction technology of swing nozzle feeding is adopted.

[0022] Attached below figure 1 The embodiment, technological process and system arrangement structure of the present invention are described in detail.

[0023] Fluidized dry flue gas desulfurization reaction steps of materials fed into the swing nozzle: it feeds slaked lime or recycled materials through the swing nozzle in the desulfurization tower; The nozzle method is used to feed into the desulfurization tower; or the swing nozzle is used to feed the quicklime CaO or the circulating material in the digestion tower; or the quicklime and the circulating material (quicklime and slaked lime Ca(OH) 2 The mixture) is mixed and fed into the digestion tower by means of a swing nozzle.

[0024] Firstly, CaO powder, the raw material of the desulfurizer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com