A kind of heat insulation material containing anti-radiation agent with gradient distribution and its preparation method and application

A technology of anti-radiation agent and thermal insulation material, which is applied in textiles, papermaking, fiber processing, etc., can solve the problems of restricting high-temperature thermal insulation efficiency, uneven distribution of anti-radiation agent, and reducing the anti-radiation efficiency of anti-radiation structure. , to achieve the effect of improving high temperature insulation efficiency, excellent integrity, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

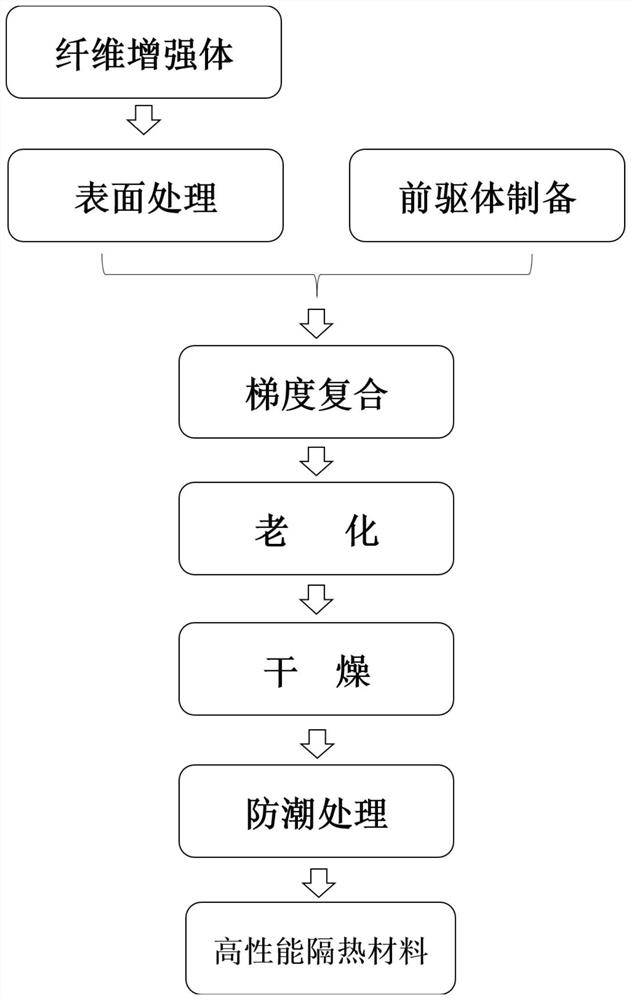

[0019] In a first aspect, the present invention provides a method for preparing a heat insulating material containing a gradient distribution anti-radiation agent, the method comprising the following steps:

[0020] (1) Surface treatment: use a composite sol containing silica and alumina to adjust the reactivity of the surface groups of the fiber reinforcement, and then use a silane coupling agent to adjust the fiber surface polarity of the fiber reinforcement;

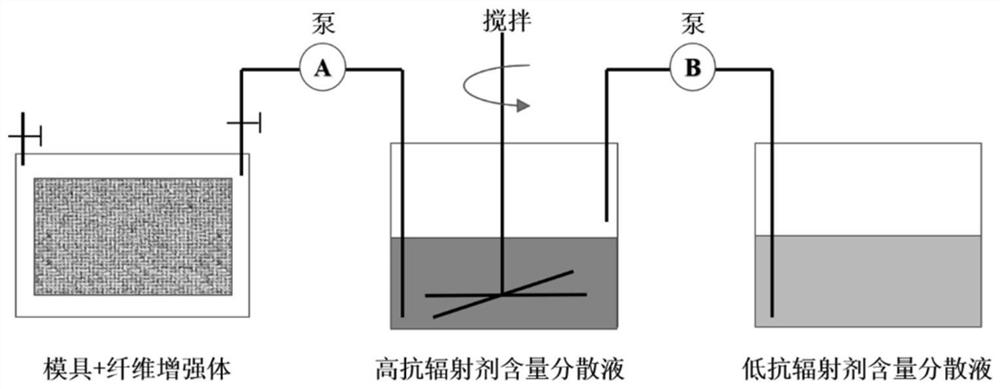

[0021] (2) Precursor dispersion preparation: disperse antiradiation agent in silica sol precursor, obtain the first dispersion liquid (ie low antiradiation agent content dispersion liquid) with the first antiradiation agent concentration and have the second antiradiation agent Concentration of the second dispersion liquid (i.e. high anti-radiation agent content dispersion liquid), the concentration of the first anti-radiation agent is lower than the concentration of the second anti-radiation agent; then to the first di...

Embodiment 1

[0067] The size is 500mm×500mm×25mm, the density is 0.1g / cm 3 A piece of commercially available quartz fiber felt with room temperature thermal conductivity of 0.03W / (m K) is placed in a container, and a mass fraction of 10 % silica / alumina sol solution, and immerse the fiber mat, keep it for 5 to 10 minutes, take out the fiber mat and dry it, after heat treatment at 100°C-1h / 200°C-1h / 300°C-1h figure 1 In the mold in, the mold size is 550mm×550mm×30mm.

[0068] Add rutile titanium dioxide with a particle size of 4 μm to the commercially available silica hydrosol with a solid content of 20%, and the dosages are 5% and 50% of the mass of the sol, respectively, to form A liquid and B liquid correspondingly. Add polyethylene glycol with a molecular weight of 1000 to liquid A and liquid B respectively, in an amount of 0.1% by mass of rutile titanium dioxide. The pH of the system was controlled at about 6 by adding concentrated hydrochloric acid dropwise, and the two systems were ...

Embodiment 2

[0071] The size is 500mm×500mm×25mm, the density is 0.1g / cm 3 , a piece of commercially available quartz fiber felt with room temperature thermal conductivity of 0.03W / (m K) is placed in a container, and a mass fraction of 10 % silica / alumina sol solution, and immerse the fiber mat, keep it for 5 to 10 minutes, take out the fiber mat and dry it, after heat treatment at 100°C-1h / 200°C-1h / 300°C-1h figure 1 In the mold in, the mold size is 550mm×550mm×30mm.

[0072] Add silicon carbide with a particle size of 4 μm to the commercially available silica hydrosol with a solid content of 20%, and the dosages are 5% and 40% of the mass of the sol, respectively, to form A liquid and B liquid correspondingly. Add polyethylene glycol with a molecular weight of 1000 to liquid A and liquid B respectively, in an amount of 0.1% by mass of rutile titanium dioxide. The pH of the system was controlled at about 6 by adding concentrated hydrochloric acid dropwise, and the two systems were stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com