Ultrasonic cleaner for hollow fibre separating membrane

A fiber separation and cleaning device technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of shortened chemical cleaning cycle, unsatisfactory cleaning effect, and huge equipment, etc., to achieve excellent Cleaning effect, environmental protection effect is good, the effect of equipment simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

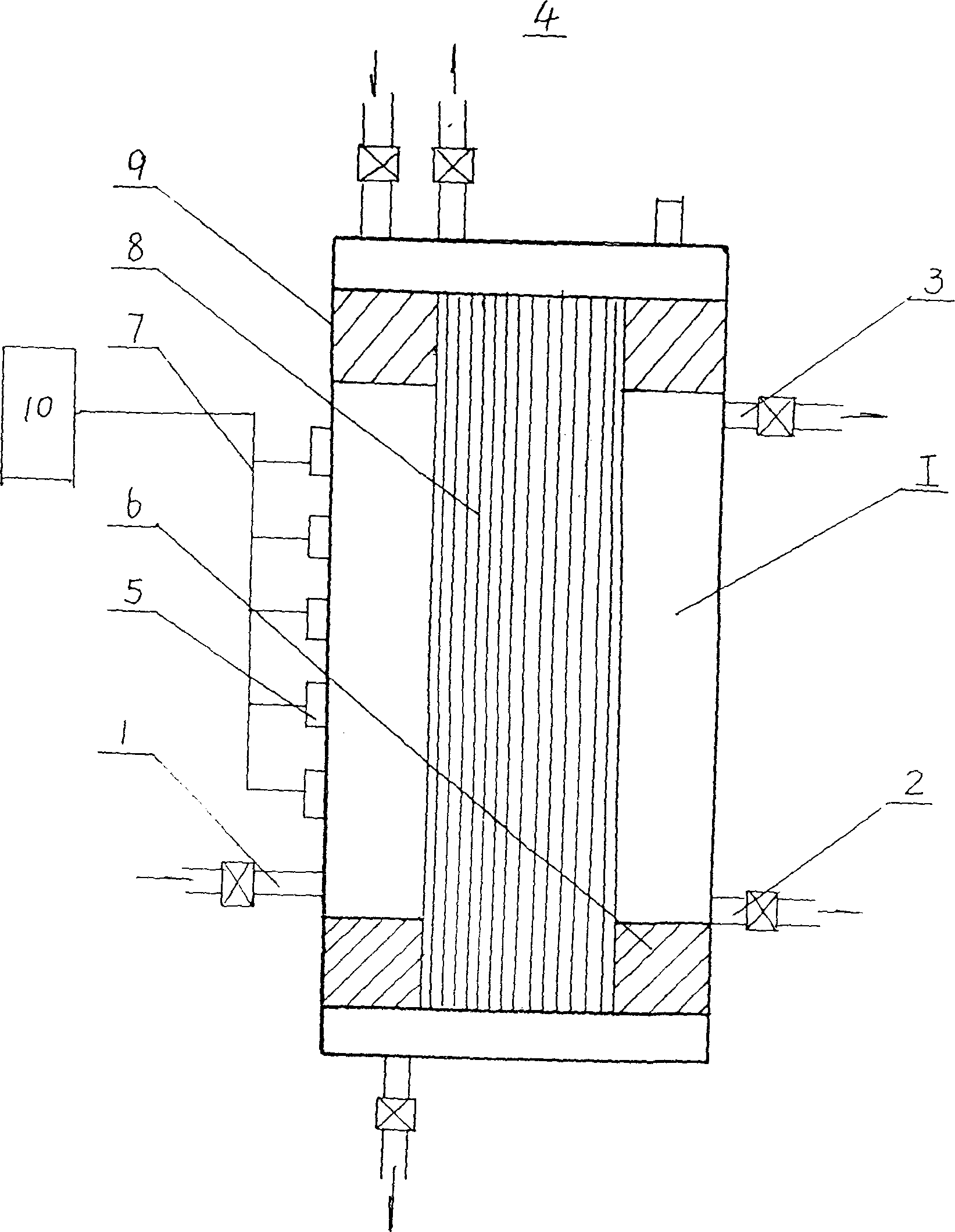

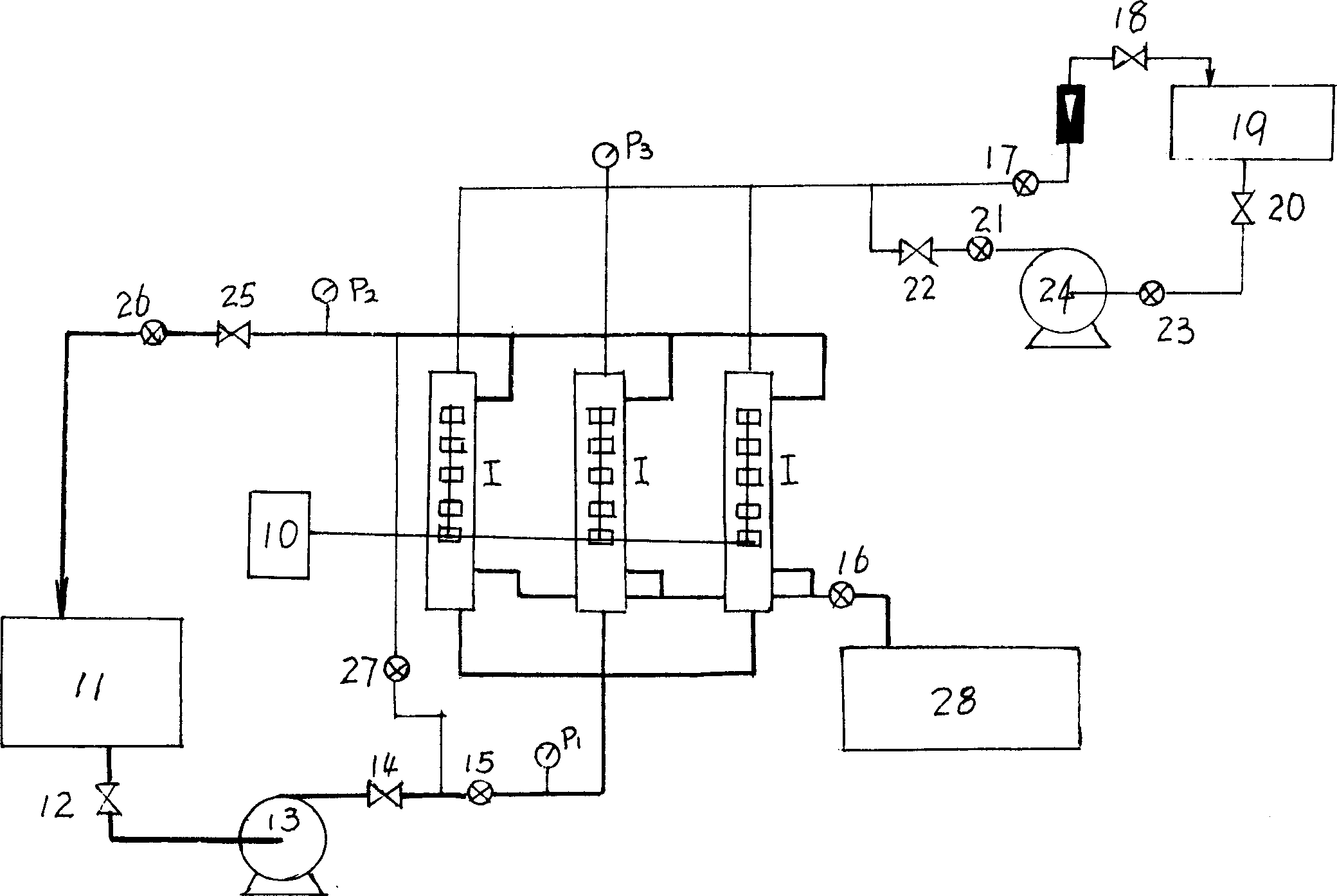

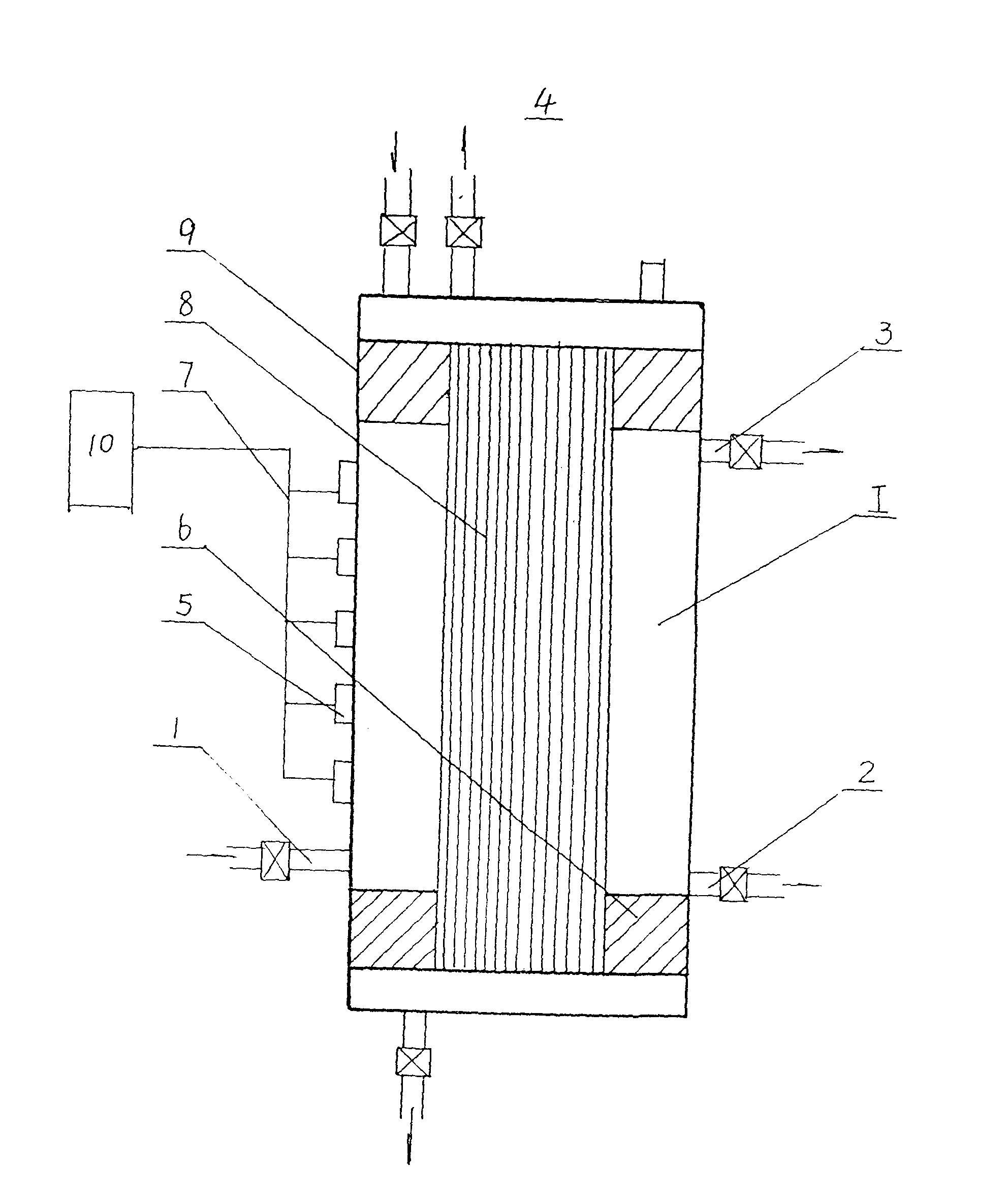

[0011] Such as figure 1 Shown: in the device of the present invention, there are water inlets 1 and sewage outlets 2 at different heights relative to the lower part of the hollow fiber separation membrane module 1, there are circulating water outlets 3 and water outlets 4 above the module 1, and the middle of the module 1 is equipped with five An ultrasonic energy exchanger 5 is fixed on the stainless steel shell 9 surface of assembly 1 with glue or magnet, and this shell 9 also can adopt other metal materials such as aluminum and aluminum alloy, because metal material is beneficial to the propagation of ultrasonic wave, in addition, in order to make reflection The wave effect is better, and the shape of its shell 9 mostly adopts a symmetrical geometric polyhedron (tetrahedron, hexahedron, octahedron). The present embodiment adopts a hexahedron, and the ultrasonic energy exchanger 5 and the ultrasonic energy generator 10 are connected together with the cable 7, and the separati...

Embodiment 2

[0013] Embodiment 2: five ultrasonic energy exchangers 5 are sealed and fixed on the bar steel by embedding, and then the bar steel is fixed on the inner side of the shell 9 of the hollow fiber separation membrane module 1. At this time, the shell 9 is not limited by the material. Can be non-metallic material. Other principles and structures are exactly the same as in Embodiment 1.

[0014] The invention can also be used for ultrasonic cleaning of biofilters and biofilter beds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com