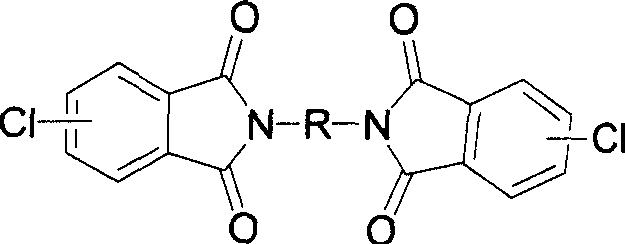

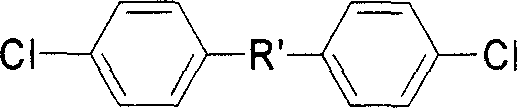

Synthesis method of polysulfone-polyimid copolymer

A technology of polyimide copolymer and diphthalimide, which is applied in the field of synthesis of polysulfone-polyimide copolymer, can solve the problems of harsh reaction conditions, low yield, difficult separation and purification, etc., and achieve reduction The effect of dosage, improvement of performance and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

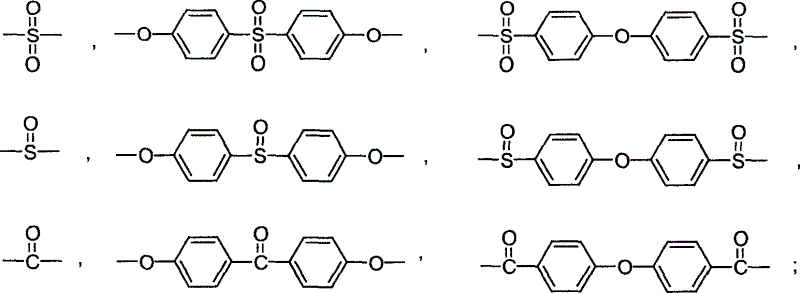

Method used

Image

Examples

Embodiment 1

[0024] Add 5mmol of nickel bromide, 20mmol of triphenylphosphine and 150mmol of zinc powder into the reaction flask, fill with nitrogen to remove oxygen, add 25ml of DMAc, and stir the reaction at 120°C. After the system turns reddish brown, add 150ml of DMAc and 25mmol of di (4-(4-Chlorophthalimido)phenyl) ether and 25mmol dichlorodiphenyl sulfone were reacted for 8h, then the reactant was poured into 1000ml 25% HCl / ethanol solution, stirred for 30min, Filter, reflux the precipitate with 500ml of ethanol for 8h, filter, and dry at 100°C to obtain 16.2g of product with a yield of 96%. Mix cresol as a solvent, and measure the inherent viscosity at 30°C to be 0.21dl / g.

Embodiment 2

[0026] Add 5mmol of nickel bromide, 60mmol of triphenylphosphine and 200mmol of zinc powder into the reaction flask, fill with nitrogen to remove oxygen, add 30ml of DMAc, and stir the reaction at 90°C. After the system turns reddish brown, add 120ml of DMAc and 25mmol of di (4-(3-Chlorophthalimido)phenyl) ether and 25mmol dichlorodiphenyl sulfone were reacted for 5h, then the reactant was poured into 1000ml 25% HCl / ethanol solution, stirred for 20min, Filter, reflux the precipitate with 300ml of ethanol for 6h, filter, and dry at 100°C to obtain 16.0g of product with a yield of 95%. Mix cresol as a solvent, and measure the inherent viscosity at 30°C to be 0.16dl / g.

Embodiment 3

[0028] Add 5mmol of nickel bromide, 50mmol of triphenylphosphine and 280mmol of zinc powder into the reaction flask, fill with nitrogen to deoxygenate, add 40ml of DMAc, and stir the reaction at 60°C. After the system turns reddish brown, add 620ml of DMAc and 25mmol of di (4-(4-chlorophthalimido)phenyl)methane and 25mmol dichlorobenzophenone were reacted for 3h, then the reactant was poured into 1000ml 25% HCl / ethanol solution, stirred for 40min, Filtrate, reflux the precipitate with 500ml of ethanol for 6h, filter, and dry at 100°C to obtain 16.5g of product with a yield of 98%, mixed with cresol as a solvent, and an inherent viscosity at 30°C of 0.2dl / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inherent viscosity | aaaaa | aaaaa |

| Inherent viscosity | aaaaa | aaaaa |

| Inherent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com