Conductive roller and image-forming apparatus having conductive roller

A conductive roller, conductive technology, applied in the direction of corona discharge device, conductive material dispersed in non-conductive inorganic material, equipment of electric recording process using charge pattern, etc., can solve the difficulty of disposal and can not be reduced Problems such as the sum of the ratio, the resistance resistance voltage dependence and the resistance environment dependence reduction, achieve the effect of excellent environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

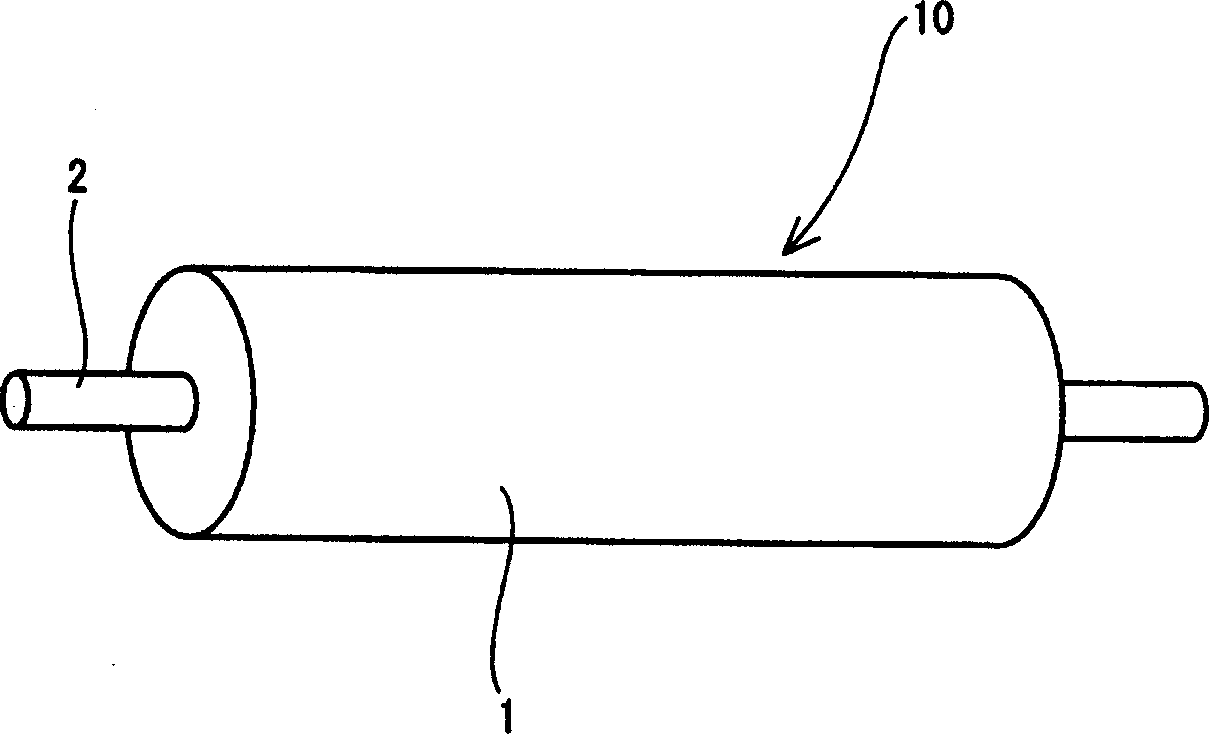

[0137] The conductive elastic layer is formed using a polymer composition containing a non-chlorine and non-bromine-based polymer as a main component and containing a salt of an anion having a fluorine group and a sulfonyl group. As the non-chlorine and non-bromine-based polymer, NBR, which is a polymer having a cyano group, and, if necessary, ethylene oxide-propylene oxide-allyl glycidyl ether copolymer (EO), which is a polyether polymer, are used. :PO:AGE=90:4:6) and EPDM as a low-polarity ozone-resistant rubber. As a salt of an anion having a fluorine group and a sulfonyl group, lithium-bis(trifluoromethanesulfonyl)imide was used. In addition, as lithium-bis(trifluoromethanesulfonyl)imide, a product synthesized by a conventionally known method described in Japanese Patent Laid-Open No. 2001-288193 and the like is used. In addition, the salt of the anion having a fluorine group and a sulfonyl group is not compounded through a medium composed of a low molecular weight polyet...

Embodiment 6~ Embodiment 17

[0190] The salt of an anion having a fluorine group and a sulfonyl group is mixed into 100 parts by weight of a mixture (mixed rubber) of EPDM and NBR in an amount of 0.01 to 20 parts by weight, ADCA or / and OBSH are used as chemical foaming agents, and The foaming aid is foamed using urea as necessary to obtain the conductive foamed roller of the present invention.

Embodiment 18~ Embodiment 21

[0232] In a mixed rubber in which NBR, EPDM, and EO-PO-AGE copolymer with an acrylonitrile content of 18% are blended in each predetermined weight ratio, a salt having an anion containing a fluorine group and a sulfonyl group is dispersed in a predetermined weight ratio. The rubber composition was foamed with a chemical foaming agent, and each was made into a conductive roller.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com