Cadmium sulfide nanometer particle sensitizing agent, preparation method and uses thereof

A technology of nano-particles and cadmium sulfide, which is applied in emulsified silver emulsions, etc., can solve the problems of reduced probability of latent image formation, dispersion, and difficulty in increasing the sensitivity, so as to reduce fog, increase sensitivity, and reduce latent image dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of sensitizer: In a 2.5L glass container, add 0.7L of distilled water and 20g of gelatin, dissolve it under stirring at 50°C, then add 0.31g of Cd(NO 3 ) 2 4H 2 O to dissolve and stir well; add 0.24 g of Na to 0.3 L of distilled water 2 S·9H 2 O is made into a solution, and slowly added to the above-mentioned solution stirred in a constant temperature water bath at 50°C and stirred at a high speed, and then stirred for 5 minutes after adding, to prepare a cadmium sulfide nanoparticle sensitizer with a particle size of 1 to 30 nanometers .

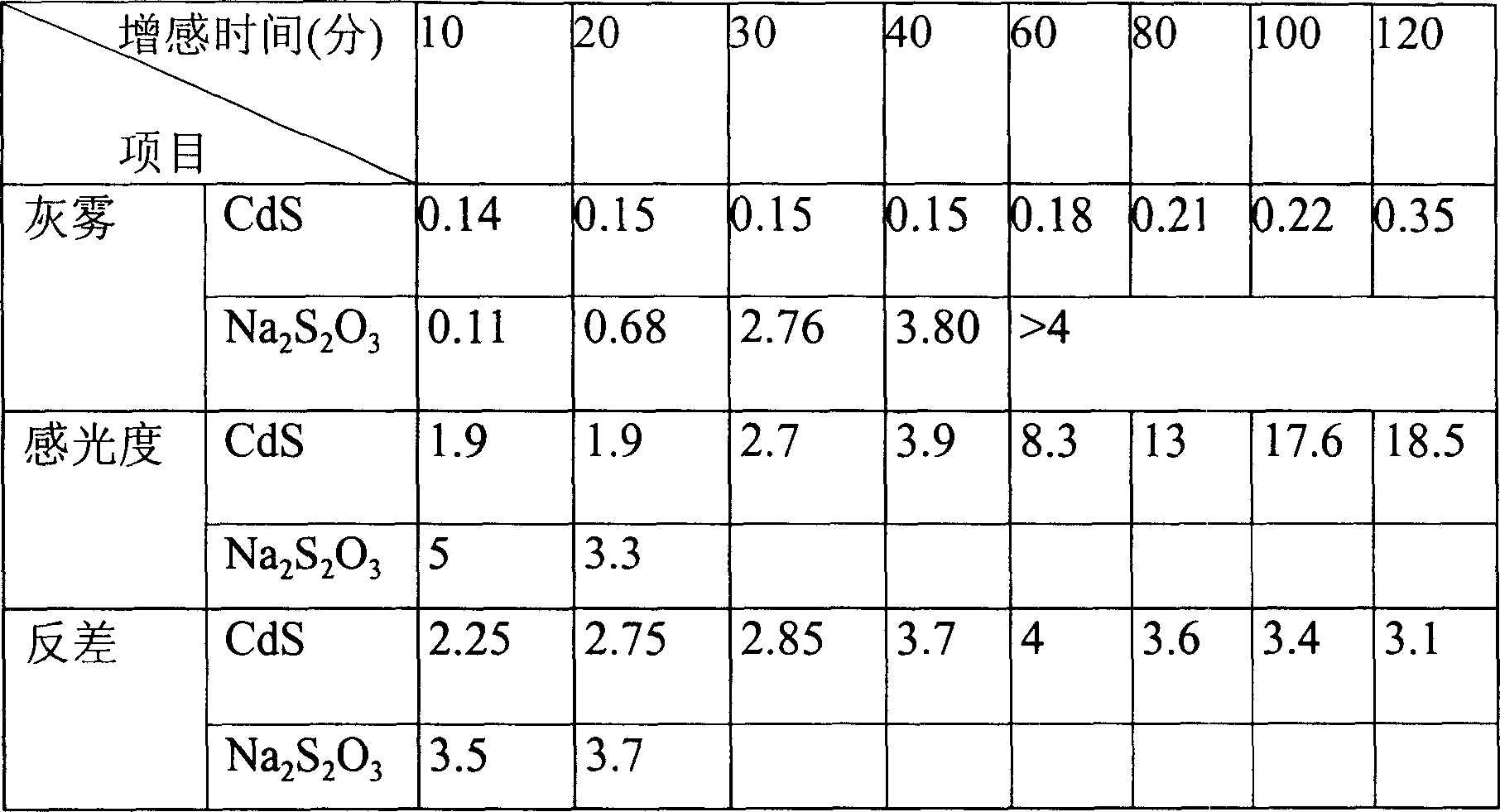

[0043] Preparation of cubic silver bromide microcrystalline emulsion: In a 50-liter container equipped with a high-speed stirring device, add 10 liters of water, 0.2 kg of gelatin, and 0.0011 kg of potassium bromide in advance, heat to 60 ° C, stir at constant temperature, and control pAg at about 7.5 , within 300 minutes, 2 liters of 3.0 mol / liter silver nitrate aqueous solution and 2 liters of 3.0 mol / liter potassiu...

Embodiment 2

[0046] The cadmium sulfide nanoparticle sensitizer of Example 1 was used.

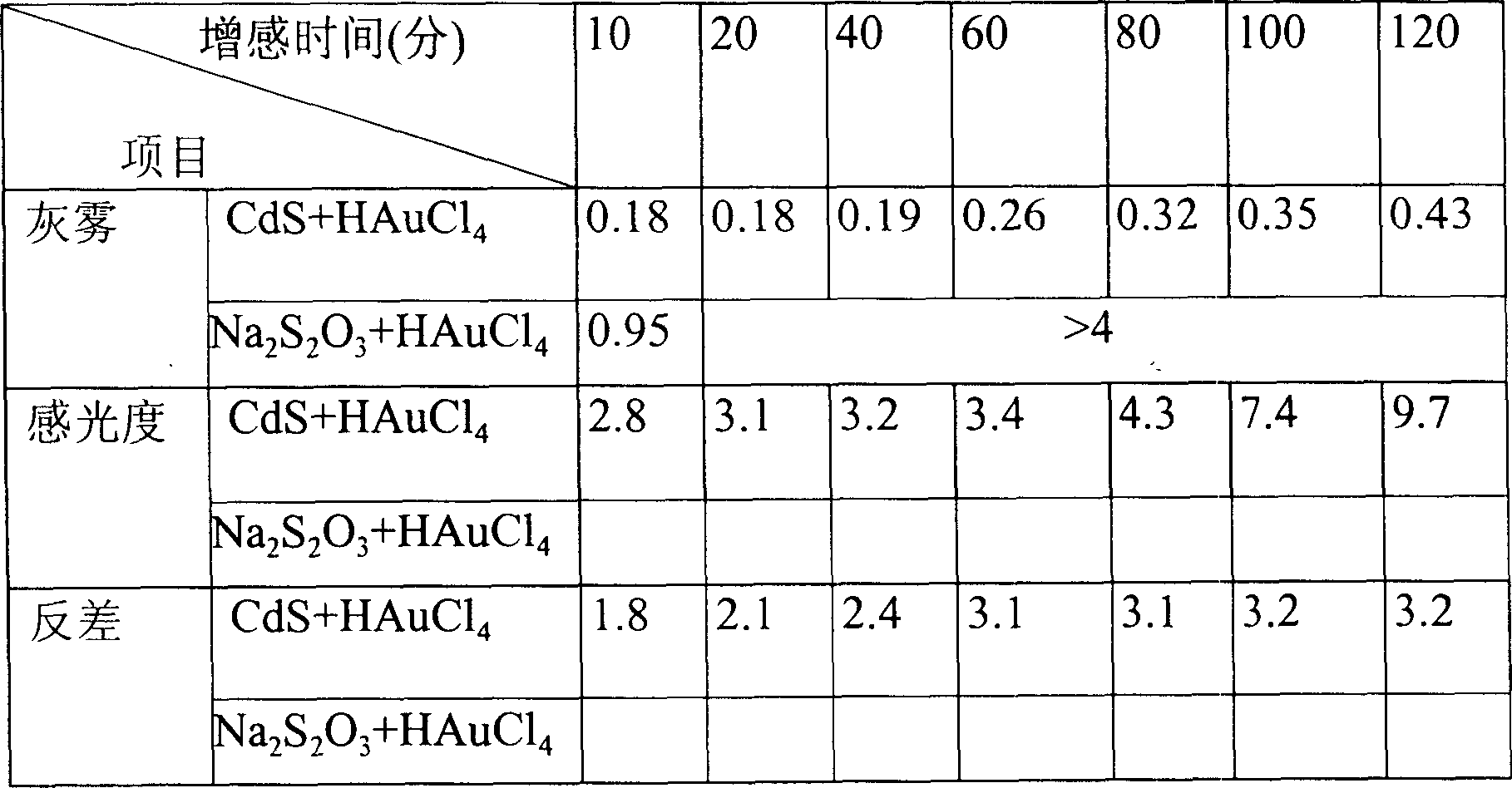

[0047] Sulfur-gold synergistic sensitization of cubic silver bromide microcrystalline emulsion: Accurately weigh two parts of 1 kg of cubic silver bromide emulsion, add them to two 1.5L containers respectively and let them melt; and accurately measure the above-mentioned preparation 20mL of cadmium sulfide nanoparticle sensitizer, added to one of the containers containing the emulsion, and then measured 1 × 10 -4 Add 10mL of moL / L gold trichloride hydrochloride solution into the emulsion; accurately measure 20mL of pre-configured 0.001mol / L sodium thiosulfate, add it to another container containing the emulsion, and then Measure 1×10 -4 Add 10 mL of moL / L gold trichloride hydrochloride solution to the emulsion. Carry out chemical sensitization in a constant temperature water bath at 65°C, and then coat the emulsion on the polyester film base at different time intervals, the amount of silver coated is...

Embodiment 3

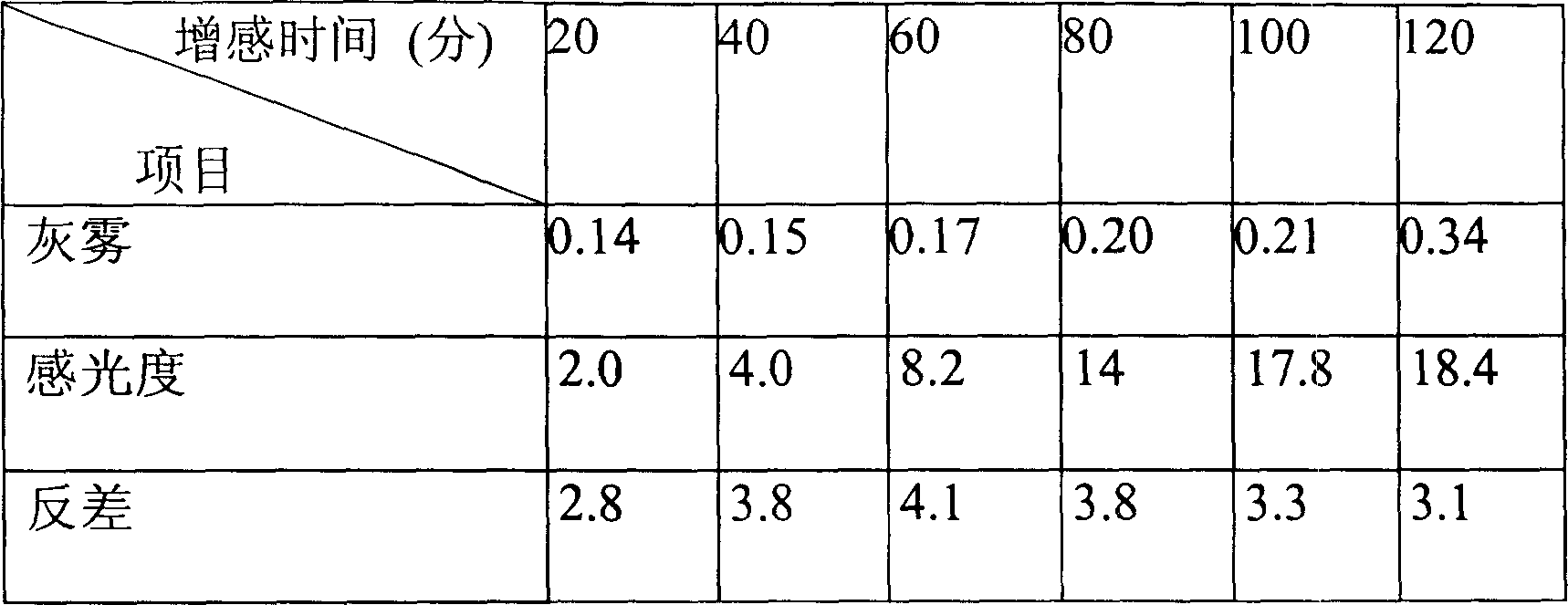

[0049] The cadmium sulfide nanoparticle sensitizer of Example 1 was used.

[0050] Sensitize cubic silver bromide microcrystalline emulsion at different temperatures: Accurately weigh two parts of 1 kg of cubic silver bromide microcrystalline emulsion, add them to two 1.5L containers and place them in 65°C and 75°C containers respectively. Melt it in a constant temperature water bath; accurately measure two parts of the cadmium sulfide nano-particle sensitizer 20mL prepared above, add to two containers containing the emulsion respectively and carry out chemical sensitization for 80 minutes; then apply the emulsion on the On the polyester film base, the amount of silver coated is 0.012 kg / square meter, cooled, dried at room temperature, exposed with a special exposure instrument, developed, fixed, dried, and tested. The obtained results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com