Hair conditioning composition containing film forming gradient copolymer, airsol composition containing the same hair care composition and treatment method

A technology of gradient copolymer and composition, applied in the field of hair cosmetic composition, can solve the problems of high polydispersity, composition layering, insolubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

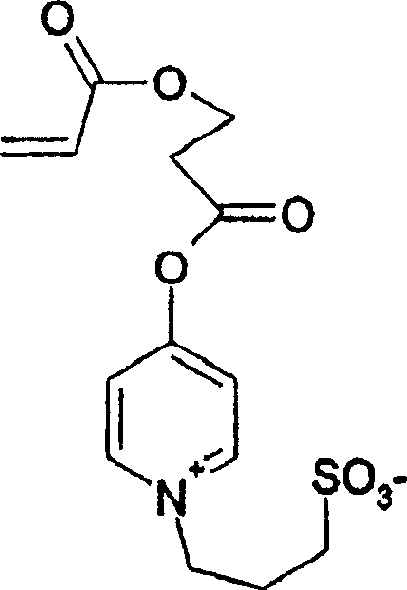

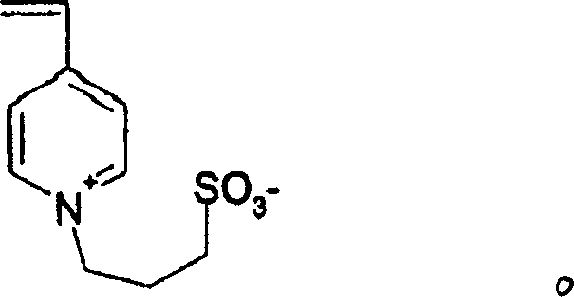

[0357] Embodiment 1: the bulk synthesis of gradient copolymer

[0358] The reactant mixture is as follows:

[0359] -MONAMS: 3.0g

[0360] -SG1: 0.18g

[0361] - Ethyl acrylate: 480 g i.e. 80% by weight / total monomer weight

[0362] - Styrene: 60 g i.e. 10% by weight / total monomer weight

[0363] -Methacrylic acid: 60 g i.e. 10% by weight / total monomer weight

[0364] All ingredients were mixed together under nitrogen atmosphere without adding solvent, then it was heated and kept at temperature 110-115° C. for 198 min. The reaction was terminated when the conversion reached 60%.

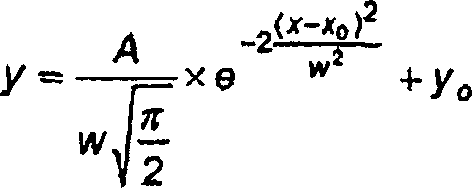

[0365] Gradients were calculated by the simulation method, and the curves shown below were obtained. Theoretical predictions indicated a 30% incorporation of the mixture (styrene / methacrylic acid) and 70% ethyl acrylate.

[0366] The reliability of the model was verified by monitoring the relative concentrations of the three monomers by gas chromatography and polymer NMR analysis.

[0367] W...

Embodiment 2

[0378] Example 2: Bulk synthesis of gradient copolymers

[0379] Following the individual steps described in Example 1, various copolymers were prepared from the following reactant mixtures:

[0380] -MONAMS: 3.0g

[0381] -SG1: 0.18g

[0382] - Styrene: 60g

[0383] -Methacrylic acid: 60g

[0384]

Embodiment 3

[0385] Embodiment 3: Carry out synthesis in the presence of solvent

[0386] Synthesis was carried out as in Example 1 except that solvent was present. The reactant mixture is as follows:

[0387] -MONAMS: 3.43g

[0388] -SG1: 0.2g

[0389] - Ethyl acrylate: 336g

[0390] - Styrene: 42g

[0391] -Methacrylic acid: 42g

[0392] -Toluene: 180g

[0393] All ingredients were mixed together in toluene as solvent under nitrogen atmosphere, then it was heated and kept at temperature 110-115° C. for 198 min.

[0394] The final conversion was 82%, while the obtained solids content was 57.2% by weight.

[0395] The following analysis results were obtained:

[0396] Mn = 30570 g / mol, Mw = 50500 g / mol and Ip = 1.65. The composition dispersity (or w) was 2.0.

[0397] The final composition of the copolymer was analyzed by liquid adsorption chromatography (LAC), and the results showed that it was similar in composition to the copolymer prepared in Example 1, and there was no hom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com