In-situ analysis method of propylene ammoxidizing product

A technology of oxidation reaction and analysis method, which is used in the preparation of hydrocarbon ammoxidation, analysis of materials, material separation, etc., can solve the problems of inability to realize automatic operation of the device, long analysis time, high labor intensity, etc., and achieve easy automation and good technical effect. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

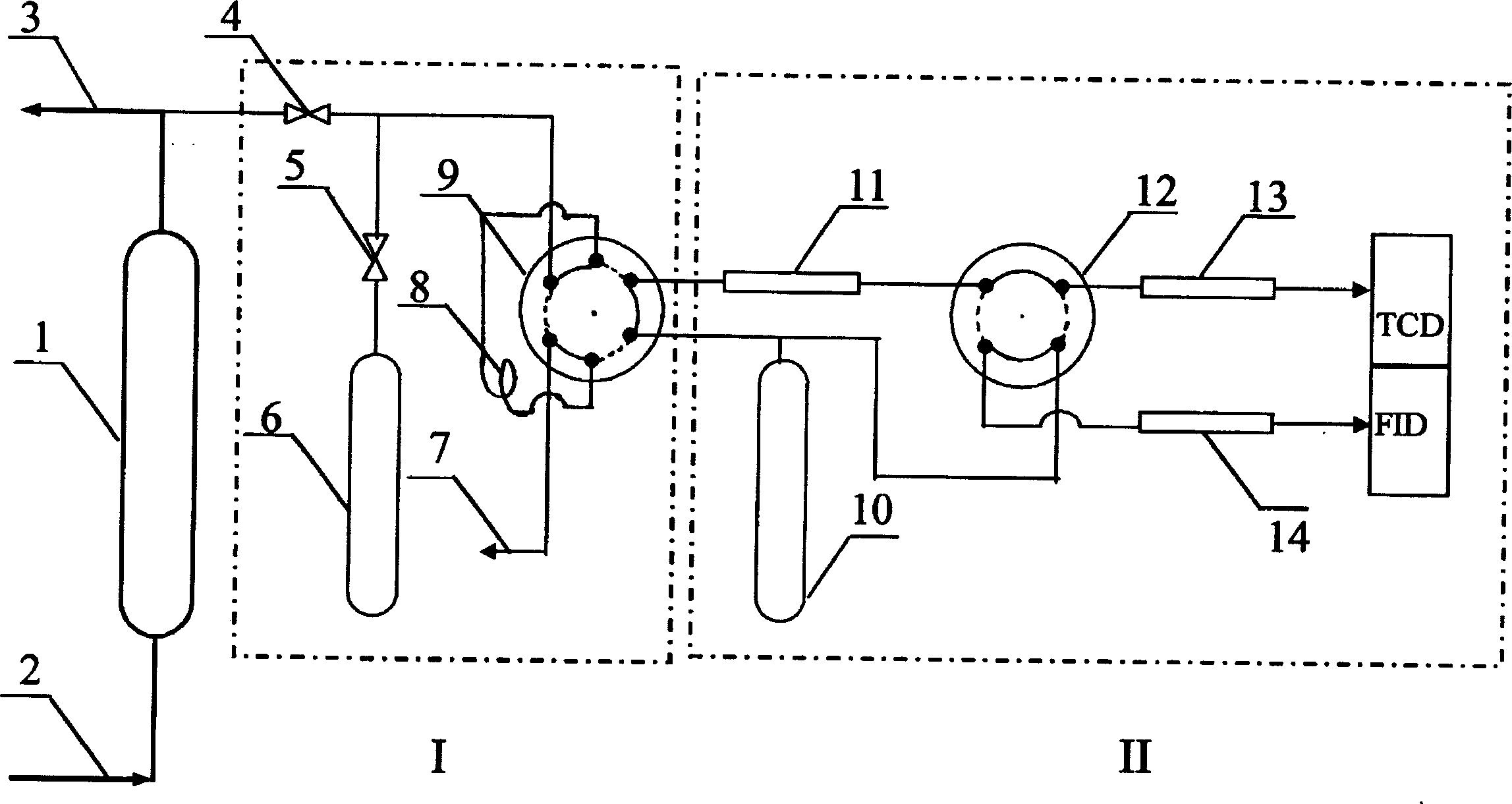

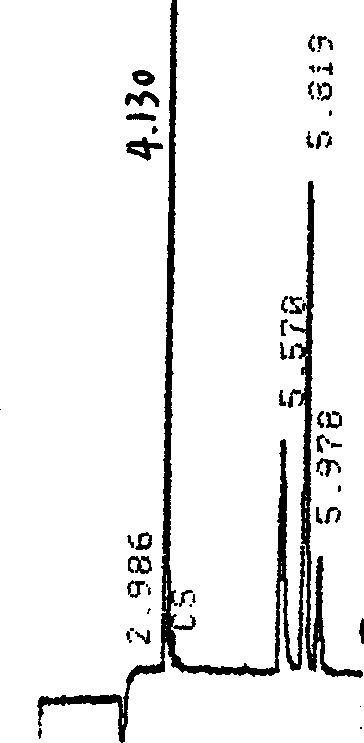

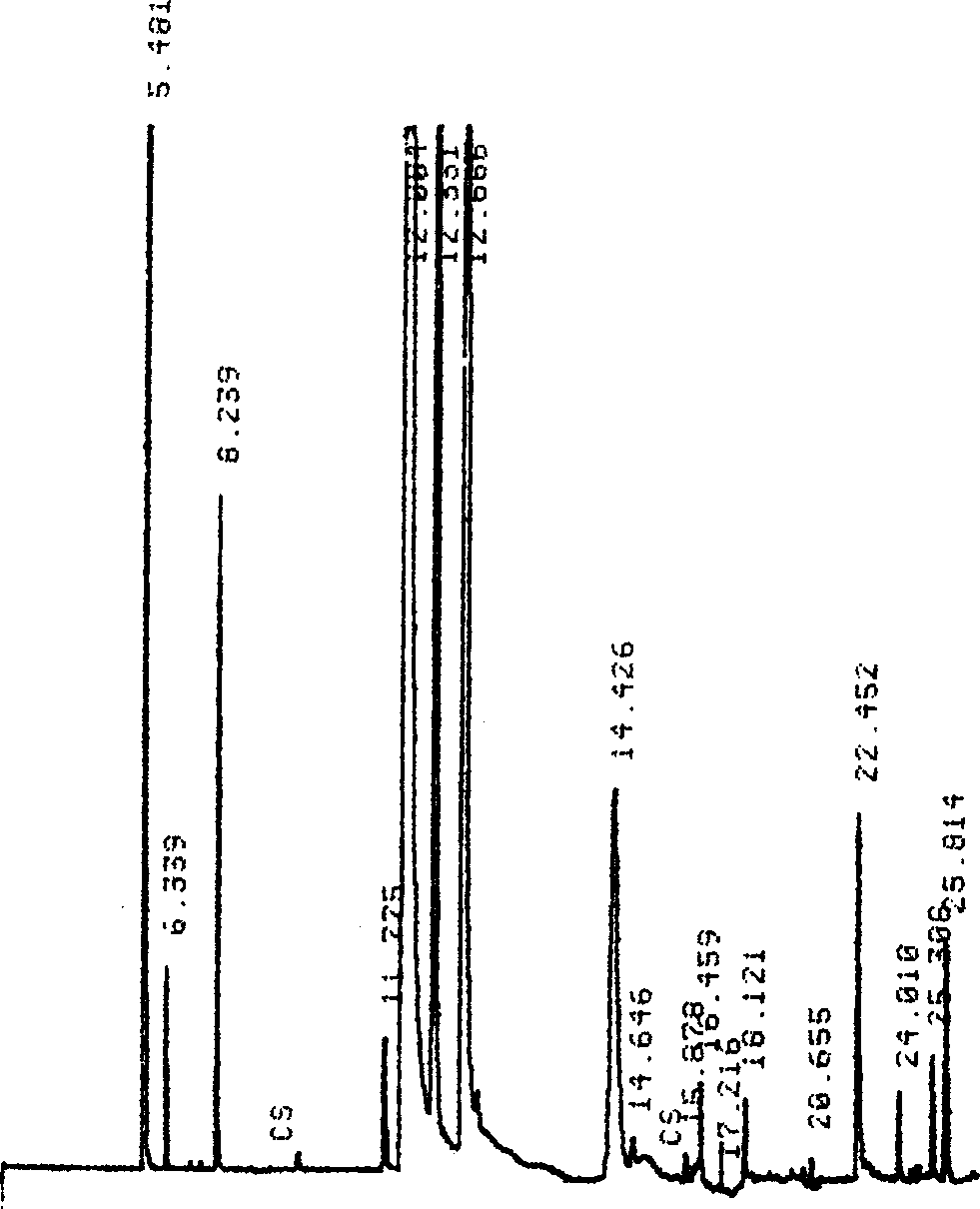

[0023] Refer to attached figure 1 , the gas chromatograph used is HP4890D, equipped with double valves, two detectors of TCD and FID, and two capillary inlets to provide two paths of carrier gas. The carrier gas is high purity He. Chromatographic column 11 is WAX 30m×0.32mm×0.25 micron, chromatographic column 13 is Pora-PLOT Amines 25m×0.32mm×10 micron, and chromatographic column 14 is FFAP 50m×0.32mm×0.50 micron. When installing the above process, the appropriate capillary column and valve connection method should be adopted to minimize the dead volume of the system.

[0024] The chromatographic conditions are as follows:

[0025] Column head pressure A (with four-way valve 12): 87KPa;

[0026] Column head pressure B (with six-way valve 9): 145KPa;

[0027] TCD: temperature, 250°C; auxiliary gas flow, 3.4ml; reference gas flow, 15.0ml;

[0028] FID: temperature, 250°C; auxiliary gas flow, 19.0ml; air flow, 350ml; hydrogen flow, 20.5ml;

[0029] Capillary split injector,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com