Super-resolution glass slide/cover glass and method of obtaining super spatial resolution

A super-resolution and cover glass technology, applied in microscopes, optics, instruments, etc., can solve the problems of high price, limited application, complicated operation, etc., and achieve the effect of rapid observation and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

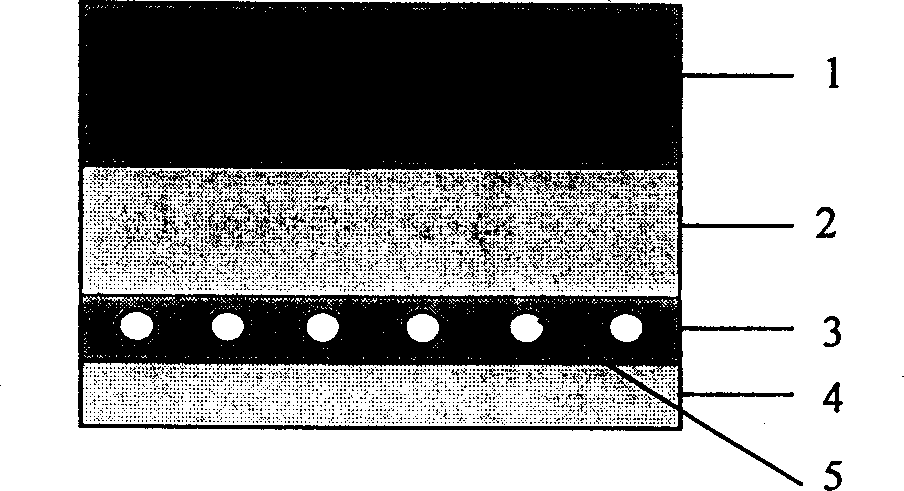

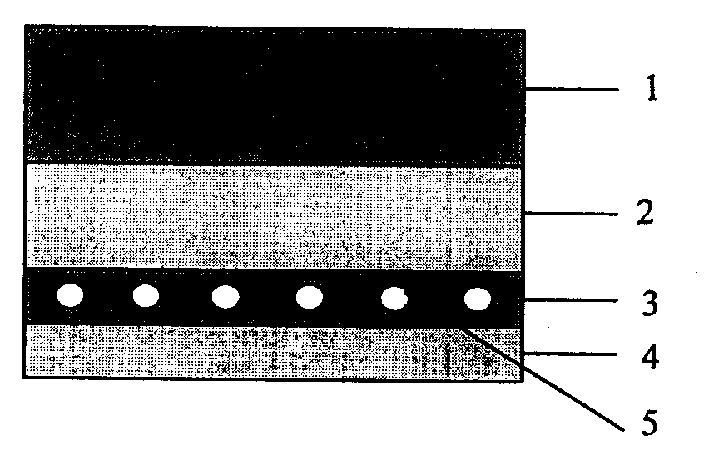

[0020] The super-resolution slide / cover glass structure is shown in Figure 1, which is fabricated by conventional vacuum sputtering technology. The optical nonlinear layer is a 15nm-thick gold (Au) particle film, which functions as a fiber optic probe with nanometer-scale optical apertures in near-field optical microscopy. Dielectric protection outer layer is 40nm thick ZnS-SiO 2 (ZnS and SiO 2 The chemical ratio is 1:1) dielectric film, which is equivalent to the method of controlling the distance between the fiber optic probe and the sample surface in the near-field range in the near-field optical microscope. The dielectric protection inner layer is 170nm thick ZnS-SiO 2 (ZnS and SiO 2 The chemical ratio is 1:1) dielectric film, and the substrate is a common slide / cover glass. The sample to be observed (100nm polystyrene polymer beads) is placed on the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com