Recovery method of heavily polluated substance produced during production of foaming agent and device

A technology of ADC foaming agent and recovery method, which is applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the serious pollution of ADC foaming agent, achieve good economic and social benefits, and eliminate Effects of contamination, ease of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

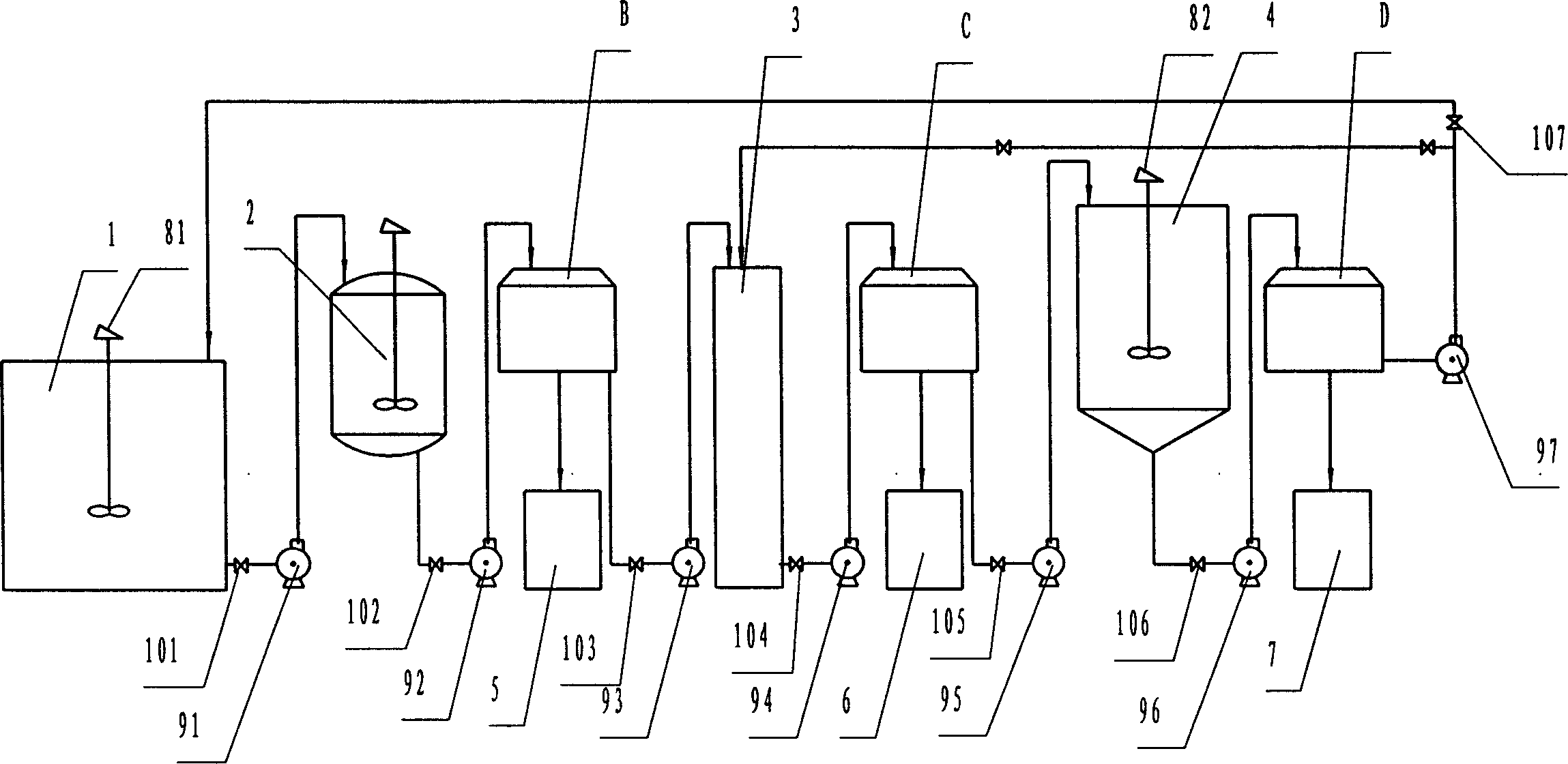

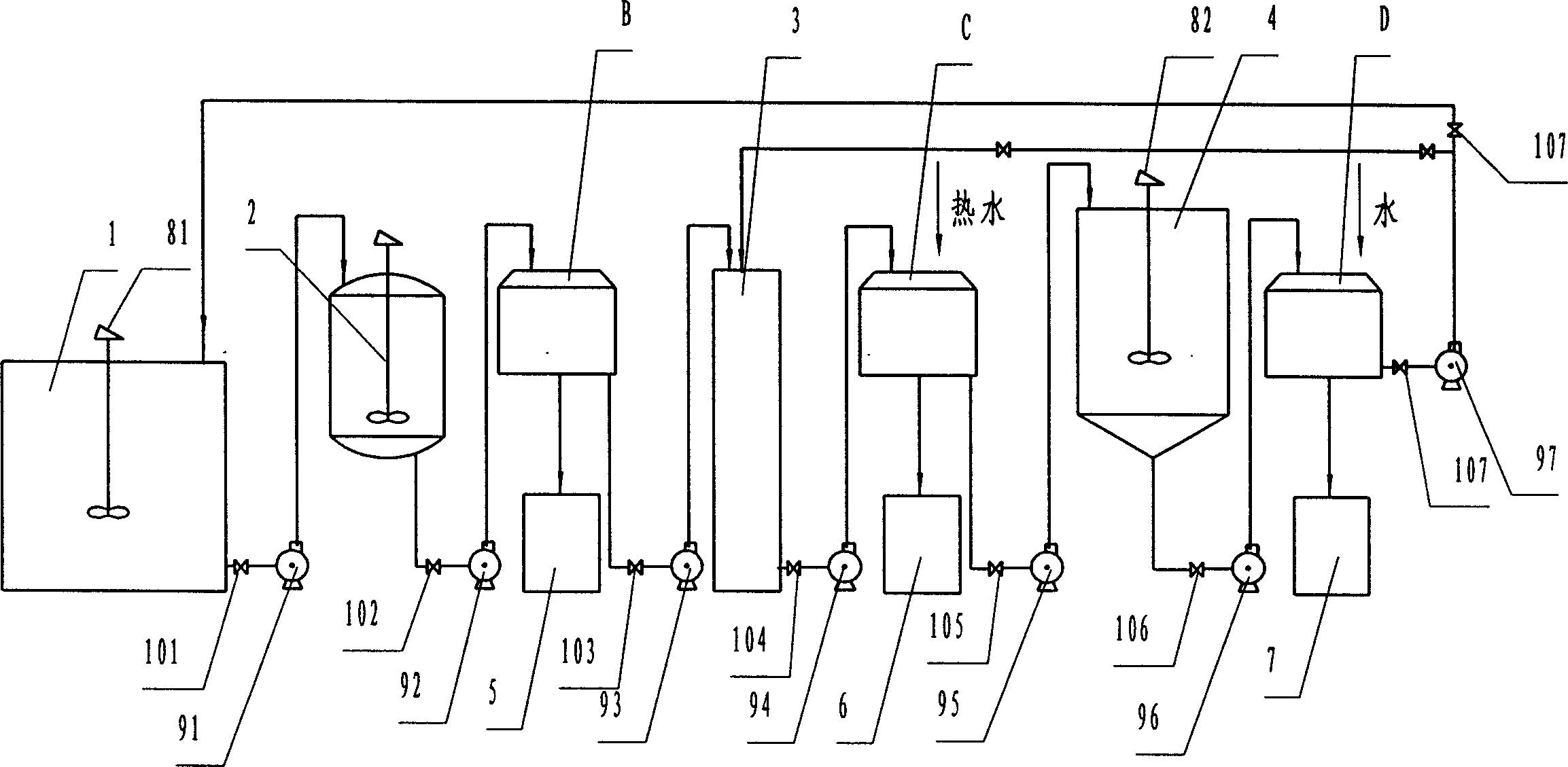

[0101] Such as figure 2 The recovery method of pollutants in the production process of the shown ADC blowing agent,

[0102]1. When the evaporation method reclaims sodium chloride, a large amount of sodium chloride crystallizes out when the volume of the first filtrate decreases by 60% in the evaporation tank 3, and the ammonium chloride is nearly saturated. Import the centrifuge for centrifugation, and open the centrifuge C, cut 104, Feed pump 94, carry out drying and dehydration, when the second filter cake sodium chloride accounts for centrifuge C capacity 70~80%, stop feed pump 94, cut off 104, use hot water in centrifuge C to second filter cake Wash until the ammonium chloride content of the second filter cake is lower than 0.05%, stop the centrifuge C, and go out the second filter cake to the sodium chloride storage tank 6;

[0103] 2. When freezing and reclaiming ammonium chloride, the temperature of the second filtrate in the freezing pot 4 is imported to a centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com