Method of preparing calcium propionate using egg shell

A calcium propionate, egg shell technology, applied in the field of chemical treatment, can solve the problems of destroying the natural activity of egg shells, polluting the environment, high energy consumption, etc., and achieving the effects of avoiding environmental pollution, high reaction yield and solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

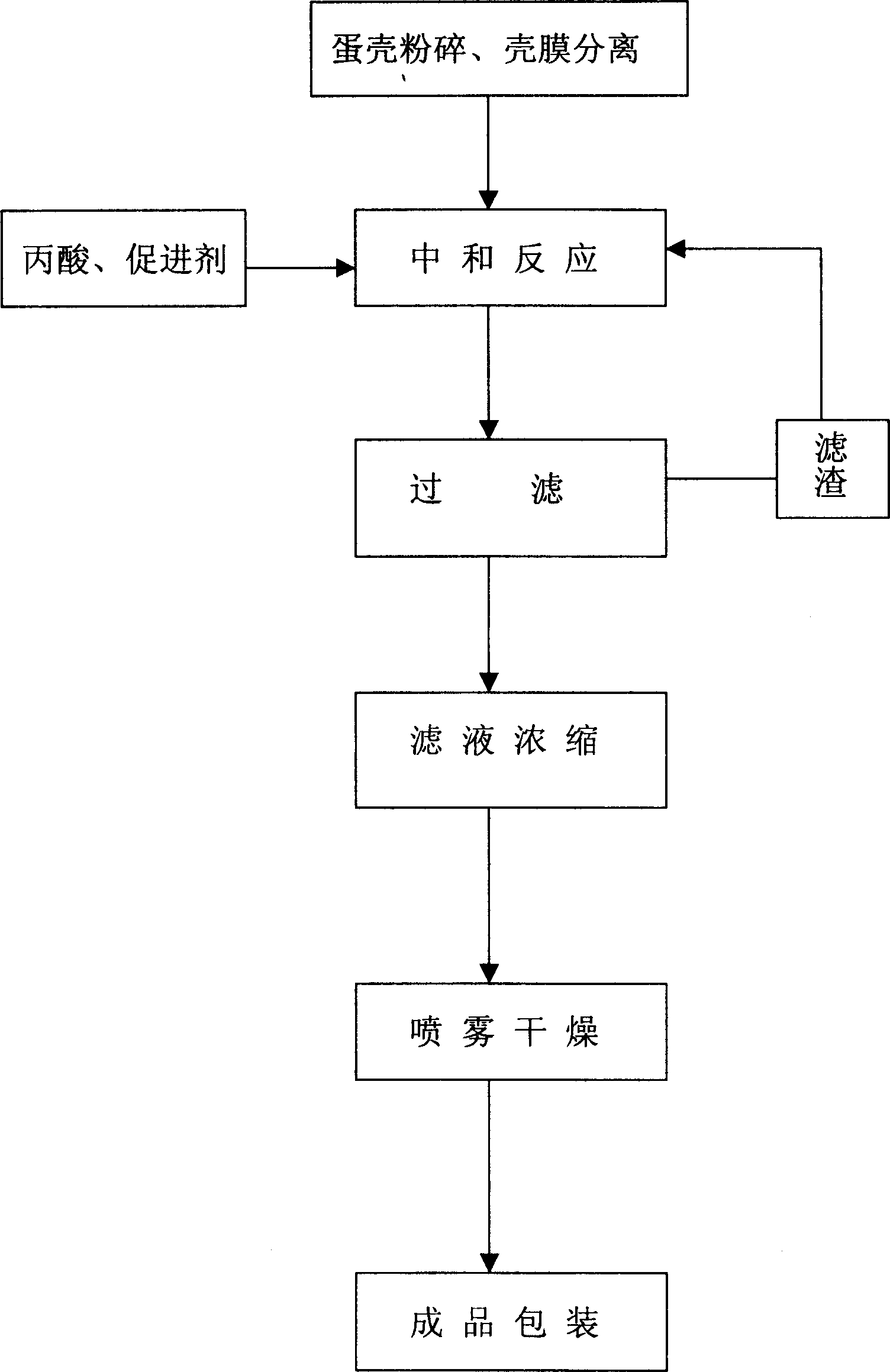

Image

Examples

Embodiment 1

[0031] Embodiment 1: This embodiment is the preferred embodiment

[0032] (1) shell membrane separation

[0033] The eggshells are roughly crushed with a roller-type pulverizer with a blower, and the shells and membranes are completely separated, and the egg membranes are used for other purposes. After the membranes are separated, the shells are pulverized with a mill-type pulverizer to a fineness of 0.125mm;

[0034] (2) Neutralization reaction

[0035] at 3.0M 3 Put 2.3T of water into the reaction pot, start the agitator to stir, the stirring speed is 100 rpm, add 145kg of eggshell powder under constant stirring, and then add 175k9 industrial propionic acid for neutralization reaction, after 3 hours of reaction Add Ca(OH) 2 , CaO and NaOH, when adjusting the pH value of the reaction system to 13.0, continue to react for half an hour;

[0036] (3) filter

[0037] The materials that have completed the reaction are pumped into a plate-and-frame filter press for filtration,...

Embodiment 2

[0046] (1) shell membrane separation

[0047] The eggshells are roughly crushed with a roller-type pulverizer with blower, and the shells and membranes are completely separated, and the egg membranes are used for other purposes. After the membranes are separated, the shells are pulverized to a fineness of 0.140mm by a mill-type pulverizer;

[0048] (2) Neutralization reaction

[0049] at 3.0M 3 Put 2.5T of water into the reaction pot, start the stirrer to stir, the stirring speed is 120 rpm, add 142kg of eggshell powder under constant stirring, then add 180kg of industrial propionic acid for neutralization reaction, and react for 3.5h After adding Ca(OH) 2 , CaO and NaOH, when the pH value of the reaction system is adjusted to be greater than 13.0, the reaction is continued for one and a half hours;

[0050] (3) filtering is identical with embodiment 1;

[0051] (4) Concentration under reduced pressure

[0052] The filtered filtrate was adjusted to pH=8.0 with propionic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com