Electric double-layer capacitor

一种电双层电容、电容的技术,应用在双层电容器、电解电容器、电容器等方向,能够解决EDL电容比能降低、比能不足够高、成本高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

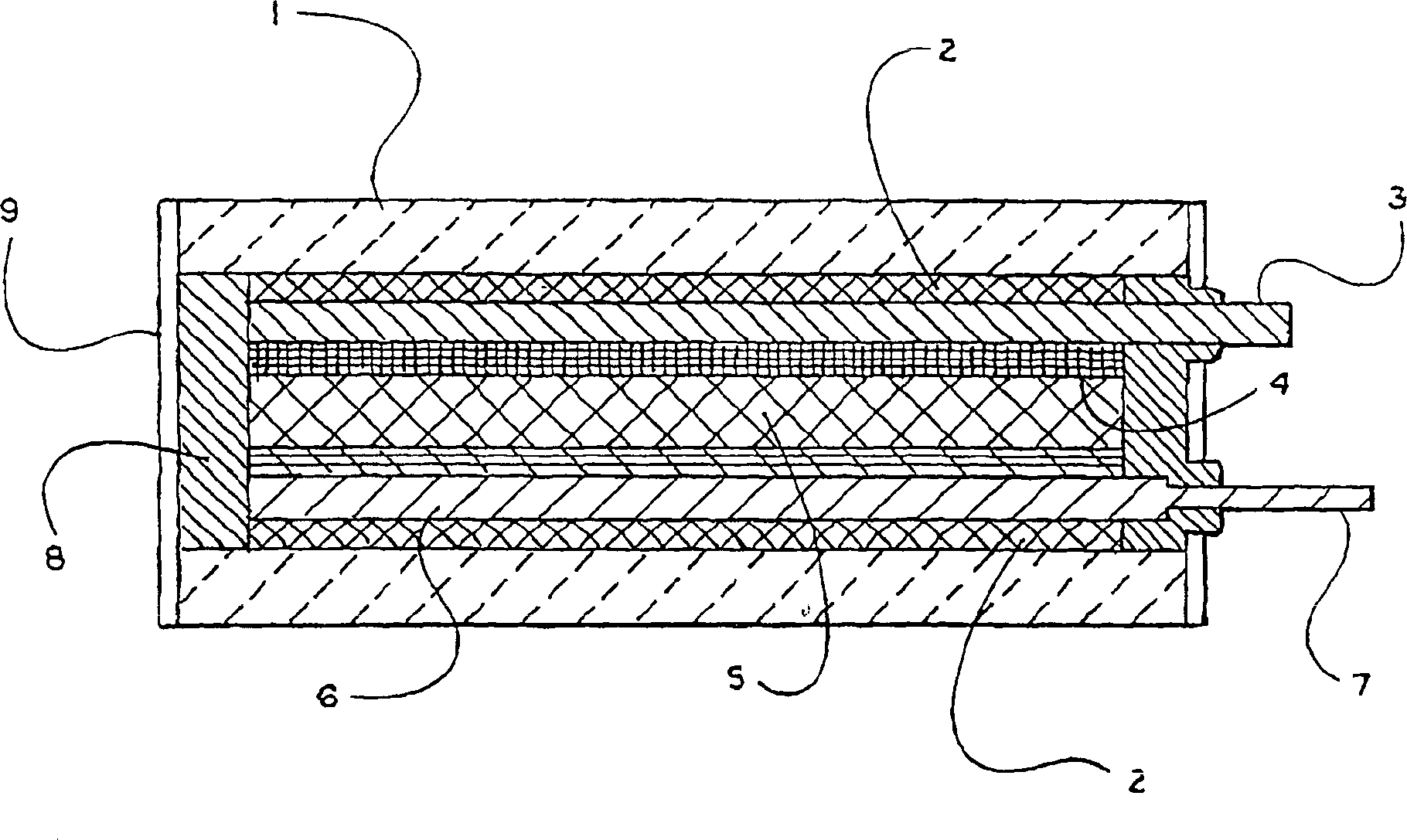

[0037] An electric double layer capacitor ( figure 1 ), comprising a negative electrode 5 in the form of 8 layers of activated carbon fibers of the TCA type, each layer having 1200m 2 / g specific surface area and 300 μm thickness; a 1-mm thick positive electrode 7 with an active mass comprising lead sulfate and lead dioxide pressed into an alloy comprising 94% lead and 5% antimony A Grace-type porous separator 6; a pressure shell 1 of the outer tube; an insulator 2 to prevent short circuits between capacitor electrodes; a current collector 3 made of iron sheets; a corrosion-resistant collector made of graphite flakes Electrical protection layer 4 ; acid-resistant sealing layer 8 ; and a pressure-resistant outer tube 9 .

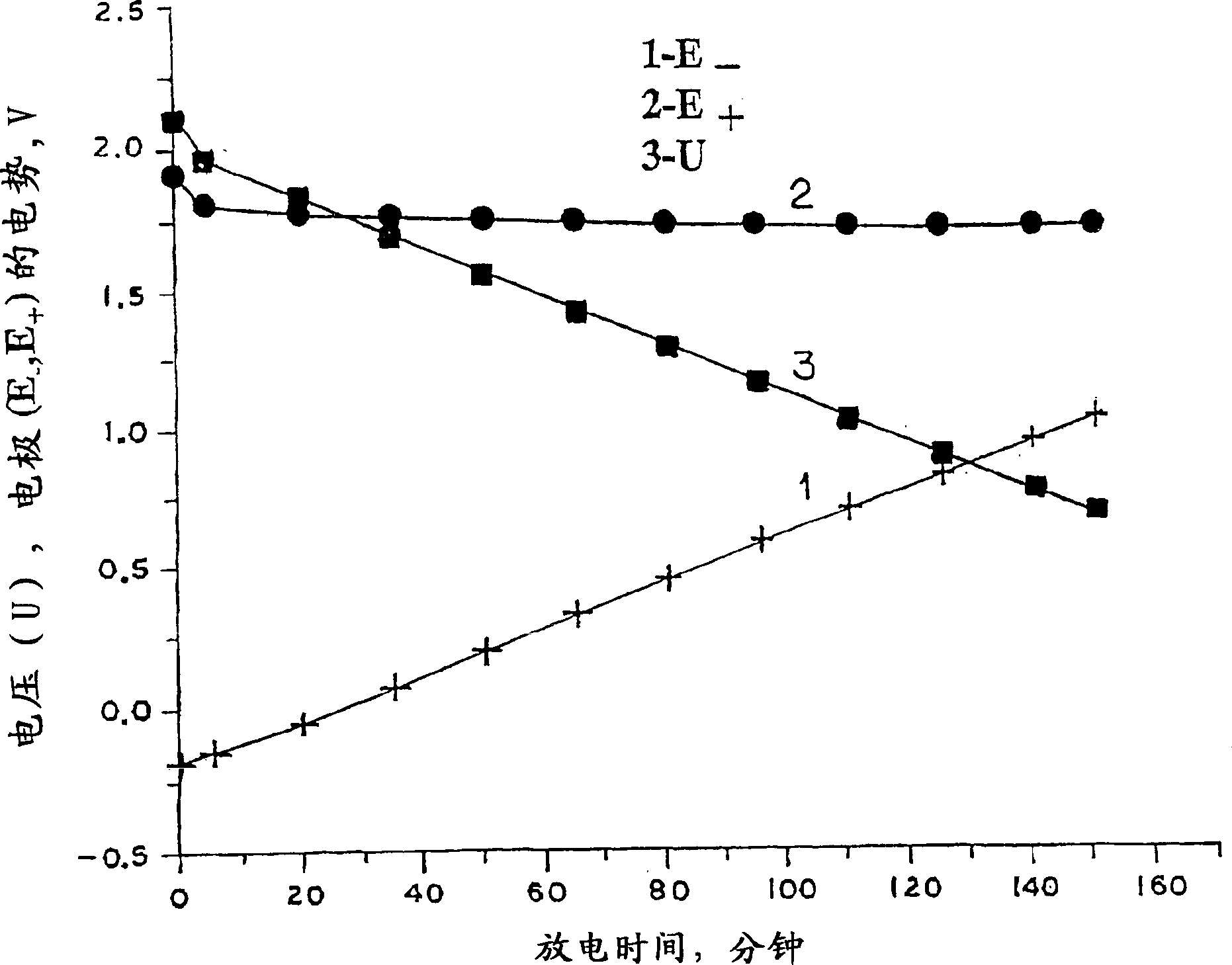

[0038] According to chemical analysis, the active mass of the positive electrode in the discharged state contains 91.2% PbSO 4 and 4.6% PbO 2 , while in the charged state it contains 3.2% PbSO 4 and 92.8% PbO 2 . Therefore, the mass ratio of lead sulfat...

example 2

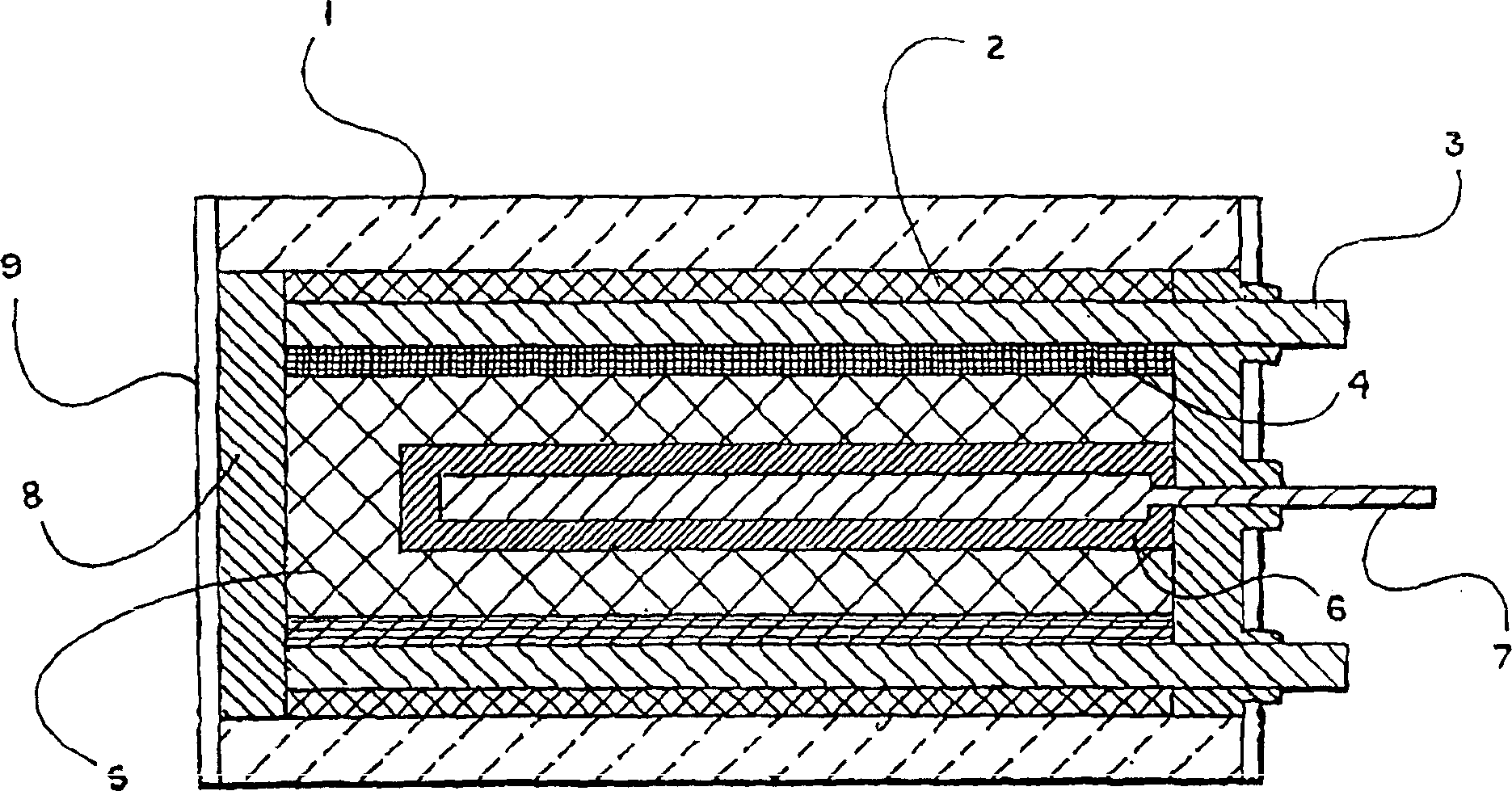

[0042] An electric double layer capacitor ( figure 2 ) and Example 1 ( figure 1 ) differs in that, in this case, two negative electrodes are used, each made of 4 layers of TCA-type activated carbon fibers (with 1200m 2 / g specific surface area and 300μm layer thickness), placed on both sides of the positive electrode and connected. The positive non-polarizable electrode 7 consists of a grid made of an alloy containing 94% lead and 5% antimony. A coating comprising 83% active mass and 17% Teflon was applied to the openings of the mesh. According to chemical analysis, the mass ratio of lead sulfate and lead dioxide at the device in the discharged state was 95.8%. In the fully charged state, this ratio is 5.6%, and in the 50% discharged state it is 45.1% (in this calculation, PbSO 4 and PbO 2 The total mass of is taken as 100%). A Grace type divider 5 is used. The current collector 3 is made of stainless steel sheet. The corrosion-resistant current collector protection l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com