Method for preparing nano bars of cadmiun sulfide

A technology of cadmium sulfide nanorods and sodium sulfide, which is applied in the directions of cadmium sulfide, nanostructure manufacturing, nanotechnology, etc., can solve a large number of, effective, low-cost and other problems, and achieves the effects of low cost, no environmental pollution, and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

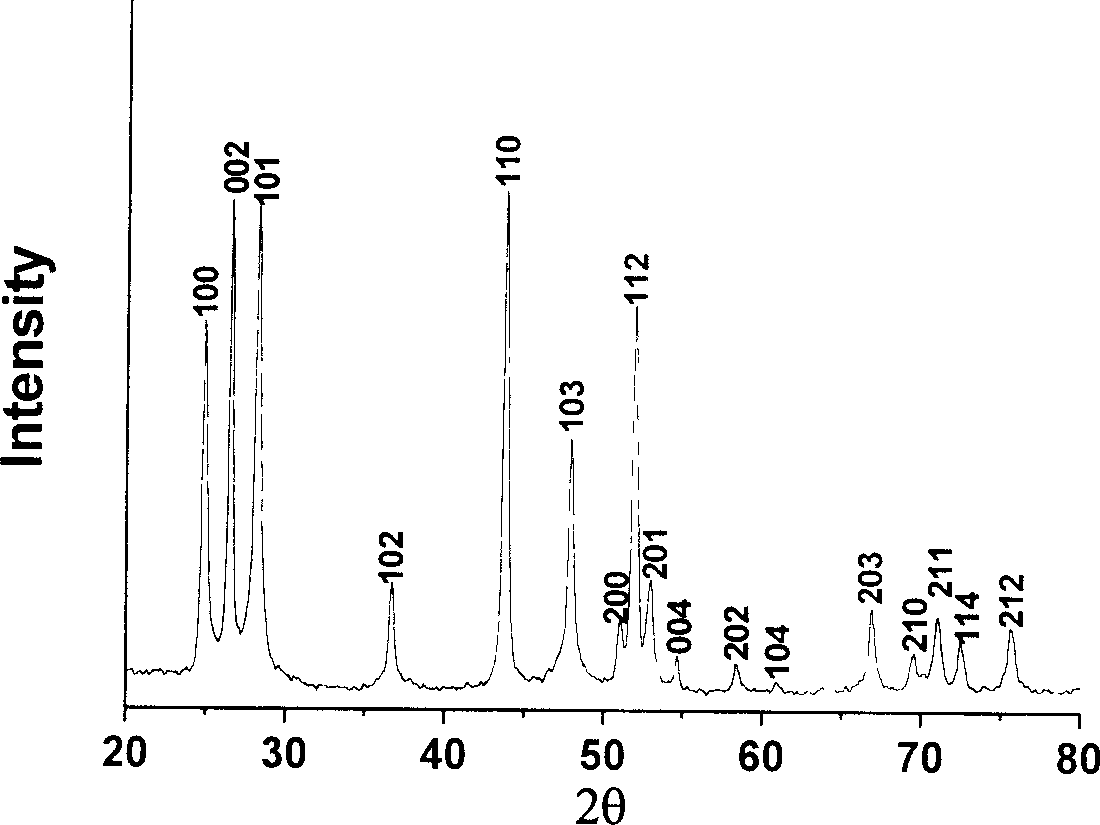

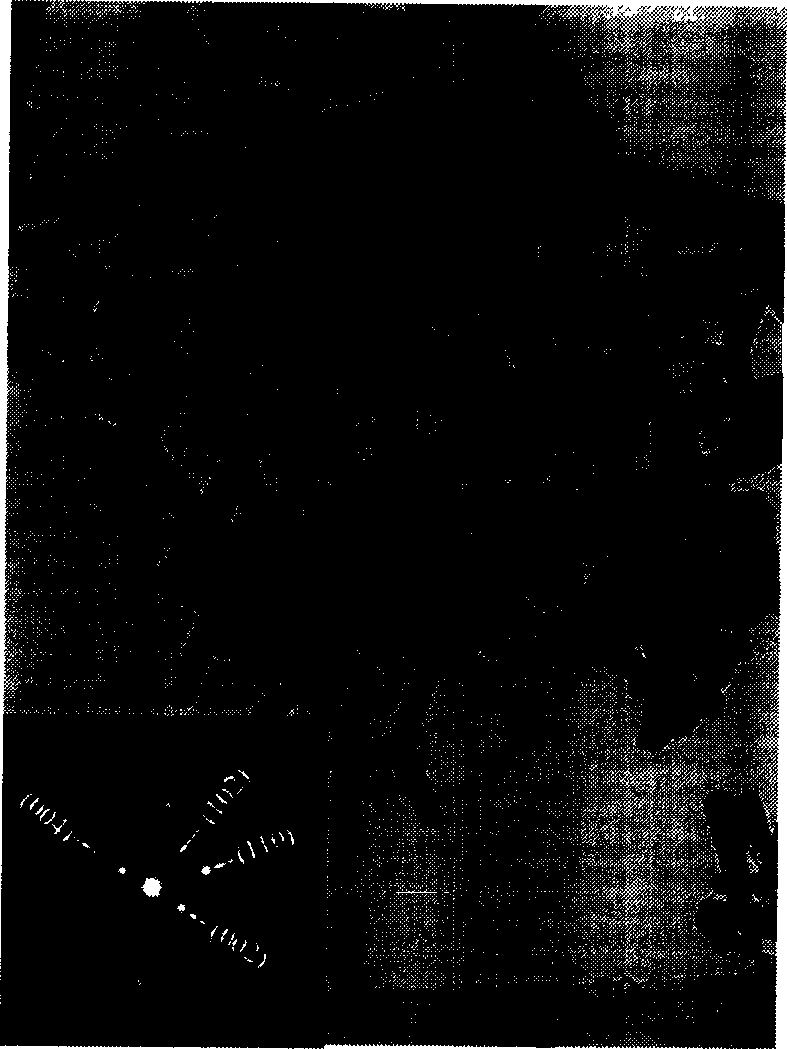

[0014] Add 50 μL of mercaptoacetic acid to 60 ml of 0.01M cadmium sulfate solution, stir for 10 minutes, then add 60 ml of 0.01M sodium sulfide, put the above prepared solution in an autoclave, and treat it at 150°C for 60 hours, The treated solution was centrifuged and dried. The X-ray diagram of the obtained material, the electron microscope photo is shown in figure 1 , figure 2 ,From figure 1 The X-ray pattern shown, can prove that the obtained substance is cadmium sulfide, figure 2 The transmission electron micrographs shown can prove that the obtained material is cadmium sulfide nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com