Integrated coil inductors for ic devices

A technology of integrated circuits and coil components, used in inductors, fixed inductors, printed inductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a multi-turn solenoidal inductor integrated in a semiconductor chip and its manufacturing method, which will now be described in more detail with reference to the accompanying drawings of this application. It should be noted that in the drawings, the same and / or corresponding components are marked with the same reference numerals.

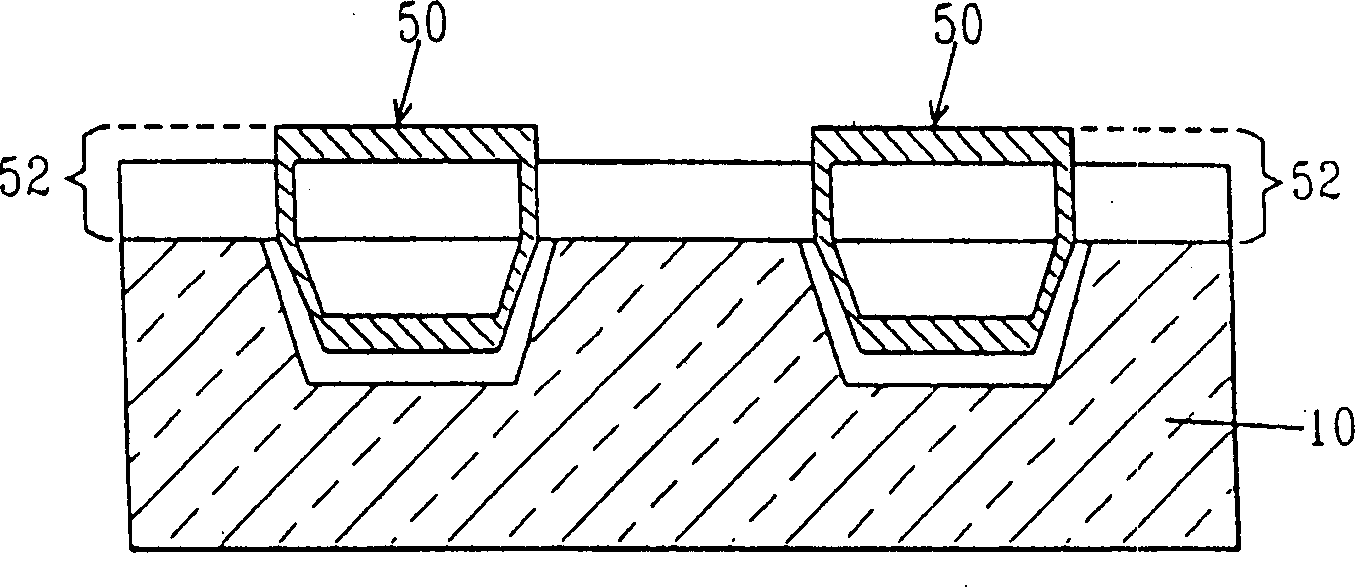

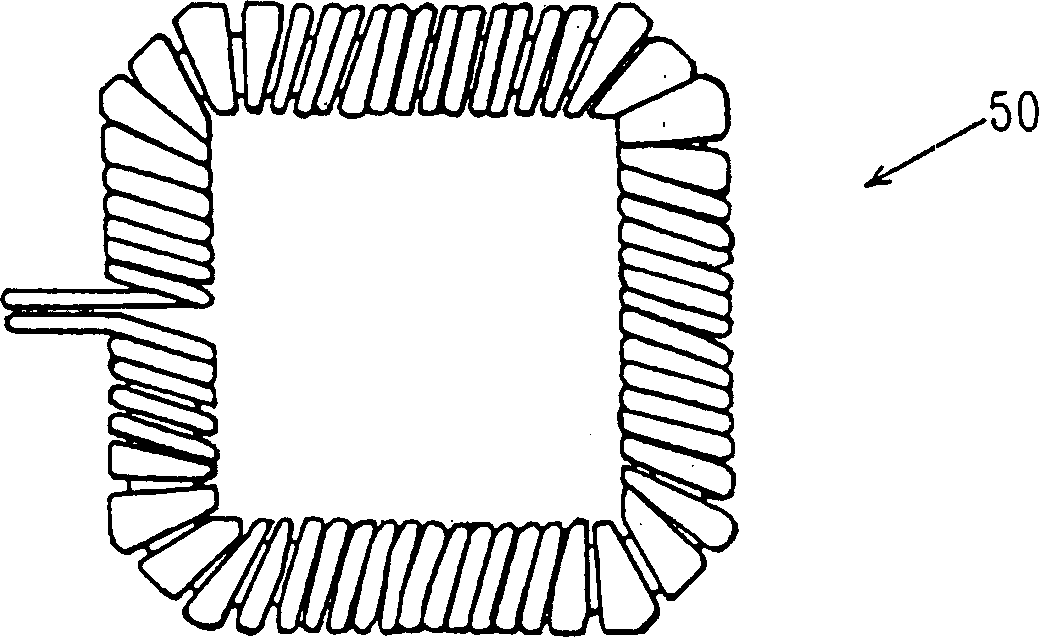

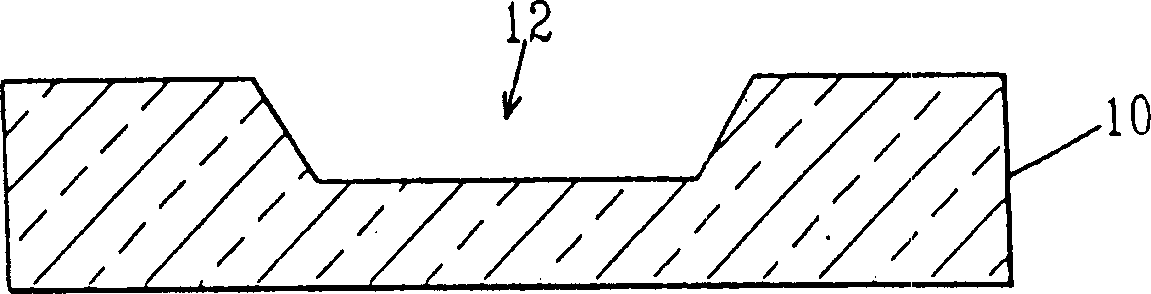

[0024] Reference is first made to the description of the semiconductor structure of the present invention Figure 1A (cross-sectional view) and 1B (top view). specifically, Figure 1A The structure in includes a substrate 10 having one or more solenoidal coils 50 formed in cavities formed in the substrate, partly in a BEOL wiring layer 52 . as an example, Figure 1A A top view of the solenoid coil 50 is shown in Figure 1B middle.

[0025] According to the present invention, each solenoid coil 50 includes a lower coil assembly 22 and an upper coil assembly 30 , which are electrically connected via a side coil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com