Refuse incineration method for mixing and incinerating refuse by using coal-fired circulating fluidized bed boiler and its equipment

A circulating fluidized bed and waste incineration technology, applied in the field of waste incineration, can solve the problems of large investment, poor reliability, serious environmental pollution, etc., and achieve the effects of low investment, prevention of equipment corrosion, and simple equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

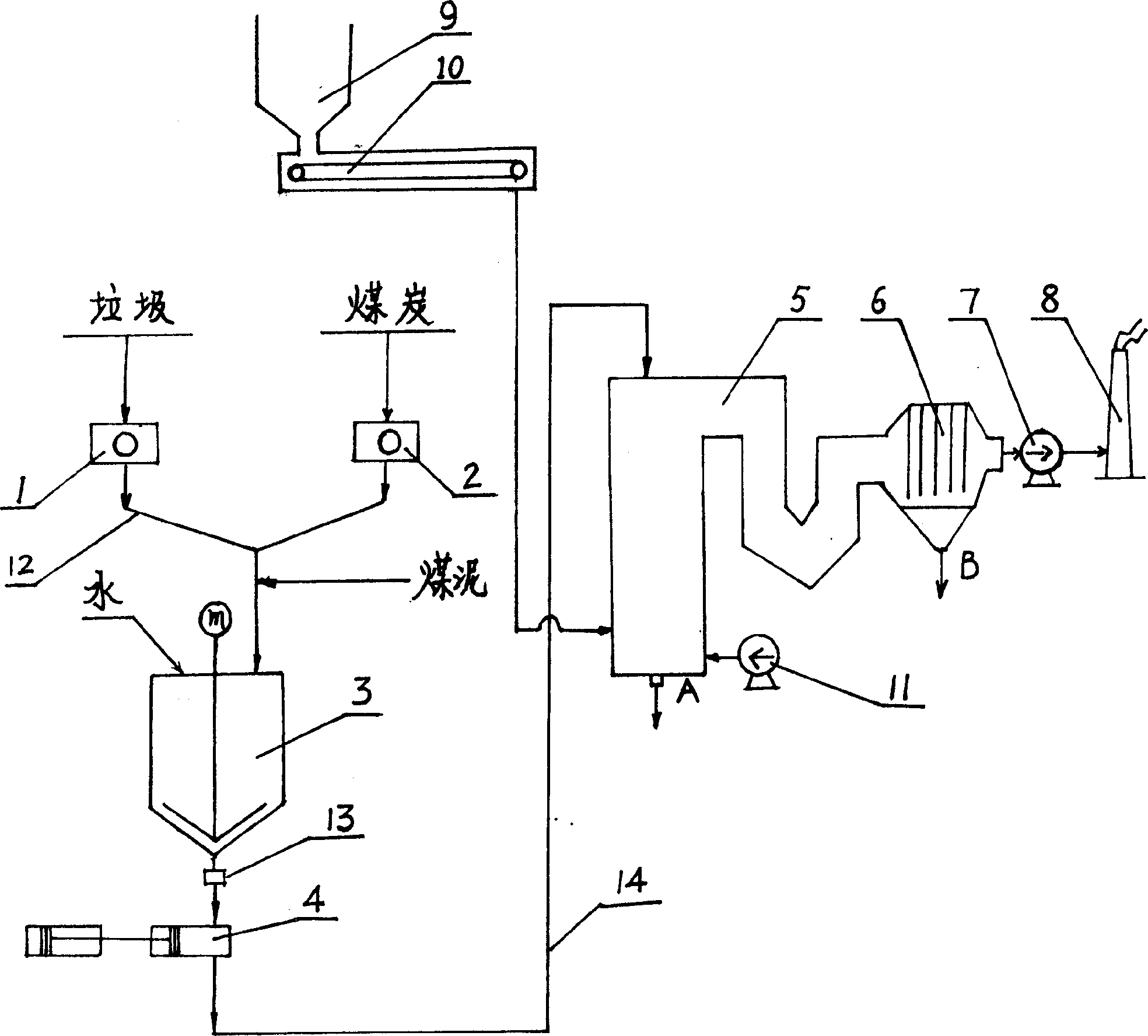

[0017] The following combination figure 1 The present invention is described in detail:

[0018] The main fuel of the circulating fluidized bed boiler is coal, the particle size is ≤10mm, and CaCo is mixed with less than 0.5mm 3 After that, it is stored in the coal bunker 9, sent to the bottom of the furnace by the coal feeder 10, and burns in a fluidized state at a temperature of 850-900°C. Due to the combustion-supporting effect of the secondary air, the unburned CO, CH 4 and H 2 Further combustion releases heat in the middle and top of the furnace, where the temperature exceeds 850°C. The sorted combustible garbage is crushed by the pulverizer to less than 50mm, and sent to the mixing tank 3 together with coal slime or materials similar to coal slime and pulverized coal smaller than 5mm from the coal pulverizer, and then stirred to a water content of 30-40 after adding water. % of the paste is sent into the large-diameter slow-speed hydraulic plunger pump 4 by the feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com