Pond cheanser possesing capability of determining dirt

A cleaning and fouling technology, used in swimming pools, public buildings, gymnasiums, etc., can solve the problems of high labor intensity, waste of water resources, low cleaning efficiency, etc., and achieve high reliability, strong versatility and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take, for example, a pool cleaner equipped with a charge-coupled CCD camera with dirt discrimination capabilities.

[0022] The present invention uses a charge-coupled CCD camera to continuously capture the image of the part to be cleaned directly in front of and below the crawling direction of the cleaner during the working process of the cleaner, and converts it through A / D to form a gray scale of up to 256 levels and is compatible with The pre-stored pool bottom standard image information is continuously compared, and finally processed by the computer system to control the crawling speed of the washer, so as to achieve the purpose that the washer can apply different cleaning forces to different dirt distributions.

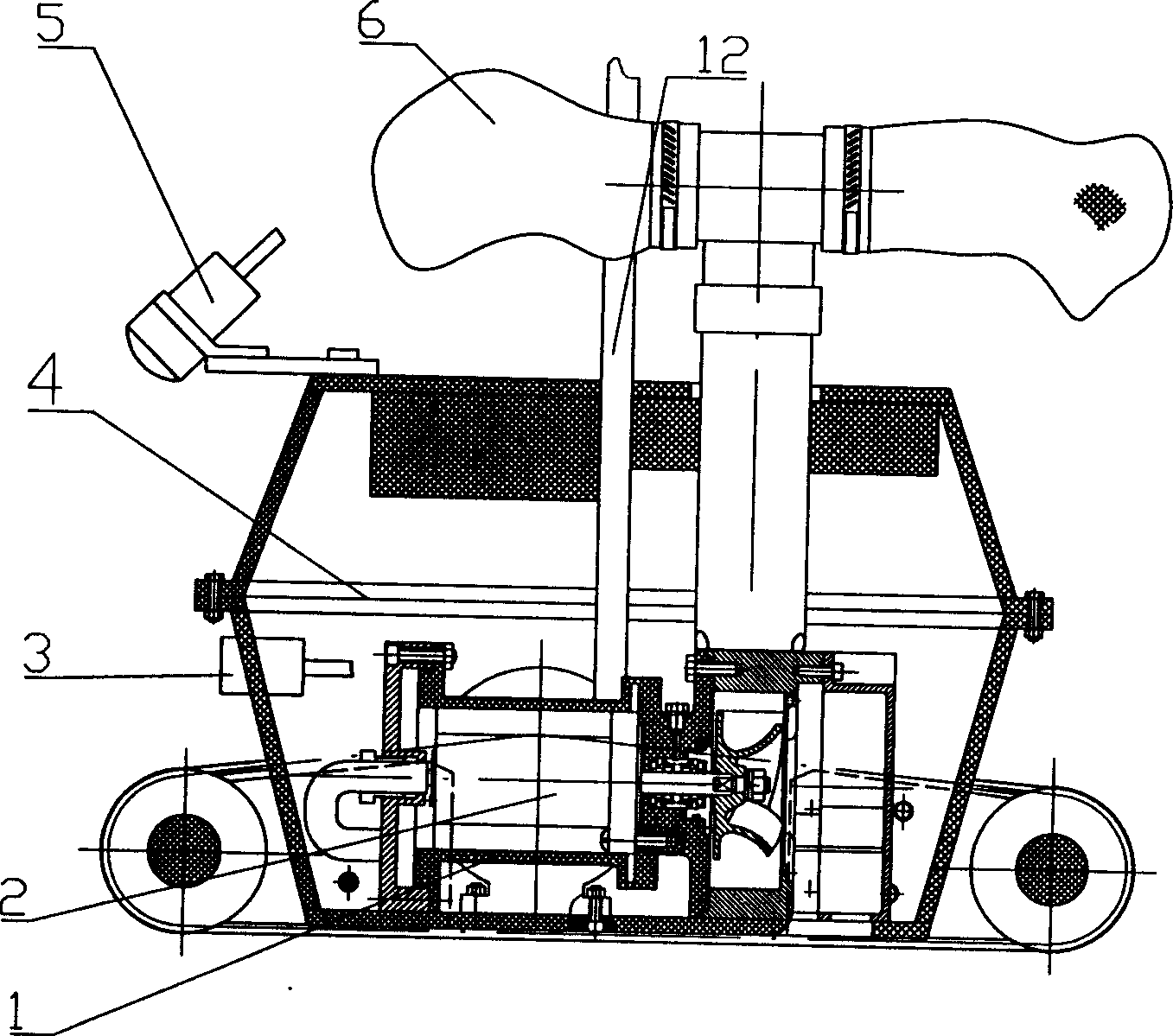

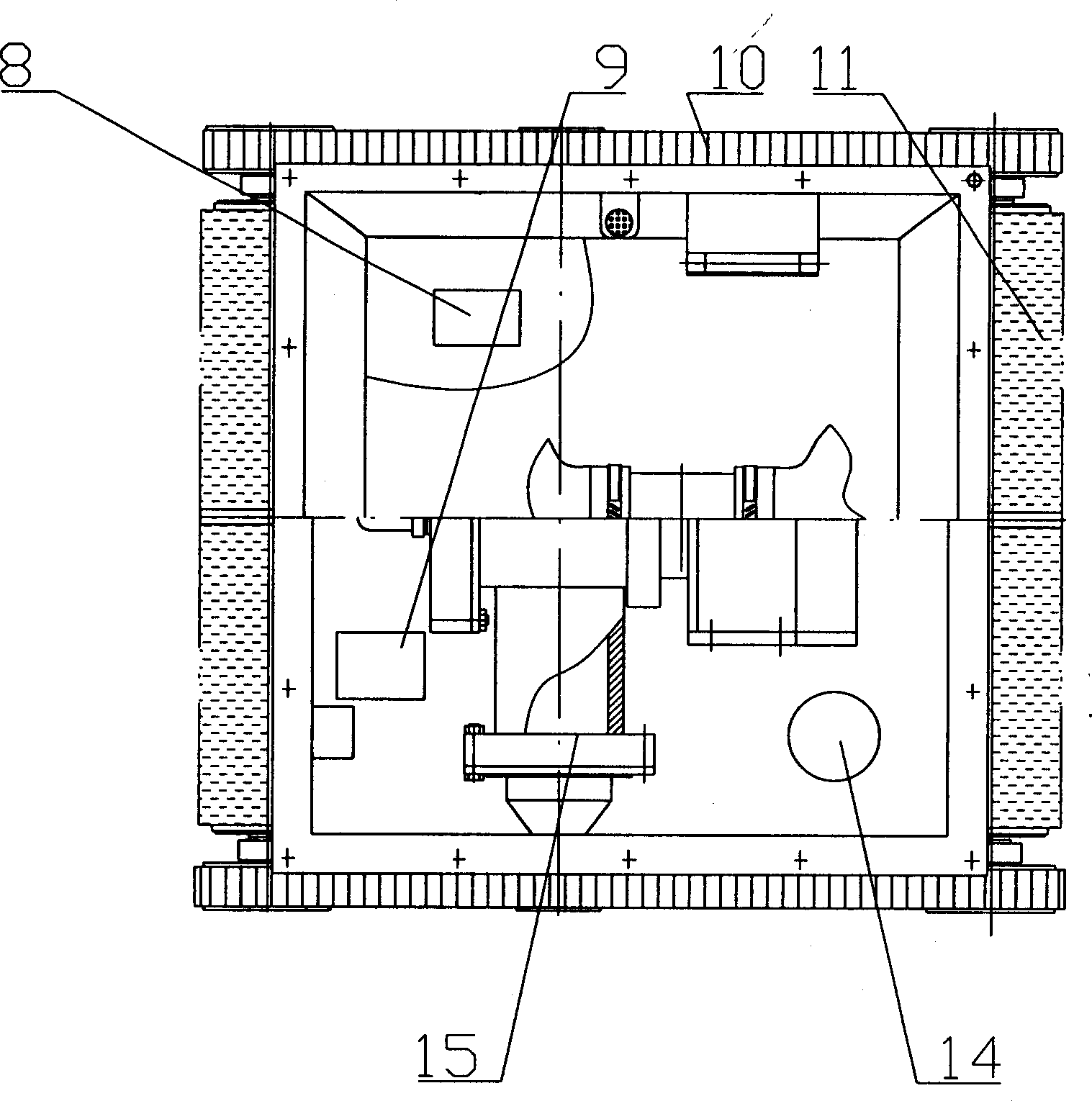

[0023] like figure 1 , 2 As shown, it is a schematic structural diagram of a pool cleaner equipped with a charge-coupled CCD camera with the ability to discriminate dirt. CCD camera 5, water circulation outlet and filter bag 6, industrial control comput...

Embodiment 2

[0033] Take, for example, a pool cleaner with a dirt discrimination capability equipped with a dedicated turbidity sensor.

[0034] In this embodiment, a special turbidity sensor is adopted, and the suspended water flow caused by the scrubbing of the front-end roller brush and the joint action of the water pump suction port on the dirt during the operation of the washer is used as the discrimination object, and the water flow formed by the washer in this state is detected in real time The turbidity of the water quality, using the light-sensitive principle of the photocell, converts the turbidity of the water flow into a voltage signal, and sends it to the computer control system for processing to control the crawling speed of the washer. This achieves the requirement of applying different cleaning strengths for different degrees of dirt.

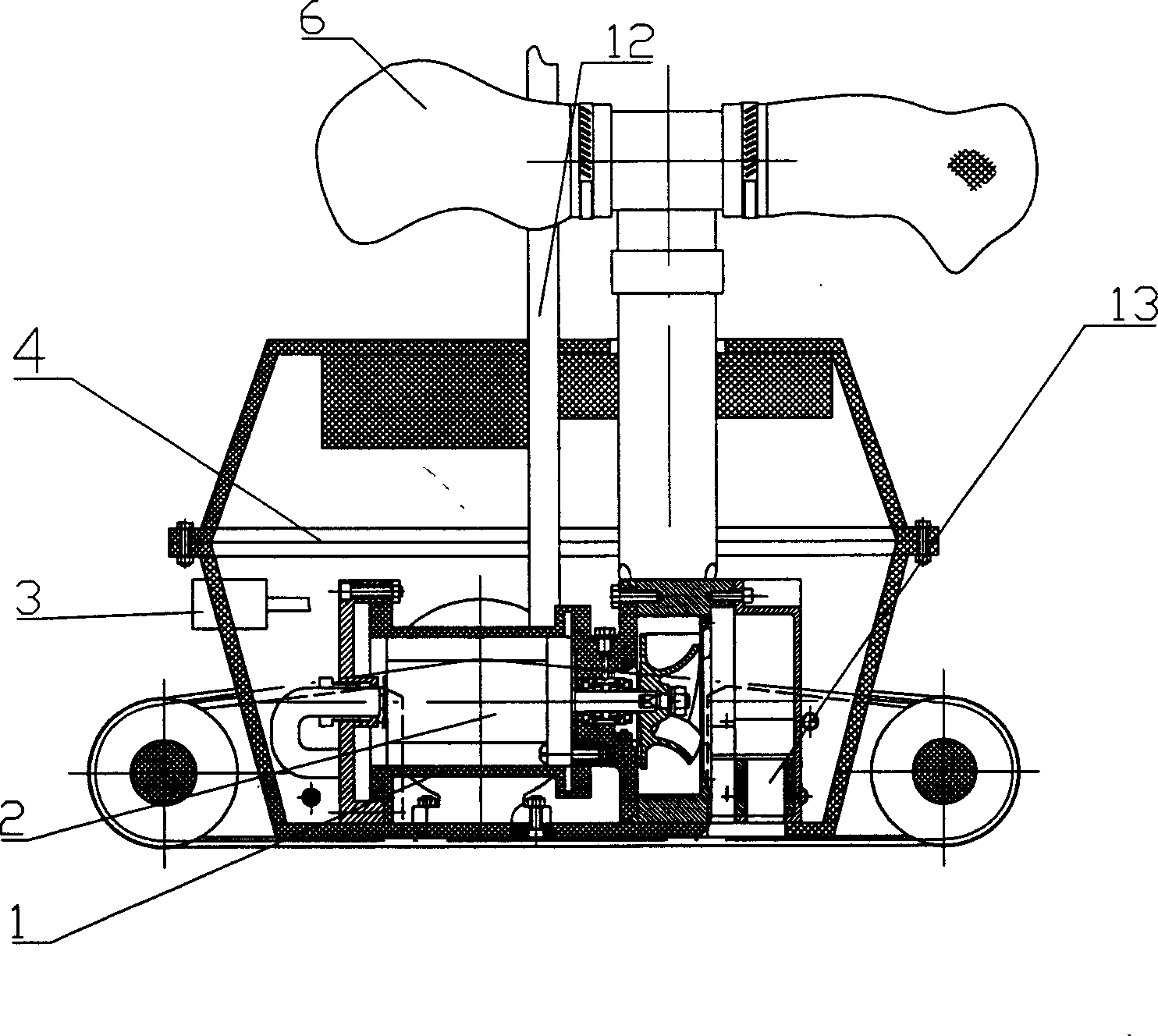

[0035] like figure 2 , 3 As shown, it is a structural schematic diagram of a pool cleaner equipped with a special turbidity sensor with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com