Technology for preparing cell-level high purified nickel sulfate by the selective leach of water quenching high grade nickel and sulfuric acid

A selective, nickel sulfate technology, applied in the field of hydrometallurgy, can solve problems such as the difficulty in producing battery-grade high-purity nickel sulfate, and achieve the effects of high labor production efficiency, good product quality, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below using the drawings and examples.

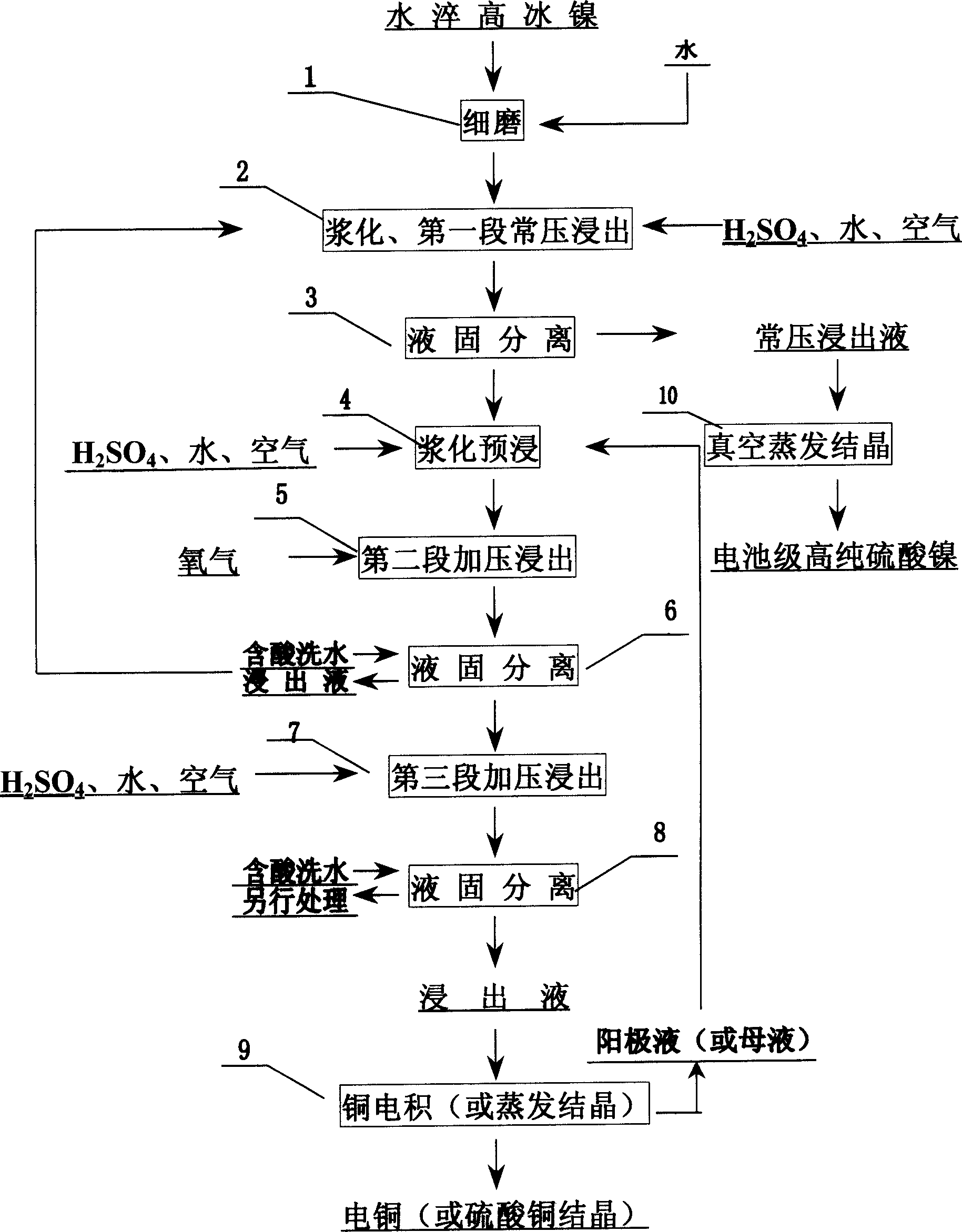

[0026] refer to figure 1 , the process of preparing battery-grade high-purity nickel sulfate by selective leaching of high matte nickel sulfuric acid by water quenching includes the following steps in turn:

[0027] Water crushing high nickel matte fine grinding process 1 adopts two-stage overflow ball mill self-flow series open-circuit fine grinding;

[0028] The first normal-pressure leaching process 2 is to flush the finely ground high-matte pulp with water and the leaching solution of the liquid-solid separation process 6 into the pulping tank, continuously feed air into the pulping tank, add 93% sulfuric acid, stir evenly, and Atmospheric pressure leaching tank for the first stage of normal pressure leaching;

[0029] Liquid-solid separation step 3 is to send the first stage of atmospheric pressure leached pulp to a thickener for liquid-solid separation, and the separated fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com