Method and apparatus for exhaust gas treatment in chemical vapor deposition / chemical gas phase penetration processes

A technology for process tail gas and treatment equipment, applied in chemical instruments and methods, separation methods, gaseous chemical plating, etc., can solve the noise pollution of high pumping rate water ring pumps, the difficulty of replacing pump oil and maintenance, and reduce CVD/CVI Equipment efficiency and other issues, to achieve the effect of noise-free life and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

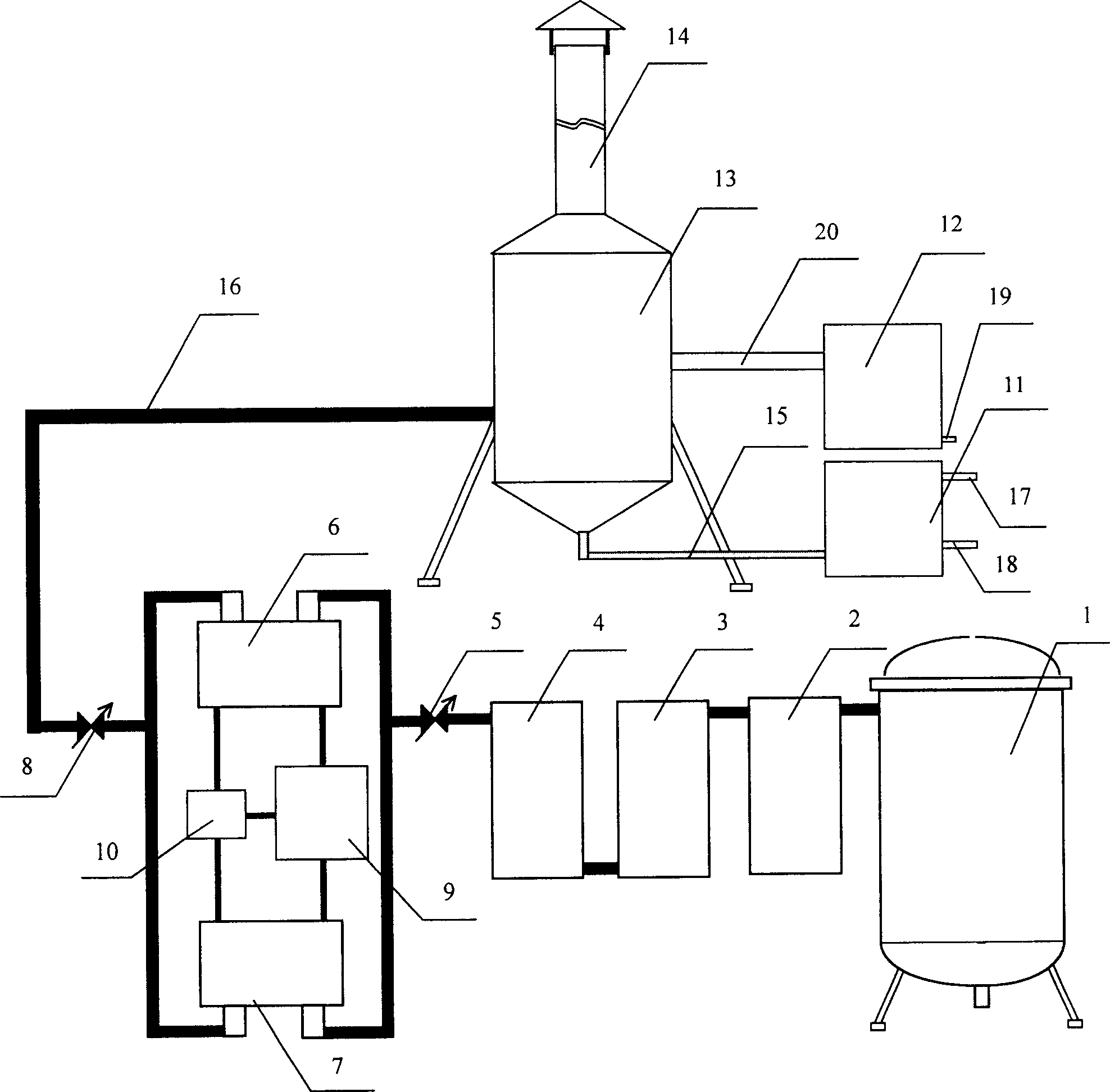

[0011] The steam filter device mainly includes three parts: a steam generator, a reaction tank and a water tank. The steam generator has two types: ultrasonic atomization and heating evaporation. Ultrasonic atomization can use industrial humidifiers, while heating and evaporation can use small industrial boilers. The tail gas discharged from the furnace cavity enters the mechanical pump after being filtered by oil and two-stage solids. The tail gas discharged from the mechanical pump and the steam generated by the steam generator enter the reaction tank at the same time, but the introduction position of the steam should be slightly higher than the introduction position of the tail gas. . The HCl in the tail gas reacts with water vapor, condenses at the same time, and accumulates at the bottom of the reaction tank to form a dilute hydrochloric acid solution. The reaction tank is connected with the water tank through the connector, and the dilute hydrochloric acid enters the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com