Method for recovering tetramethyl guanidine

A technology of tetramethylguanidine and extraction solvent, which is applied in the field of recovery of tetramethylguanidine, can solve the problems of increased environmental burden and waste, and achieve the effect of improving recovery rate and weakening the occurrence of hydrolysis reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

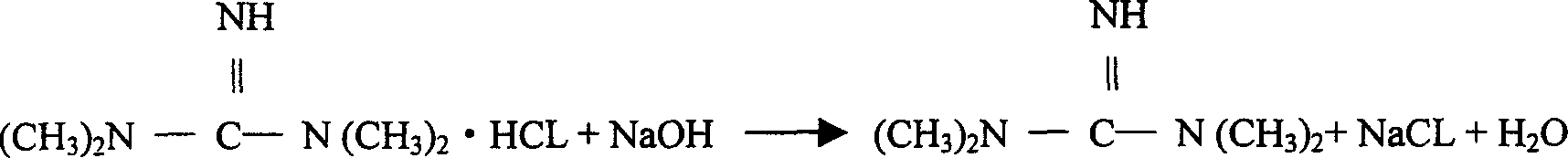

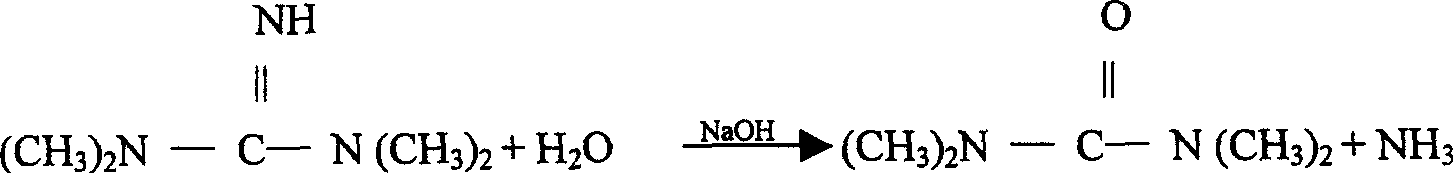

Method used

Image

Examples

Embodiment 1

[0027] 1) Concentrate in a 2000ml four-necked flask, add 1200 grams of tetramethylguanidine-containing wastewater produced at the time of synthesizing cephera, neutralize it with sodium hydroxide or hydrochloric acid aqueous solution to a pH of 6-7, and distill under reduced pressure to remove it. Of the water to produce solid salt.

[0028] 2) Reduce the solid salt, transfer it to a 1000ml four-necked flask, add 400ml of toluene, add a water separator and a dropping funnel, stir quickly, add dropwise 45ml of 30% sodium hydroxide aqueous solution at 20°C, The dripping is completed within 2 hours. After the reaction is completed, heat and increase the temperature to azeotropically dehydrate until there is no more water out of the water separator. Remove the water separator, install a fractionating column, heat and fractionate under normal pressure, recover most of the toluene solvent, and continue to reuse. The remaining product was further distilled under reduced pressure at 130°C...

Embodiment 2

[0031] 1) Concentrate in a 2000ml four-necked flask, add 1200 grams of tetramethylguanidine-containing wastewater produced at the time of synthesis of cephera, neutralize it with sodium hydroxide or hydrochloric acid to a pH of 6-7, and distill under reduced pressure to remove the content Moisture makes solid salt.

[0032] 2) Reduce the solid salt and smash it into a 1000ml four-necked flask, add 450ml of toluene, add a water separator and a dropping funnel, stir quickly, add dropwise 45ml of 30% potassium hydroxide aqueous solution at 30℃, below As in Example 1, the total recovery rate of tetramethylguanidine is 55.8%.

Embodiment 3

[0034] 1) Concentrate in a 2000ml four-necked flask, add 1200 grams of tetramethylguanidine-containing wastewater produced at the time of synthesis of cephera, neutralize it with sodium hydroxide or hydrochloric acid to a pH value of 6-7, and distill under reduced pressure to remove the content 1000 grams of water.

[0035] 2), reduction Move the concentrate to a 1000ml four-necked bottle, add 400ml of toluene, add a water separator and a dropping funnel, heat to increase temperature, azeotropic dehydration, until there is no more water out of the water separator. The temperature was lowered, and 45 ml of a 30% sodium hydroxide aqueous solution was added dropwise at 40°C, and the addition was completed within 2 hours. The following steps are the same as in Example 1, and the total recovery rate of tetramethylguanidine is 54.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com