A thin-film solar cell and method for preparing same

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficulty in further improving photoelectric conversion efficiency, stability of multi-defect cells, and expensive production costs, so as to improve photoelectric conversion efficiency and facilitate promotion. The effect of application and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

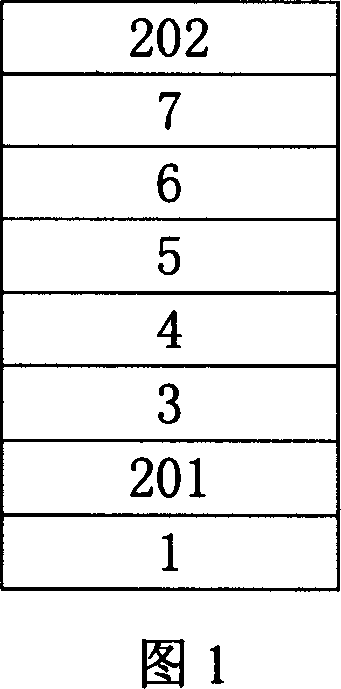

[0020] The thin-film solar cell of the present invention consists of a substrate 1, an electrode 201, a p-type copper indium selenium (CIS) layer 3, an n-type cadmium sulfide (CdS) layer 4, a p-type polysilicon layer 6, an n-type polysilicon layer 7, and an electrode 202. Laminated composition.

[0021] The preparation method of thin film solar cell of the present invention is carried out according to the following steps:

[0022] (1) Prepare a p-type copper indium selenide (CIS) film on the substrate by magnetron sputtering plus vacuum selenization annealing method;

[0023] (2) growing an n-type cadmium sulfide (CdS) layer on a p-type copper indium selenium (CIS) film by vacuum evaporation to form a copper indium selenium / cadmium sulfide (CIS / CdS) composite structure;

[0024] (3) Prepare p-type polysilicon layer and n-type polysilicon layer on the copper indium selenium / cadmium sulfide (CIS / CdS) composite structure by PCVD process and metal-induced solid phase crystallizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com