Method and apparatus for primary shaping composite or modified hollow fibre membrane

A fiber membrane, hollow technology, applied in fiber processing, filament/line forming, chemical instruments and methods, etc., can solve the problem of reduced production efficiency, poor production stability, composite or modified hollow fiber membrane production process can not be carried out continuously and other problems to achieve the effect of improving production efficiency and production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The spinning core liquid is known in the prior art for preparing hollow fiber membranes, and may be dialdehyde aqueous solution or water.

[0040] The liquid in the coagulation bath is a commonly used liquid for coagulating the spinning membrane, which may be water.

[0041] When the method of the present invention is used for one-time composite hollow fiber membrane spinning, the solution in the coating bath is a composite solution or a modified solution, and their types are determined according to the needs of composite membrane making, and the composite solution can be Solutions of polyvinyl alcohol (PVA), polyacrylic acid (PA), cellulose acetate (CA) or hydroxymethyl cellulose (CMC); the modified solution is dialdehyde, diacid, triacid or diisocyanate; Preference is given to using aqueous solutions of the modifying substances. The purpose of adding substances such as dialdehyde, diacid, triacid or diisocyanate is to make polyvinyl alcohol (PVA), polyacrylic acid (P...

Embodiment 1

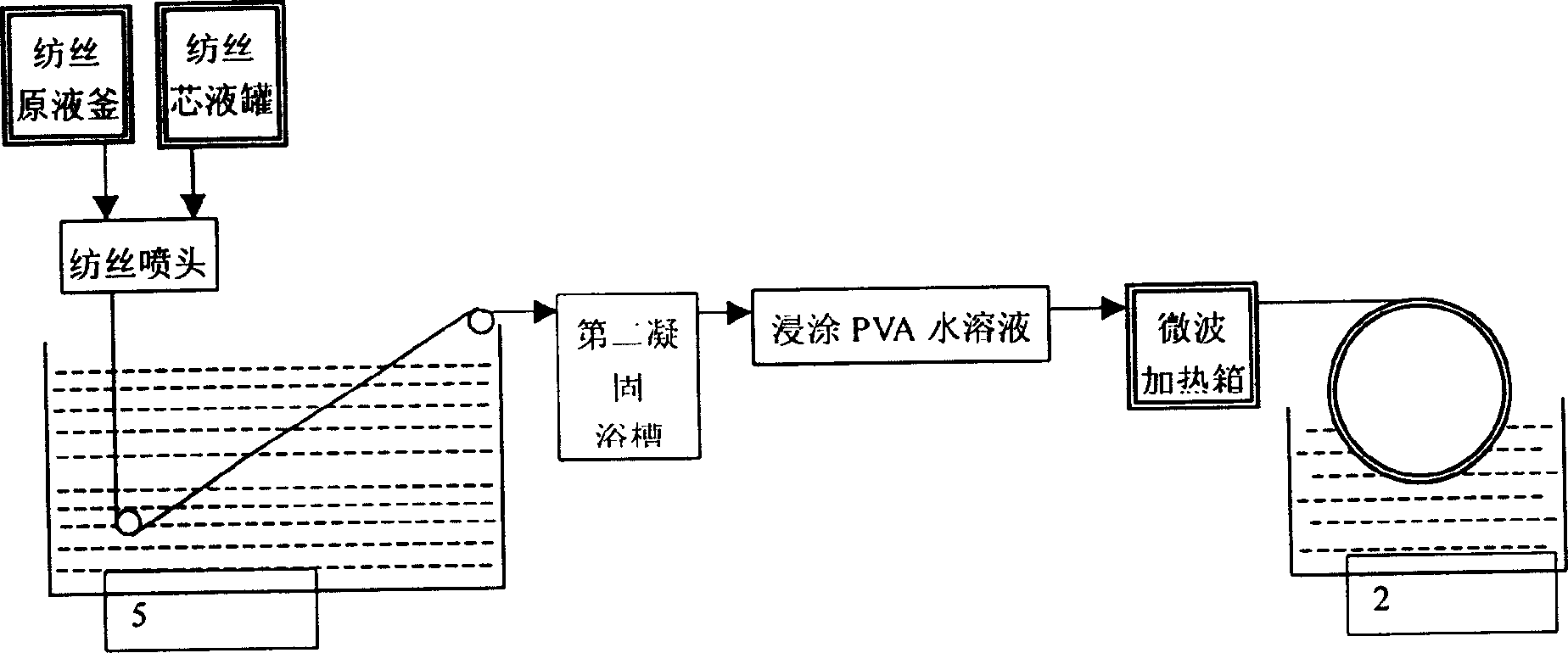

[0051] Embodiment 1: as image 3 As shown, the spinning stock solution is PVDF solution (Solef PVDF 1015 22% by weight, polyethylene glycol 6000 10% by weight, dimethylacetamide 68% by weight), spinning core solution (glutaraldehyde 6% by weight aqueous solution), Coating bath (2% by weight PVA aqueous solution+2% by weight hydrochloric acid), is water in the coagulation bath, the time that passes in the coating bath is 20 seconds, the time that passes through microwave oven is 25 seconds, and temperature is 75 ℃. The method can prepare a PVA composite hollow fiber membrane. The surface of the prepared composite hollow fiber membrane is smooth and has good hydrophilicity. Since polyvinyl alcohol (PVA) macromolecules are not easy to pass through the membrane, the prepared composite hollow fiber membrane is a single-layer composite membrane with membrane The characteristics of small resistance and high separation efficiency. The resulting hollow fiber membrane has a molecular ...

Embodiment 2

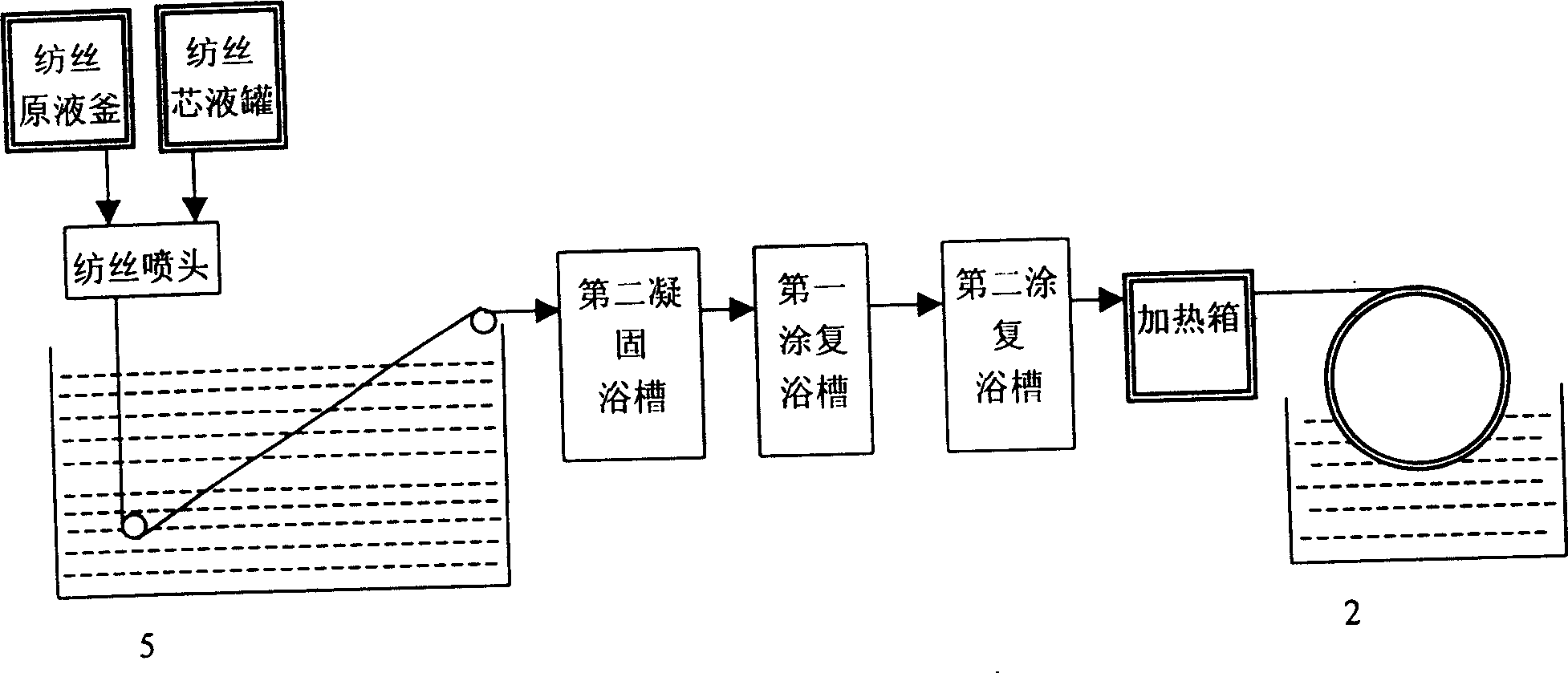

[0054] Embodiment 2: as Figure 4 Shown, spinning dope is polysulfone solution (Udel PS-1700 25% by weight, polyvinylpyrrolidone K-30 10% by weight, dimethylacetamide 68% by weight), spinning core solution (glutaraldehyde 6% by weight Aqueous solution), coating bath (2% weight hydroxymethyl cellulose aqueous solution+2% weight hydrochloric acid, add surfactant soil temperature-20 1 weight %), be water in the coagulation bath, pass through glutaraldehyde 6% weight aqueous solution tank Afterwards, the time for entering into the 2% by weight hydroxymethylcellulose aqueous solution+2% by weight of hydrochloric acid coating bath is 20 seconds, the time for passing through the microwave heating box is 25 seconds, and the temperature is 75°C. The method can prepare a hydrophilic composite hollow fiber membrane. The prepared composite hollow fiber membrane has a smooth surface and good hydrophilicity. The resulting hollow fiber membrane has a molecular weight cut-off of 2000 Dalton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com