Brewer's yeast recombined hepatitis B virus surface antigen stream plus addition femrentation

A technology of hepatitis B surface antigen and brewer's yeast, applied in anti-receptor/cell surface antigen/cell surface determinant immunoglobulin, fermentation, recombinant DNA technology, etc., can solve low cell concentration, low productivity of recombinant HBsAg, unfavorable recombination HBsAg expression level and other issues, to achieve the effect of improving tolerance and improving productivity by weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]Various media were prepared according to the formula shown in Table 1 below, wherein the composition of the basic media was 1.65 g / 53 ml of yeast extract powder, 1.925 g / 53 ml of soybean peptone, and 3.75 ml of 25% glucose. Its preparation method is: take 1.65g of yeast extract powder produced by DIFCO company, 1.925g of soybean peptone produced by Sheffield company, add water to dissolve 49.25ml to constant volume (increased yeast powder and adenine are added in this step). 121°C, 20 minutes for disinfection. After cooling, 3.75 ml of 25% glucose sterilized at 121° C. for 20 minutes was added (increased glucose was added at this step).

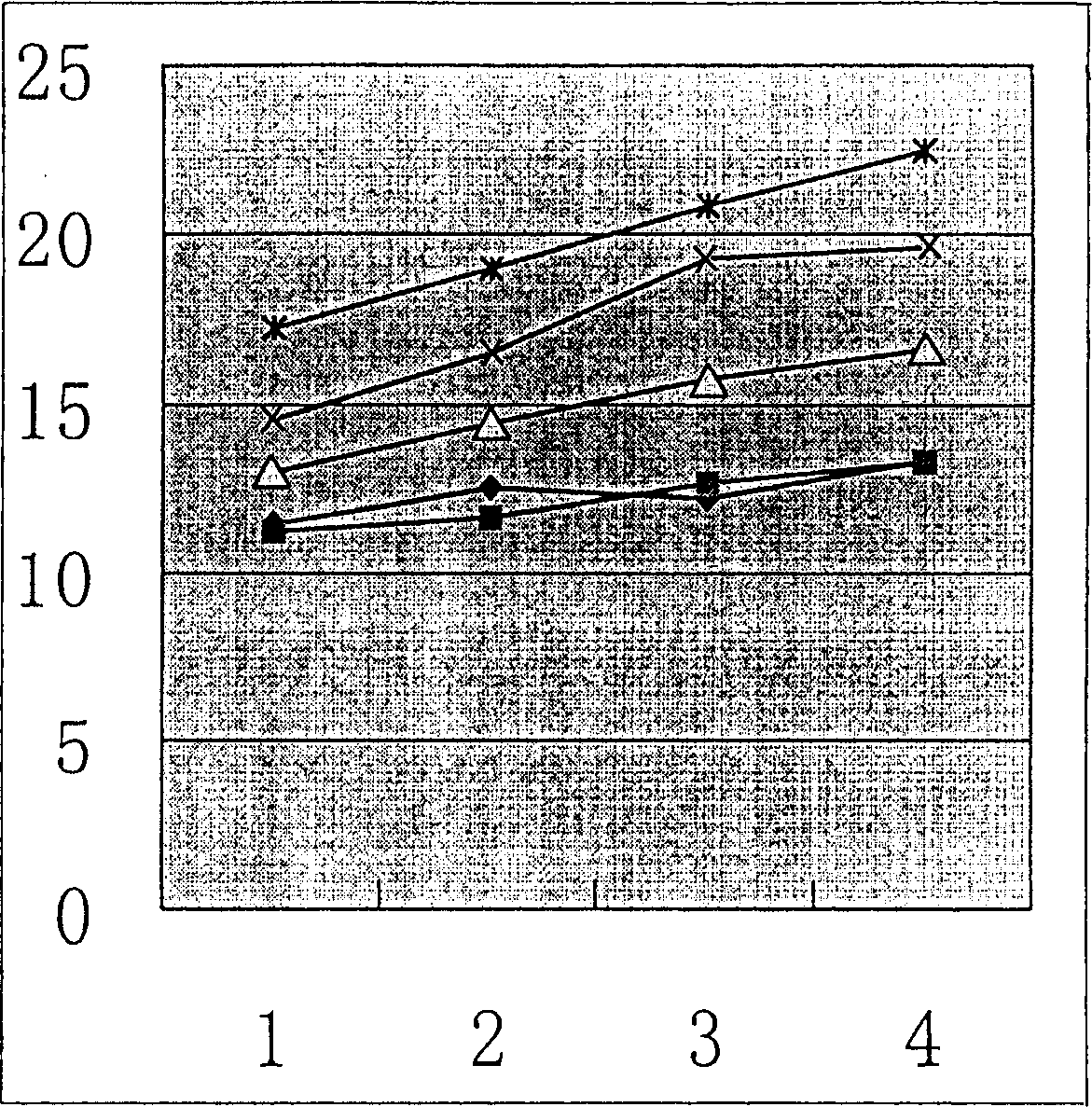

[0048] With the same inoculum size, the recombinant HBsAg engineering strain 2150-2-3 (MATa, adel, leu2-04, cir 0 ) in the culture medium of various formulations shown in the following table 1 in the shake flask, 31,38,48,53 hours sampling survey the OD value of 660nm, the data are summarized in the following table 1:

[0049] ...

Embodiment 2

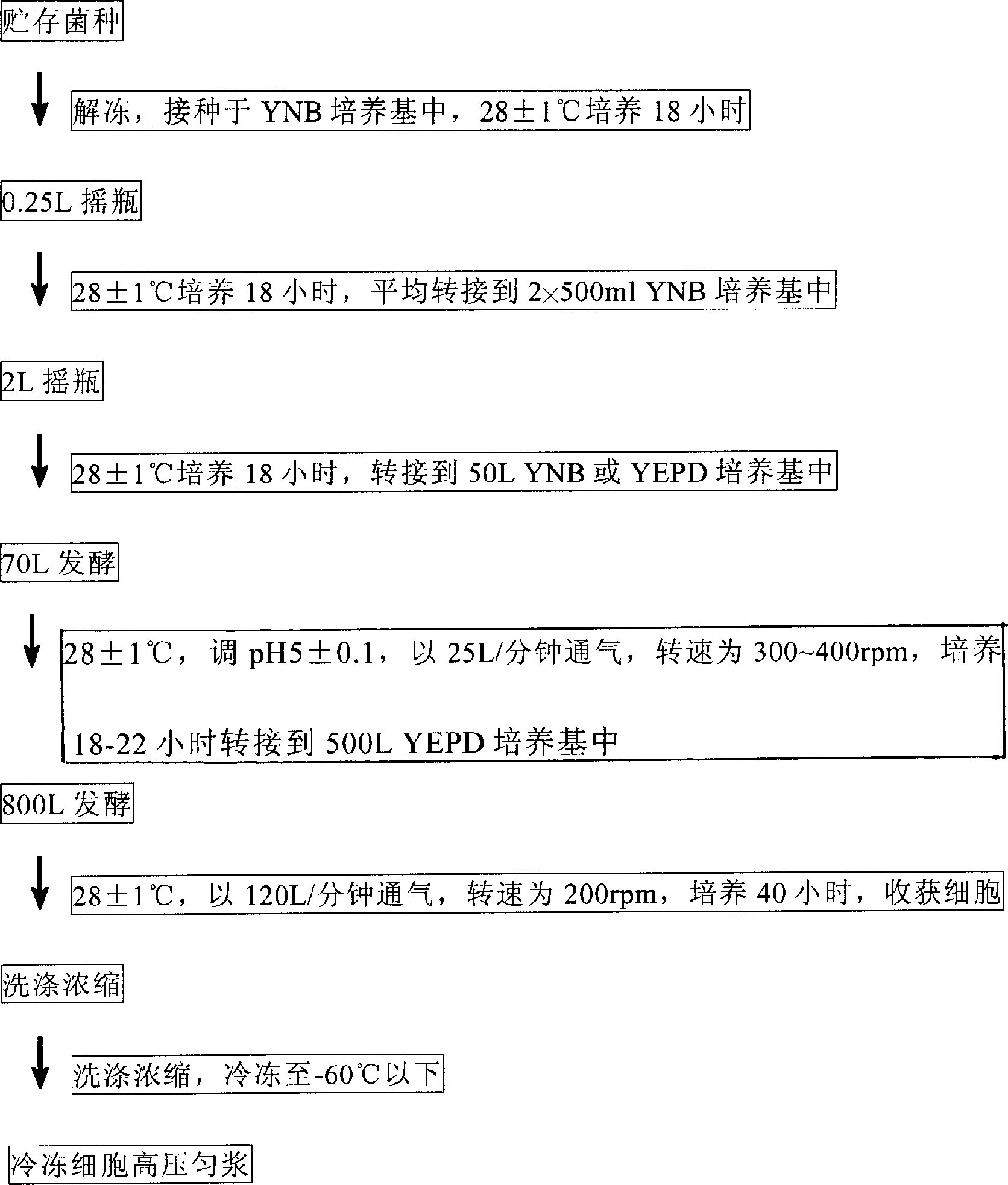

[0052] The seed culture step was basically carried out according to the method described in the "Cell growth" section of Cheryl A. Schulman et. al., Journal of Biotechnology, 21(1991): 109-126). Specifically, the stored strains were thawed, inoculated into 250 ml shake flasks containing 50 ml of 5XLEU selective medium, cultured at 28°C at 350 rpm for 18 hours, and then transferred to two cultures containing 500 ml each. 5XLEU-selective medium in a 2-liter shake flask, and then cultured at 28° C. at 350 rpm for 18 hours. The composition of the 5XLEU-selective medium is the same as that described in the literature Cheryl A. Schulman et.al., Journal of Biotechnology, 21 (1991): 109-126).

[0053] 30 liters of fermentor continuous feeding culture adopts YEPD medium to carry out as follows: Weigh imported natural yeast extract powder (DIFCO company product, article number is 0127-01) 371.2 grams (content in fermented liquid is 32 grams per liter ), 417.6 grams of imported natural ...

Embodiment 3

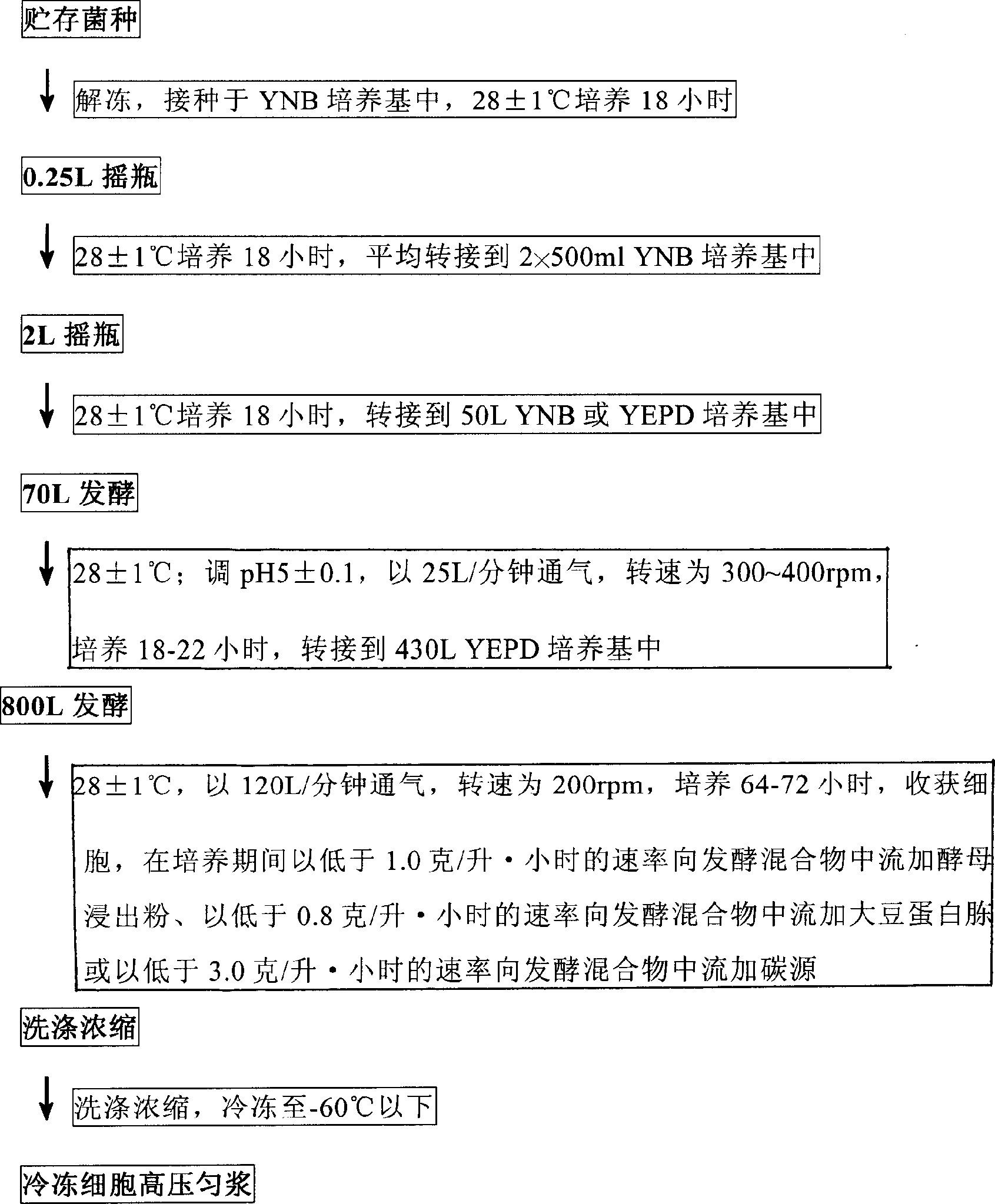

[0055] The cultivation step of seed is with embodiment 2.

[0056] The production and fermentation steps are carried out in the following manner, wherein the source of the materials used, the feeding device, the fermentation temperature, the ventilation rate, the rotation speed of the fermenter, the method for measuring the retention rate of leucine prototroph cells, and the average exogenous gene of the cells The method for the number of plasmid copies and the method for measuring the HBsAg content per liter of fermentation broth are the same as those described in Example 2.

[0057] Continuous feeding culture in 30-liter fermenter: imported natural yeast extract powder 32 g / liter, imported natural soybean peptone 36 g / liter, add water to 9.9 liters, sterilize at 121°C for 30 minutes, after cooling, add sterilized 25 % glucose solution 700 ml, adjust the pH to 6.0 with sterilized 9N phosphoric acid solution. Insert 1 liter of mature seeds, cultivate for 14 hours, and start f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com