Separative purifying method for terephthalic acid

A terephthalic acid and purification method technology, which is applied in the production field of aromatic carboxylic acids in chemical industry, can solve the problems of filter cloth clogging, prolonging the filter operation period, and not having strict requirements for product quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

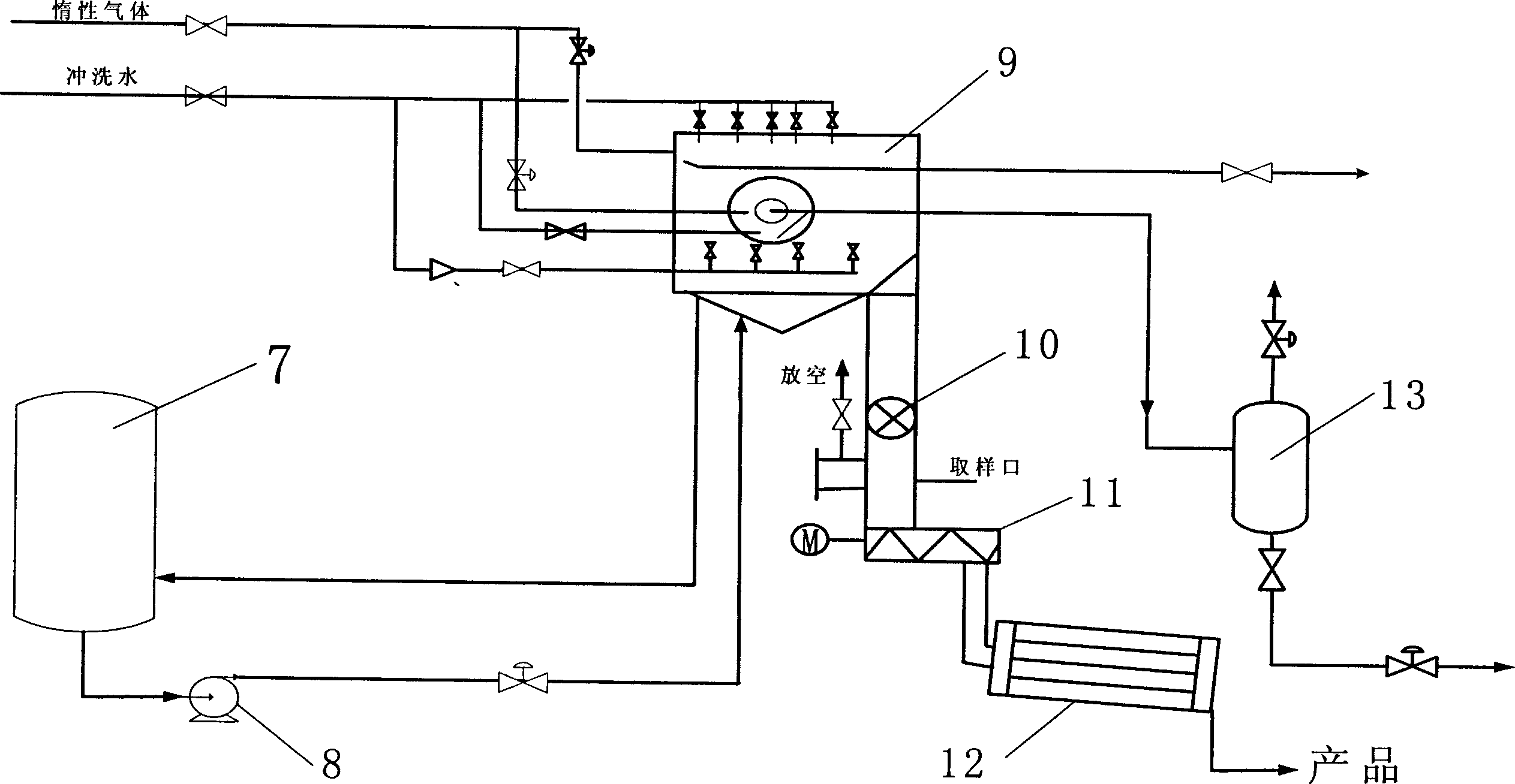

Method used

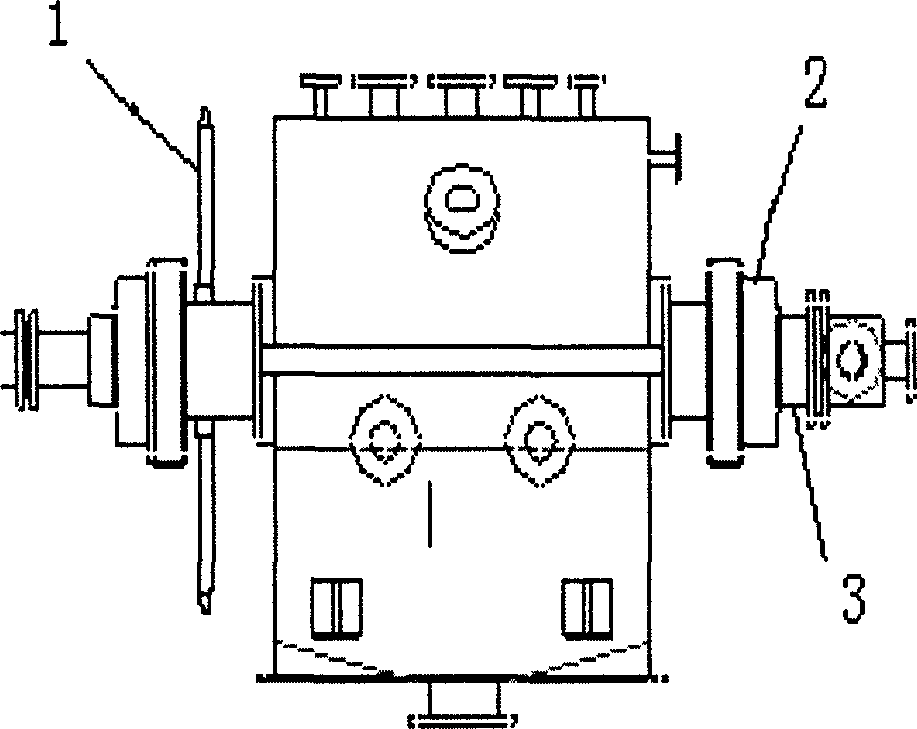

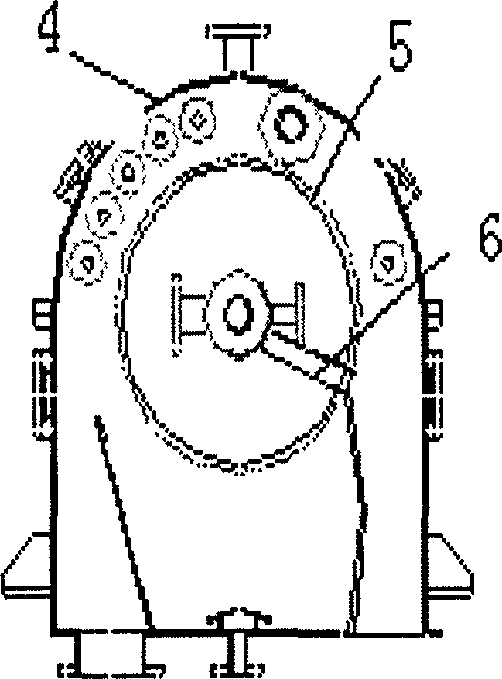

Image

Examples

Embodiment 1

[0031] The terephthalic acid slurry coming out of the crystallizer of the PTA refining unit has a temperature of 151°C and a terephthalic acid concentration of 40%. The difference is 0.04MPa. After a series of processes such as filtration, primary drying, washing, and secondary drying, the impurities in the slurry enter the mother liquor solid recovery system with the mother liquor, and the filter cake enters the dryer through the feeding rotary valve operated under pressure. Material screw, the moisture content of the filter cake is 10%. The content of PT acid in the product is 110mg / kgPTA, the average particle size is 118um, and the product quality is obviously better than that of traditional secondary separation.

Embodiment 2

[0033] The terephthalic acid slurry coming out of the crystallizer of the PTA refining unit has a temperature of 160°C and a terephthalic acid concentration of 40%. The difference is 0.05MPa. After a series of processes such as filtration, primary drying, washing, and secondary drying, the impurities in the slurry enter the mother liquor solid recovery system with the mother liquor, and the filter cake enters the dryer through the feeding rotary valve operated under pressure. Material screw, the moisture content of the filter cake is 8%. The content of PT acid in the product is 100mg / kgPTA, the average particle size is 120um, and the product quality is obviously better than that of traditional secondary separation.

Embodiment 3

[0035]The terephthalic acid slurry coming out of the crystallizer of the PTA refining unit has a temperature of 155°C and a terephthalic acid concentration of 40%. The difference is 0.1MPa. After a series of processes such as filtration, primary drying, washing, and secondary drying, the impurities in the slurry enter the mother liquor solid recovery system with the mother liquor, and the filter cake enters the dryer through the feeding rotary valve operated under pressure. Material screw, the moisture content of the filter cake is 7%. The content of PT acid in the product is 97mg / kgPTA, the average particle size is 116um, and the product quality is obviously better than that of traditional secondary separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com